Conductive composite vacuum soft soil reinforcing prepressing method

A soft soil and preloading technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of long construction period, high cost, tearing vacuum membrane, etc., and achieve the effect of reducing construction cost and saving treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

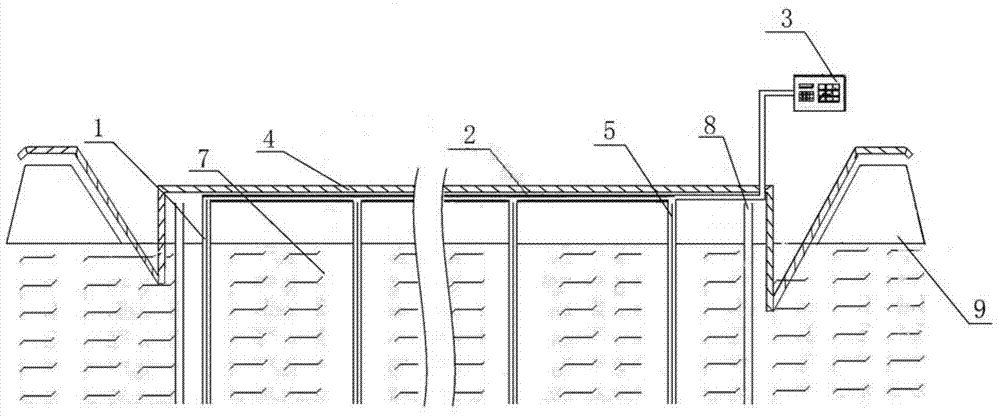

[0027] Such as figure 1 As shown, a freshly filled silt has an extremely soft site with almost zero initial bearing capacity. Since the site is freshly filled with silt, its initial bearing capacity is almost zero. Therefore, foundation treatment is required to increase its bearing capacity to 60Kpa-90Kpa for subsequent construction.

[0028] The specific method is as follows: firstly, the plastic drainage board 1 is artificially inserted on the treated soil 7, the depth of the plastic drainage board 1 inserted into the treated soil 7 is 2 meters to 27 meters, and the adjacent plastic drainage boards The distance between 1 is 0.3m to 4.0m. Metal wires 5 are provided inside the plastic drainage board 1. The metal wires 5 in the plastic drainage board 1 are connected to the electrodes of the pulse current, and the adjacent metal wires 5 are connected to electrodes of different polarities. Pulse current electrode connection, specifically set as: the metal wire 5 of the first ro...

Embodiment 2

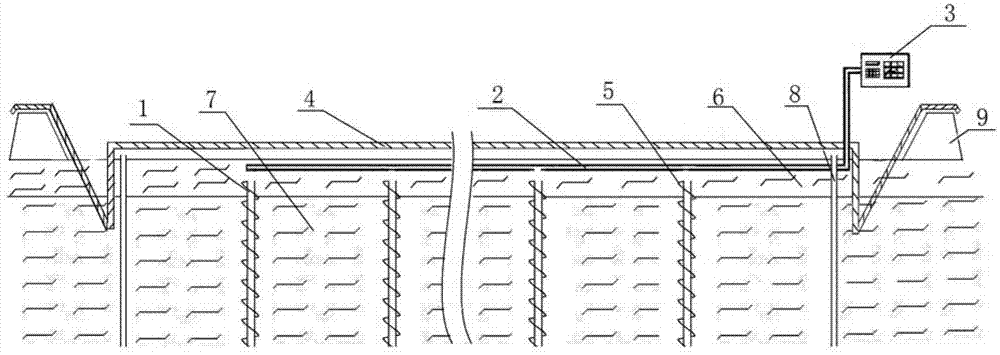

[0032] Such as figure 2 As shown, a certain construction site has been measured, and the initial bearing capacity of the surface layer of 0-4 meters is about 20KPa, which is a very soft foundation, and high-vacuum compaction equipment cannot enter the site for construction. According to the high-vacuum densification equipment entering the construction site, the surface bearing capacity requirement is 60Kpa ~ 70Kpa, so as to carry out subsequent construction.

[0033] The specific method is as follows: firstly, the plastic drainage board 1 is artificially inserted on the treated soil 7, the depth of the plastic drainage board 1 inserted into the treated soil 7 is 18 meters to 44 meters, and the adjacent plastic drainage boards The distance between 1 is 1.7 meters to 3.5 meters. The metal wire 5 is wound on the outside of the plastic drainage board 1. The metal wire 5 is connected to the electrode of the pulse current, and the adjacent metal wire 5 is connected to the pulse cur...

Embodiment 3

[0037] Such as figure 1As shown, a certain construction site has been measured, and the initial bearing capacity of the surface layer of 0-3 meters is about 10KPa, which is a very soft foundation, and high-vacuum compaction equipment cannot enter the site for construction. According to the high-vacuum densification equipment entering the construction site, the surface bearing capacity requirement is 60Kpa ~ 70Kpa, so as to carry out subsequent construction.

[0038] The specific method is as follows: firstly, the plastic drainage board 1 is artificially inserted on the treated soil 7, the depth of the plastic drainage board 1 inserted into the treated soil 7 is 27 meters to 50 meters, and the adjacent plastic drainage boards The distance between 1 is 1.1 meters to 5.0 meters. The metal wire 5 is arranged inside the plastic drainage board 1. The metal wire 5 is connected to the electrode of the pulse current, and the adjacent metal wire 5 is connected to the pulse current elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com