Heat-insulation material for building external wall and construction method

A technology for thermal insulation materials and building exterior walls, applied in construction, building structure, covering/lining, etc., can solve the problems of high price and difficult promotion and use, and achieve low processing cost, solve surface aging, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

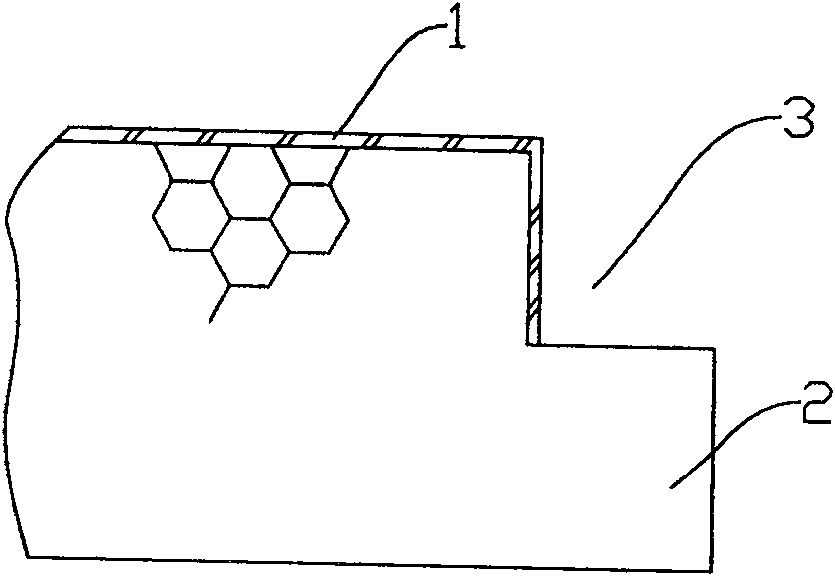

[0026] Embodiment 1: as attached figure 1 , 2 as shown in:

[0027] The thermal insulation material used for building exterior walls described in the present invention is a composite board, and the composite board includes a bottom layer of a closed-cell foam plastic board and a foam bonded on the surface of the closed-cell foam plastic board. Metal panels. In this embodiment, the foamed plastic plate with closed cells is an extruded polystyrene foamed plastic plate, the metal panel is a colored aluminum plate, and the thickness of the colored aluminum plate is 0.5 mm; The thickness of the plastic polystyrene foam board is 30mm.

[0028] The construction method when using the insulation material of the building exterior wall disclosed by the invention as the building insulation system is as follows:

[0029] Making the composite board: firstly, the extruded polystyrene foam board 2 is combined with the metal panel 1 to form a non-folded metal-surface foam composite board u...

Embodiment 2

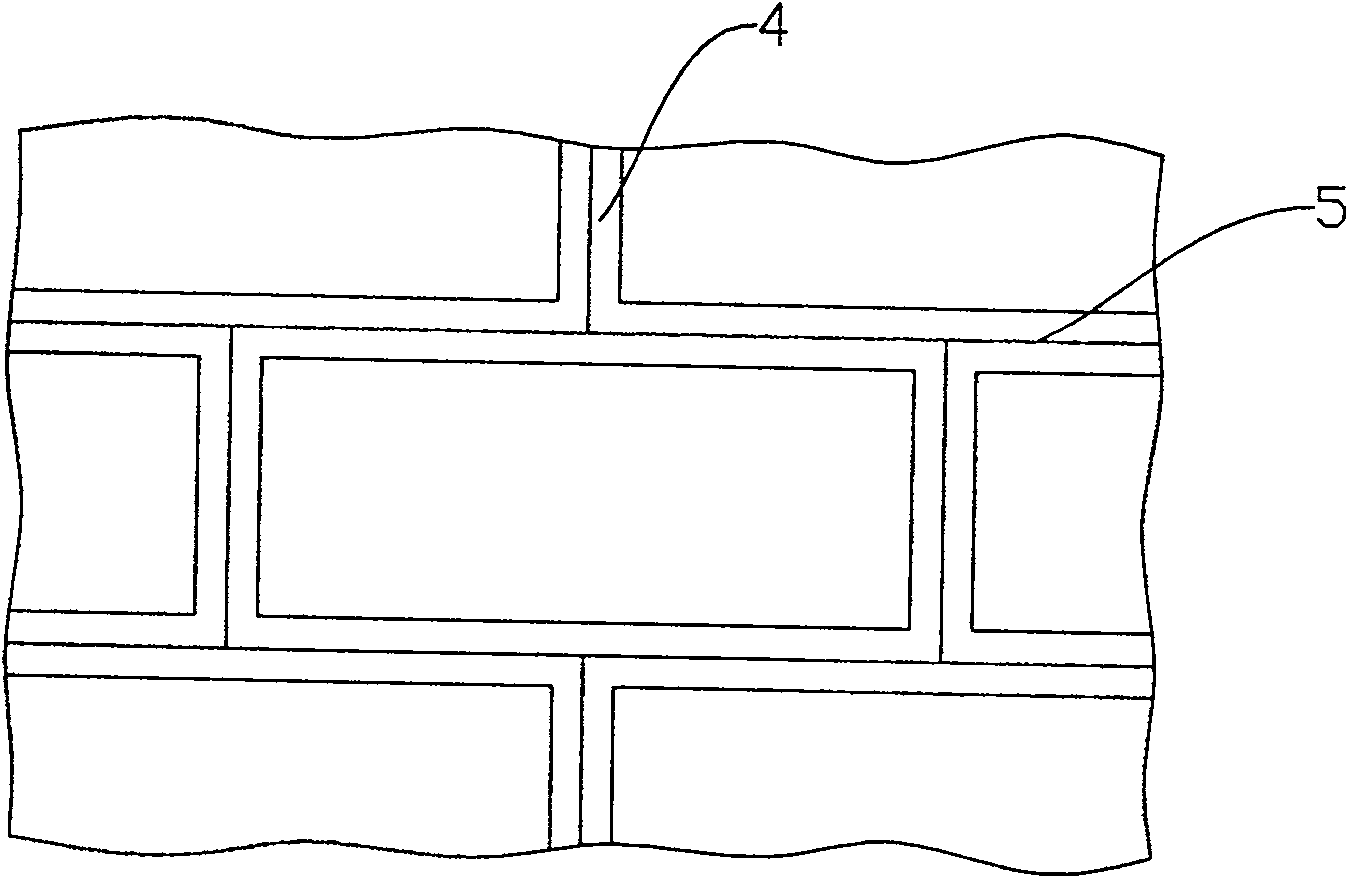

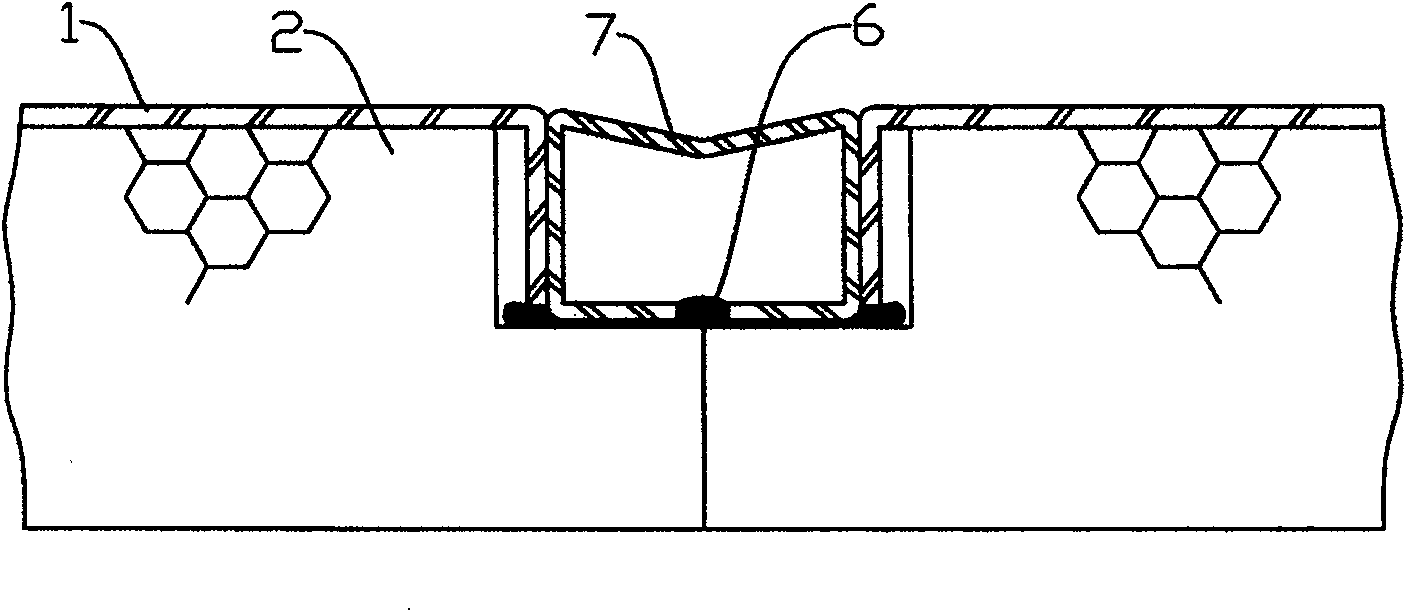

[0030] Embodiment 2: as attached image 3 , 4 shown in

[0031] In this embodiment, the construction method for making the composite board can be as follows: first, a right-angled side groove is arranged on the periphery of the extruded polystyrene foam board, and square openings are cut out at the four sharp corners of the metal panel, And the edge portion of the aluminum plate is bent toward the back side of the aluminum plate to form an aluminum gusset plate shape, and then the extruded polystyrene foam board and the aluminum panel are combined to form a composite panel in which the same panel as in Example 1 is an aluminum gusset plate .

[0032] In this embodiment, the faux aluminum curtain wall is used. Paste the two-layer structure composite board on the leveling layer. Use glass glue 6 to bond aluminum bead 7 or plastic bead at the grooved seam 8 place that forms as sealing member sealing. Adhesive beading can prevent glass glue from aging and also reduce construc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com