Silicon-cored pipe and preparation method thereof

A technology of silicon core tube and polymer flame retardant, which is used in instruments, optical components, optics, etc., can solve the problem of flame retardant reducing the mechanical properties of silicon core tube, low thermal deformation temperature of polyethylene, and poor resistance to environmental stress cracking. and other problems, to achieve the effect of improving the melt viscosity is too high, improving the safety of use, and excellent resistance to environmental cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

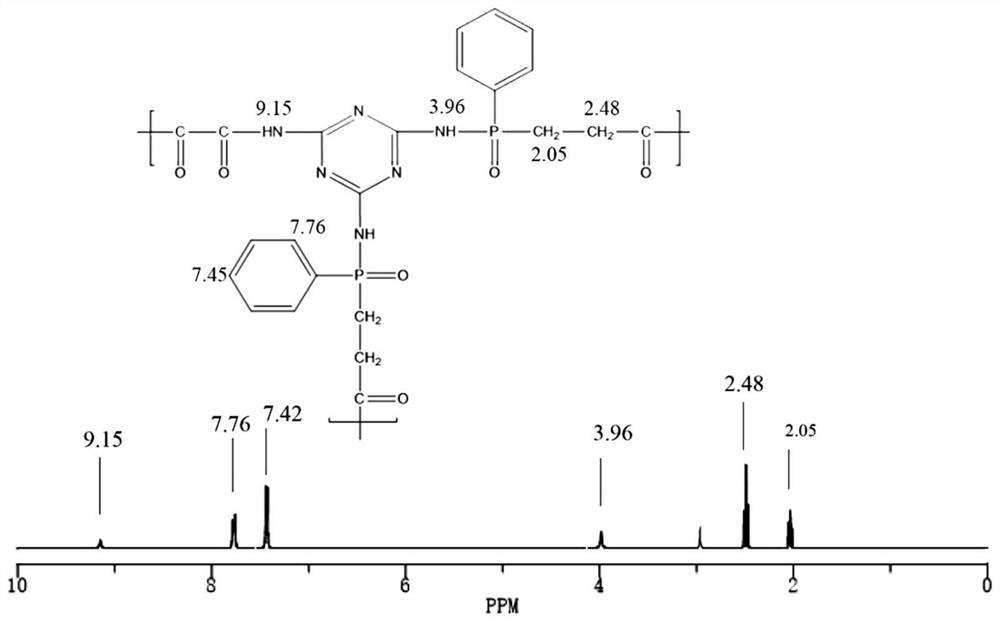

[0076] This embodiment first provides a polymer flame retardant, which is prepared by the following steps:

[0077] 1) Add 7g of oxalic acid to 90g of dimethyl sulfoxide, stir to dissolve, dissolve 5g of melamine in 50g of 35wt% methanol aqueous solution, and add dropwise to oxalic acid at a rate of 0.2mL / s In the solution, stir and react at 60°C and 400r / min for 4h. After the reaction is stopped, the reaction solution is suction-filtered and washed with methanol for 5 times, and then the product is dried in a vacuum oven at 60°C to obtain the amine salt;

[0078] 2) Mix 10g of amine salt with 10g of carboxyethylphenyl phosphoric acid, 2.5g of melamine, and 0.2g of ammonium phosphate, add it to 40g of deionized water, raise the temperature to 155°C under nitrogen protection, and stir at 400r / min for 4h ;

[0079] 3) Raise the temperature to 180°C, react for 2 hours, continue to raise the temperature to 230°C, react at 1.0 MPa for 8 hours, cool the reaction product to room tem...

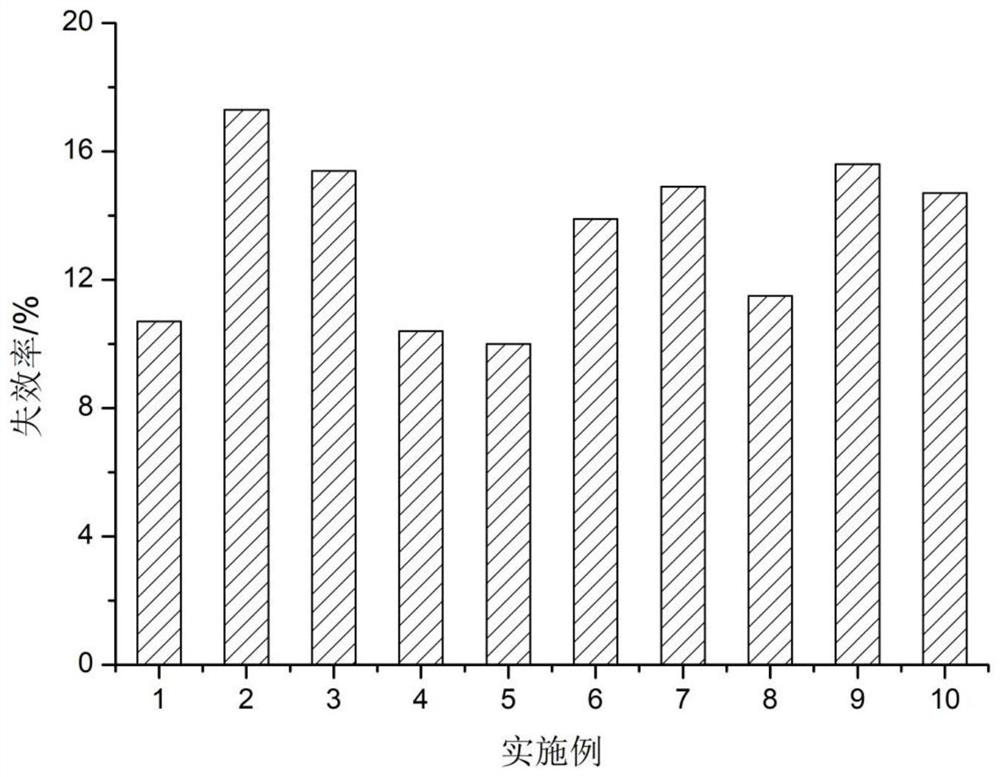

Embodiment 2

[0102] This embodiment provides another silicon core tube. The components and preparation method are basically the same as those in Example 1, except that in this example, during the preparation of benzimidazole carboxylate grafted ultra-high molecular weight polyethylene, benzene The addition of imidazole carboxylate is 1g, that is, the addition weight ratio of ultra-high molecular weight polyethylene and benzimidazole carboxylate is 1:0.1, and the grafting rate of imidazole carboxylate grafted high molecular weight polyethylene is 9.3%. .

Embodiment 3

[0104] This embodiment provides another silicon core tube. The components and preparation method are basically the same as those in Example 1, except that in this example, during the preparation of benzimidazole carboxylate grafted ultra-high molecular weight polyethylene, benzene The addition of imidazole carboxylate is 3g, namely the addition weight ratio of ultra-high molecular weight polyethylene and benzimidazole carboxylate is 1:0.3, and the graft ratio of imidazole carboxylate grafted high molecular weight polyethylene is 19.1% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com