Unit and method for conveying workpieces along a processing run

一种输送方向、设备的技术,应用在输送机物件、输送机、运输和包装等方向,能够解决增高事故可能性等问题,达到节省空间位置的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

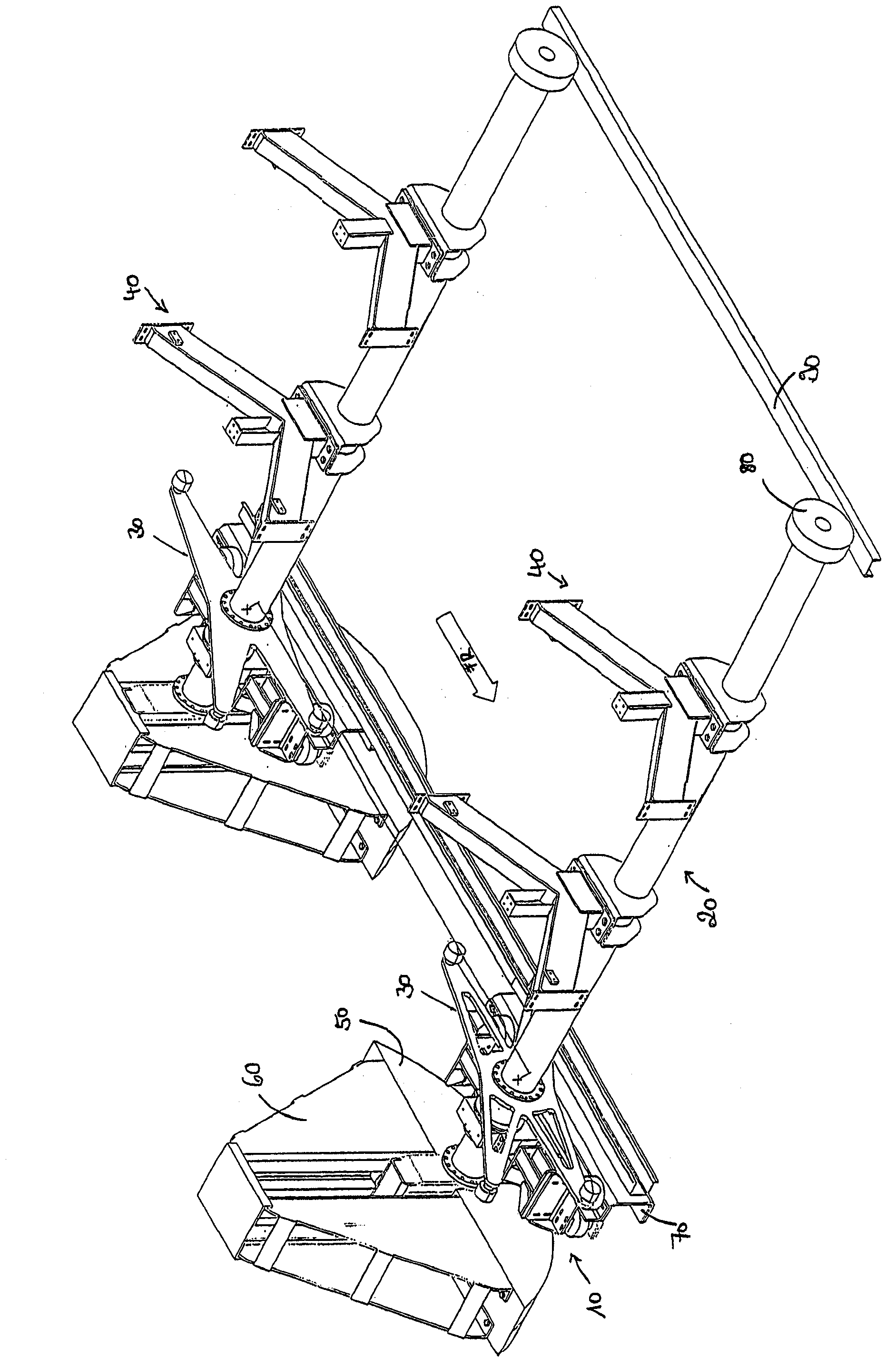

[0041] exist figure 1 A schematic general view of the apparatus of the present invention is depicted in .

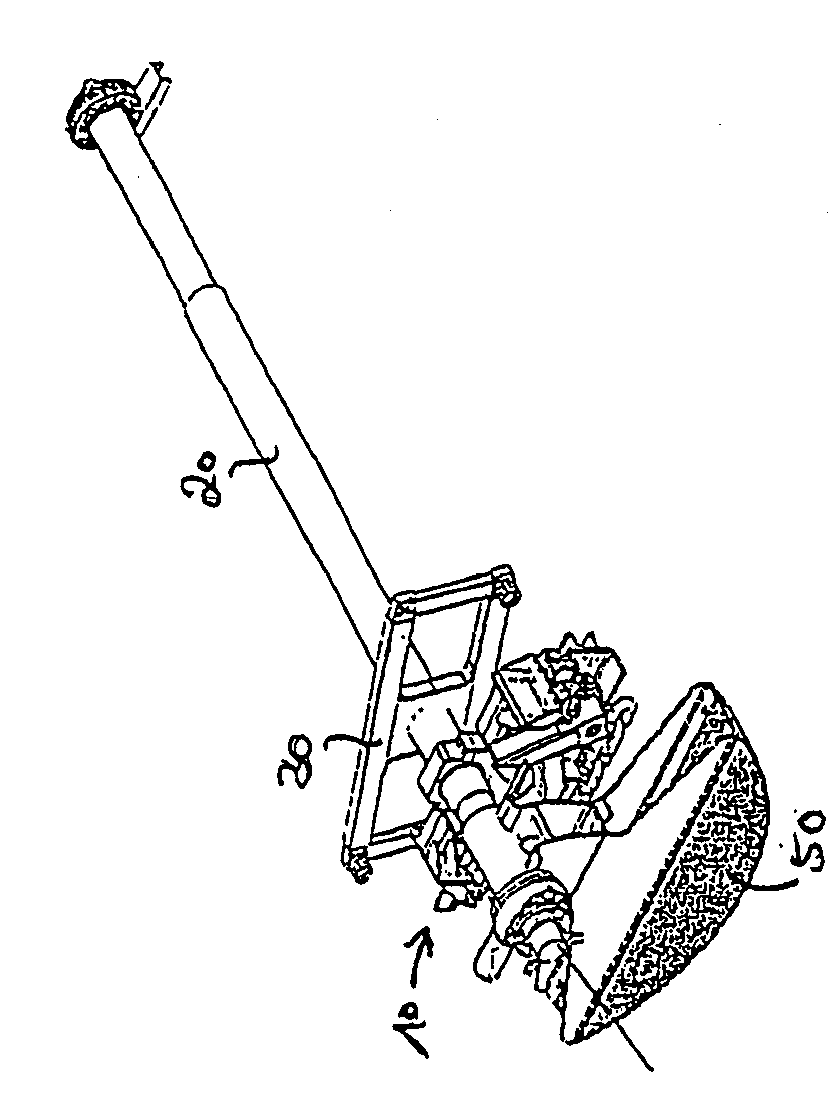

[0042] With this device, workpieces can be transported through a processing station. In particular, such a device can be used to guide body components through a dip in order to paint these components. For this purpose, the device has several workpiece holders, which are figure 1 Two of them are described in , and the tool holders are each formed by a transport carriage 10 and a pivot 20 as basic components.

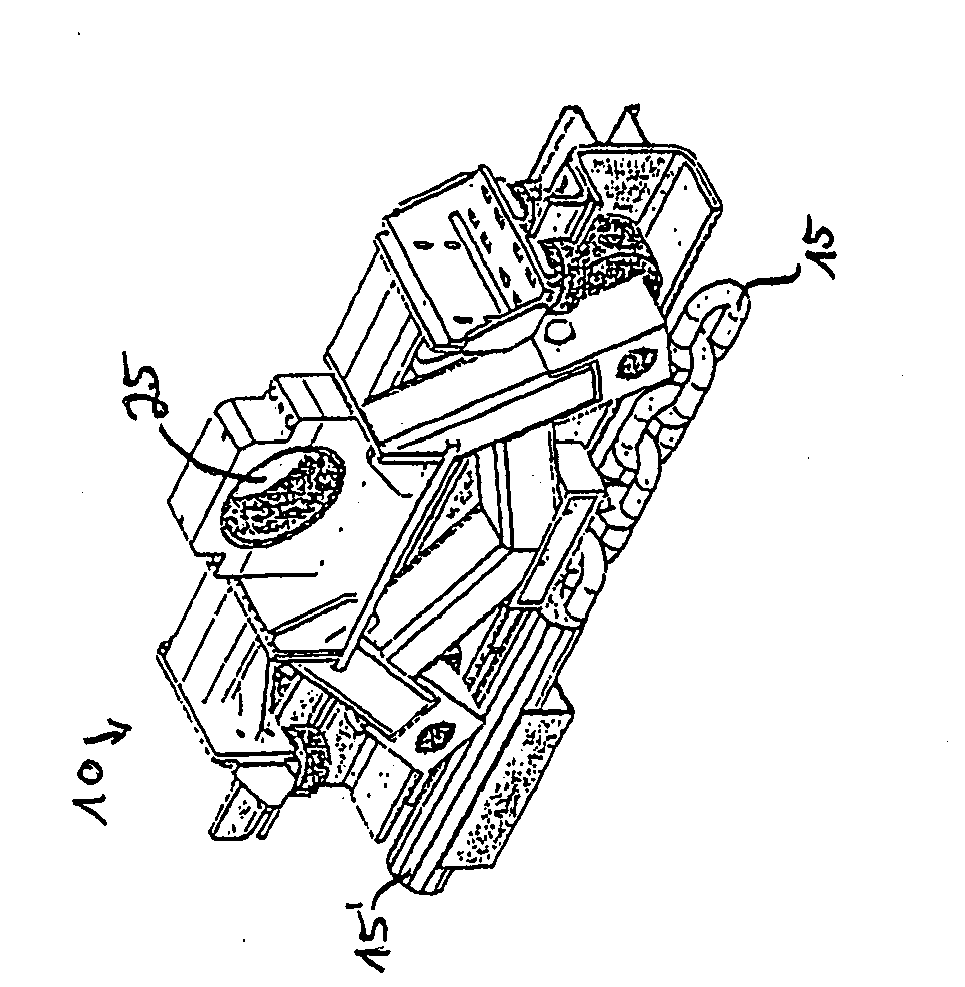

[0043] The shafts 20 themselves each have a bracket 40 on which the body components to be painted can be mounted directly or via a so-called slide. The shaft 20 is rotatably mounted on the transport carriage 10 and moves together with the transport carriage 10 along a guide rail 70 in a transport direction designated "FR". For this purpose, the transport carriage 10 is driven, for example, by means of a conveyor chain, a rope or a belt. Next to the guide rail 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com