Air blowing detection mechanism for packing bag

A detection mechanism and packaging bag technology, which is applied in packaging and other directions, can solve the problems of reducing the packaging yield, the bottom cannot be opened, and the material is easy to overflow the packaging bag, so as to ensure the running speed and improve the packaging yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

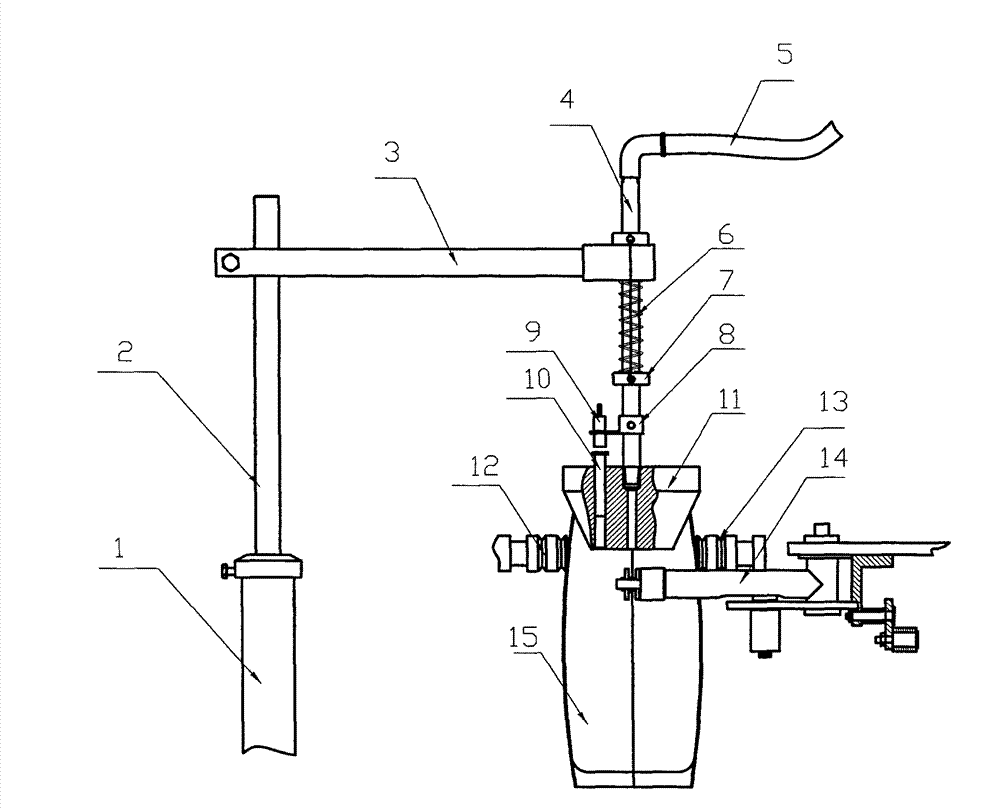

[0007] refer to figure 1 , the present invention is applied to the packaging bag blowing detection mechanism of the bag-type stand-up pouch packaging machine, which includes an outer suction nozzle 12, an inner suction nozzle 13, and a support arm 3. One end of the support arm 3 is equipped with a blowing pipe 4. The below of trachea 4 is equipped with plug post 11 (for taper).

[0008] Wherein, the upper end of the air blowing pipe 4 is connected to the air pump through a flexible pipe 5; on the air blowing pipe 4, a spring 6 and an upper and lower retaining ring 7 are installed at the position of the support arm, which is conducive to the elastic installation and return of the air blowing pipe. position function; the other end of the support arm 3 is connected with the column 1 on the packaging machine through the lifting shaft 2, so that the support arm can perform lifting movement.

[0009] When this mechanism is working, the packaging bag 15 is clamped by the sub-clamp m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com