Correction method for storage tank foundation

A storage tank foundation and deviation correction technology is applied in the field of storage tank foundation deviation correction, which can solve the problems of high cost, long deviation correction processing process, and inability to accurately level the storage tank foundation, etc., to expand the application scope, low cost, reduce processing costs and The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail with reference to the accompanying drawings, but the scope of protection of the present invention is not limited to the following embodiments, that is, all simple equivalent changes and modifications made based on the scope of the patent application of the present invention and the contents of the description shall still belong to the patent of the present invention. Within the scope of coverage.

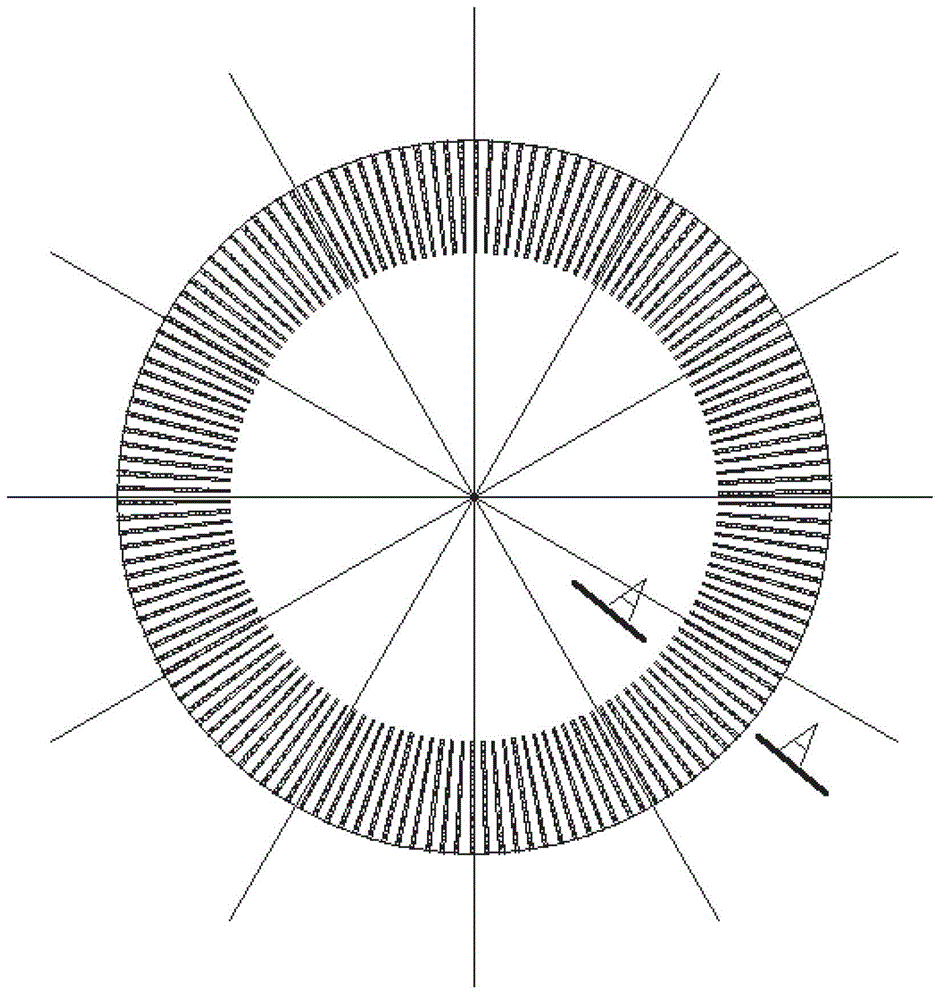

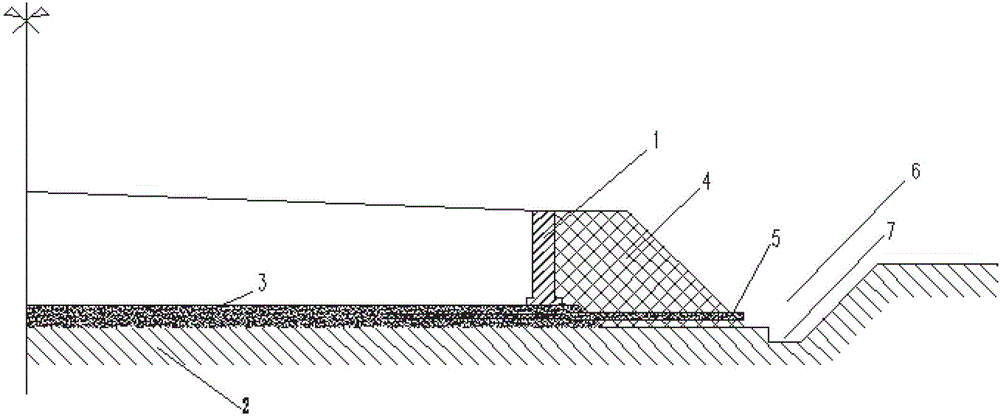

[0029] Such as figure 1 , 2 As shown, a method for correcting the foundation of a storage tank includes the following steps:

[0030] ① Set a circular sand cushion 3 on a foundation soil 2, which can at least completely place the annular storage tank foundation 1 to be corrected on it;

[0031] ② A number of annular shaped sand bag layers 5 are arranged on the sand cushion layer. The shaped sand bag layer is formed by arranging several sand bags filled with sand in sequence. The gaps between adjacent sand bags are filled with sand, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com