Crank rocker weft insertion mechanism for rapier loom

A technology of rapier looms and crank rockers, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of limitation and improvement, and achieve the effect of low manufacturing cost, low manufacturing cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

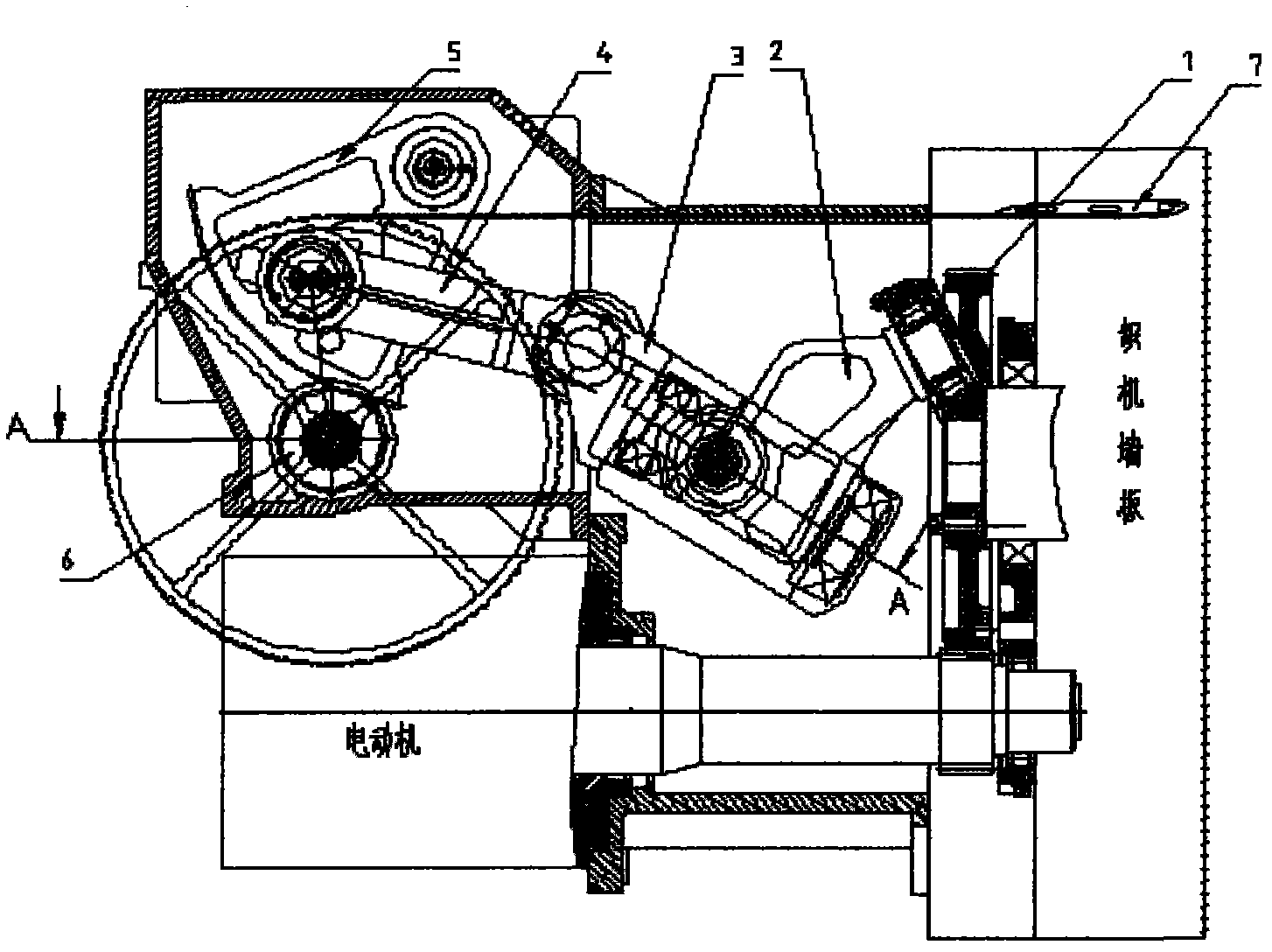

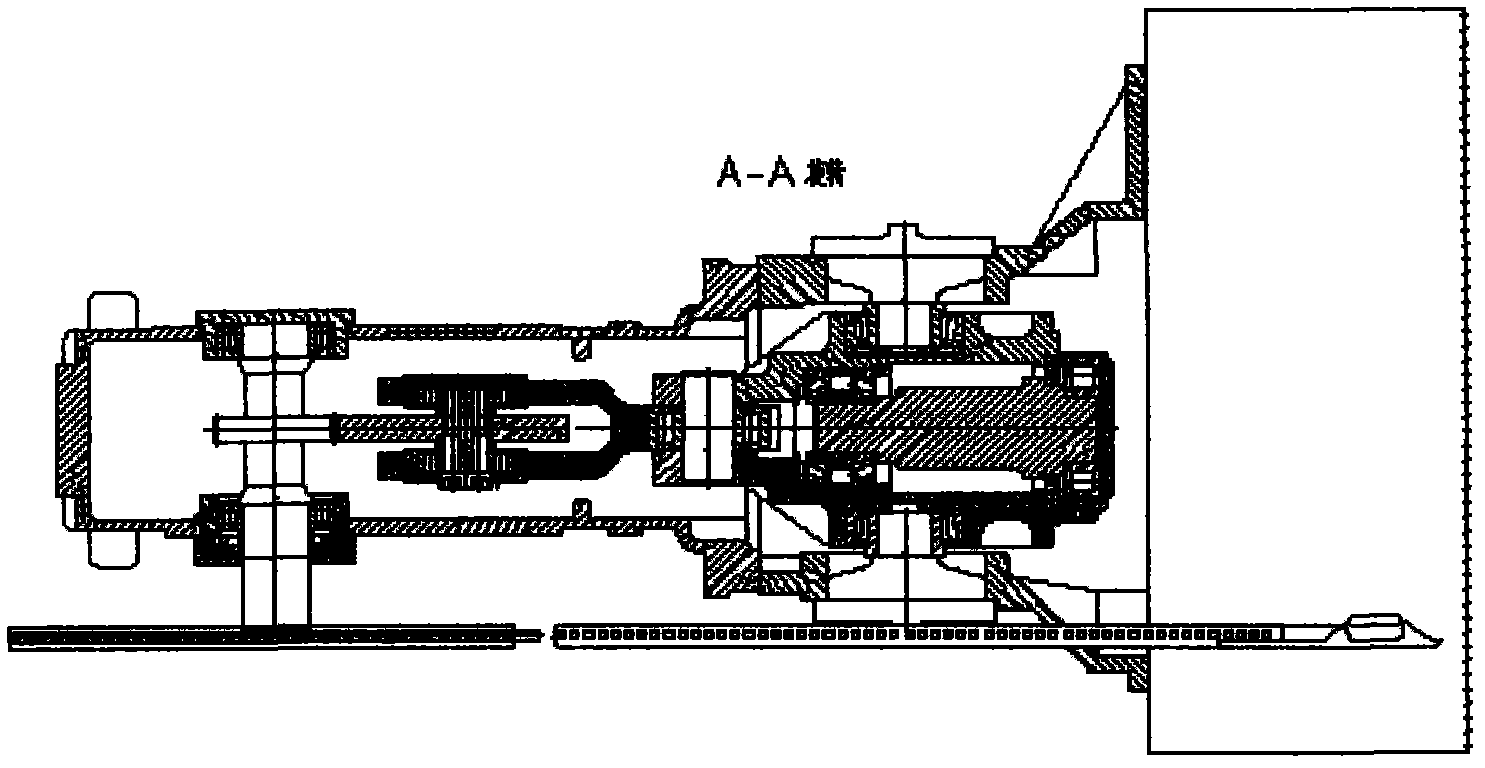

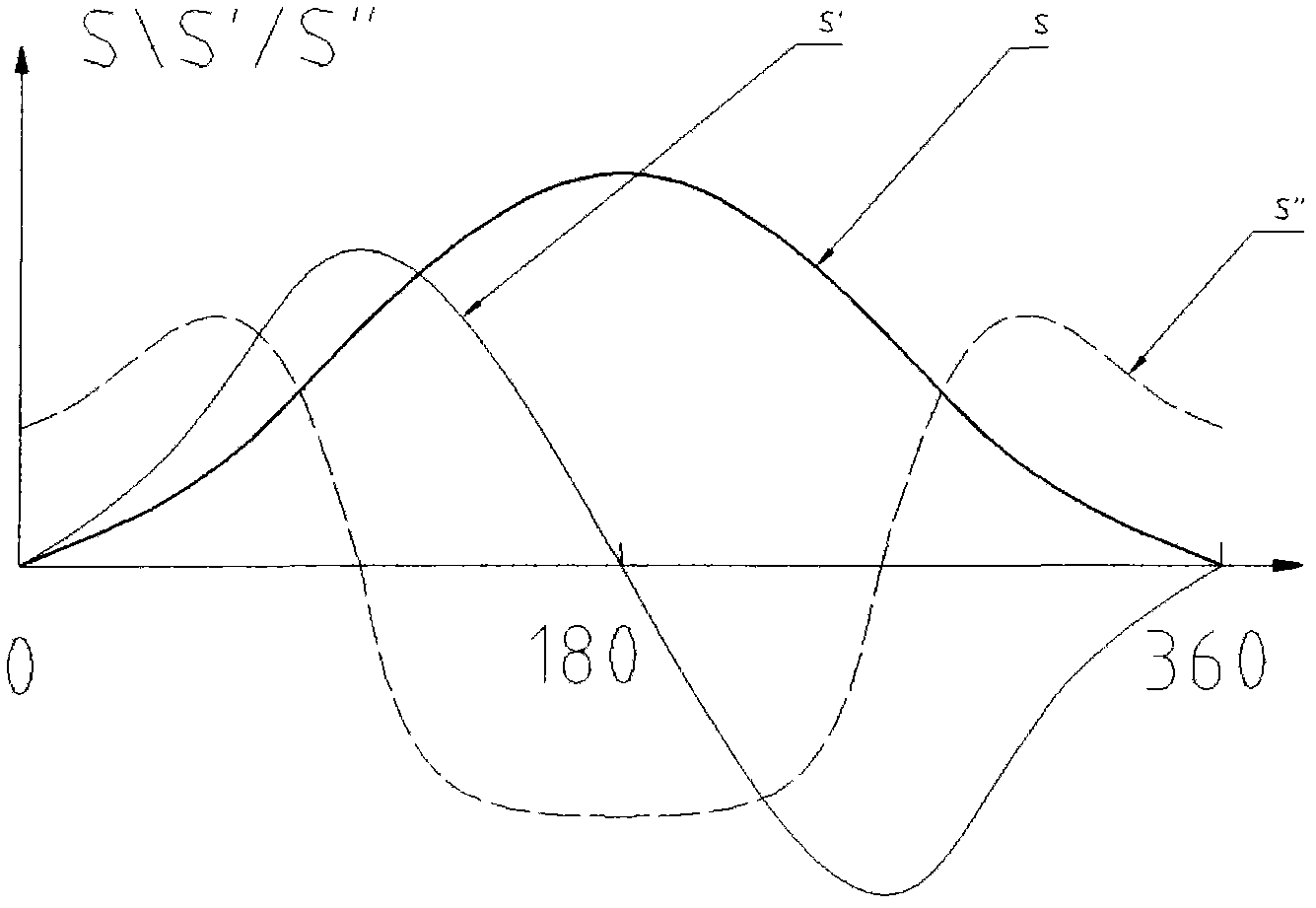

[0014] Such as Figure 1-3 As shown, a crank and rocker weft insertion mechanism of a flexible rapier loom is composed of a crank 1, a rocker 2, a large pendulum 3, a connecting rod 4, a sector gear 5, a dial shaft 6, a rapier belt and a rapier head 7 The crank is fixed on the main shaft, the crank is connected to the rocker, the rocker is connected to the pendulum, the connecting rod is connected to the pendulum and the sector gear, the dial shaft is meshed with the sector gear, and the dial shaft is connected to the sword belt and the sword head.

[0015] The specific working process of this kind of crank rocker weft insertion mechanism is: the crank 1 fixed on the main shaft rotates under the drive of the main shaft, drives the rocker 2 to move in space, the rocker moves to drive the pendulum 3 to swing, and the connecting rod 4 Connected with the large pendulum and the sector gear 5, the connecting rod 4 transmits the swing of the large pendulum 3 to the sector gear 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com