An ultra-high weather resistance optical cable

A technology with ultra-high weather resistance and weather resistance, applied in the field of optical cables, it can solve the problems of economic loss, optical fiber exposure, brittleness, etc., and achieve the effect of exerting weather resistance performance, improving application effect, and inhibiting corrosion progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An ultra-high weather-resistant optical cable, which is composed of an optical fiber, an insulating layer, a waterproof layer, a flame-retardant layer, an anti-erosion layer, and an outer sheath from the inside to the outside;

[0025] Wherein, the outer sheath is composed of thermoplastic polyurethane elastomer, nickel-chromium alloy and polyamide; the mass ratio of thermoplastic polyurethane elastomer, nickel-chromium alloy and polyamide in the outer sheath is 10:2:5.

[0026] Among them, the optical fiber is composed of a bare optical fiber and an acrylic resin layer coated on its outer surface, the insulating layer is polyethylene, the waterproof layer is polyvinyl chloride, and the flame-retardant layer is a 105°C radiation cross-linked flame-retardant polyethylene material.

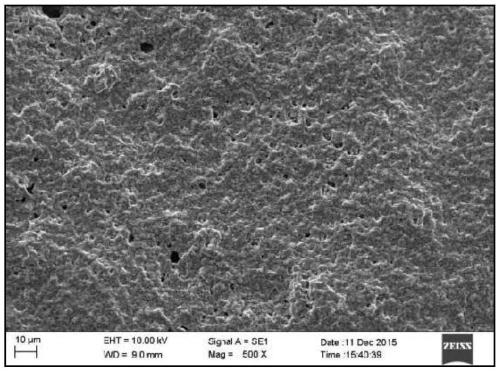

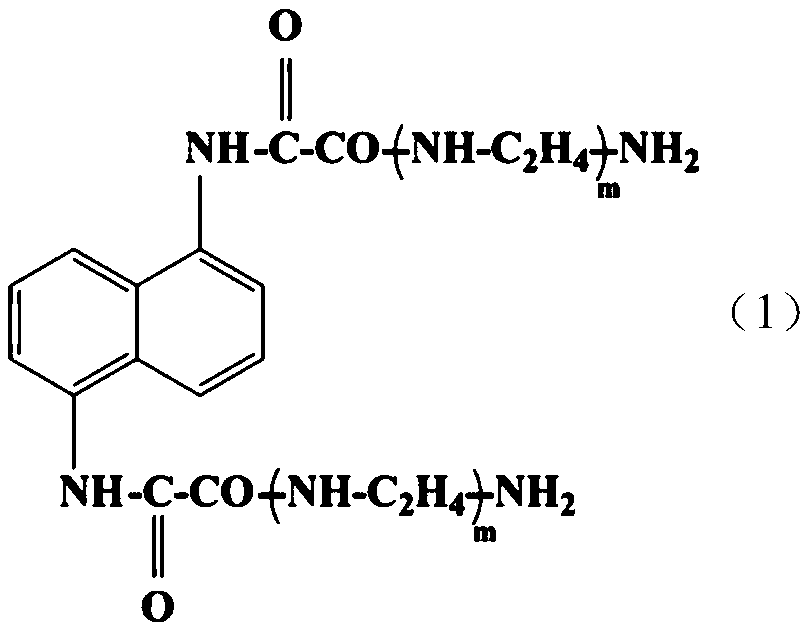

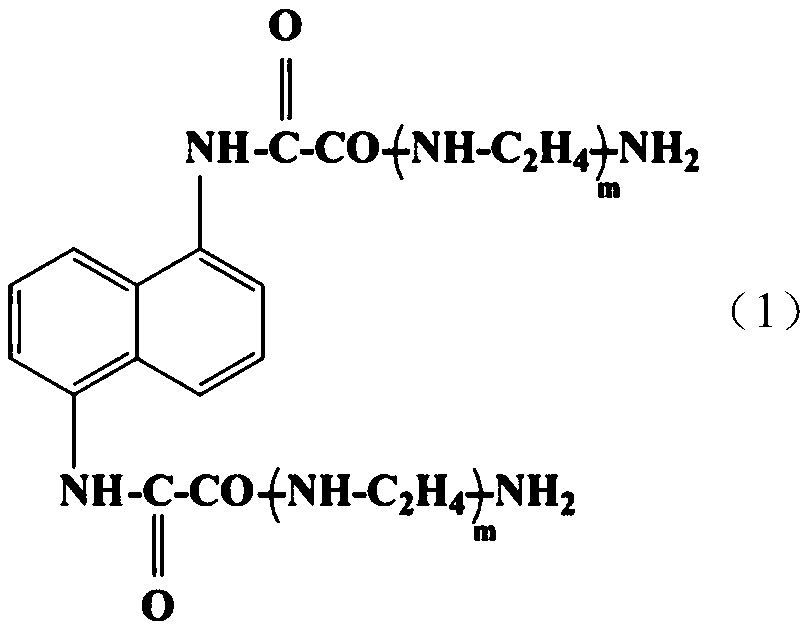

[0027] Among them, the anti-erosion layer is composed of EPDM rubber and the compound with the formula (1), and the mass ratio of the EPDM rubber to the compound with the formula (1) in the an...

Embodiment 2

[0031] An ultra-high weather-resistant optical cable, which is composed of an optical fiber, an insulating layer, a waterproof layer, a flame-retardant layer, an anti-erosion layer, and an outer sheath from the inside to the outside;

[0032] Wherein, the outer sheath is composed of thermoplastic polyurethane elastomer, nickel-chromium alloy and polyamide; the mass ratio of thermoplastic polyurethane elastomer, nickel-chromium alloy and polyamide in the outer sheath is 10:2:6.

[0033] Among them, the optical fiber is composed of a bare optical fiber and an acrylic resin layer coated on its outer surface, the insulating layer is polyethylene, the waterproof layer is polyvinyl chloride, and the flame-retardant layer is a 105°C radiation cross-linked flame-retardant polyethylene material.

[0034] Among them, the anti-erosion layer is composed of EPDM rubber and the compound with the formula (1), and the mass ratio of the EPDM rubber to the compound with the formula (1) in the an...

Embodiment 3

[0038] An ultra-high weather-resistant optical cable, which is composed of an optical fiber, an insulating layer, a waterproof layer, a flame-retardant layer, an anti-erosion layer, and an outer sheath from the inside to the outside;

[0039] Wherein, the outer sheath is composed of thermoplastic polyurethane elastomer, nickel-chromium alloy and polyamide; the mass ratio of thermoplastic polyurethane elastomer, nickel-chromium alloy and polyamide in the outer sheath is 10:3:5.

[0040] Among them, the optical fiber is composed of a bare optical fiber and an acrylic resin layer coated on its outer surface, the insulating layer is polyethylene, the waterproof layer is polyvinyl chloride, and the flame-retardant layer is a 105°C radiation cross-linked flame-retardant polyethylene material.

[0041] Among them, the anti-erosion layer is composed of EPDM rubber and the compound with the formula (1), and the mass ratio of the EPDM rubber to the compound with the formula (1) in the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com