Three-channel combustion gas turbine liquid fuel metering method and device thereof

A technology of gas turbine and liquid fuel, which is applied in the direction of turbine/propulsion fuel delivery system, fuel control of turbine/propulsion device, charging system, etc., and can solve the problem of low reliability of fuel metering device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

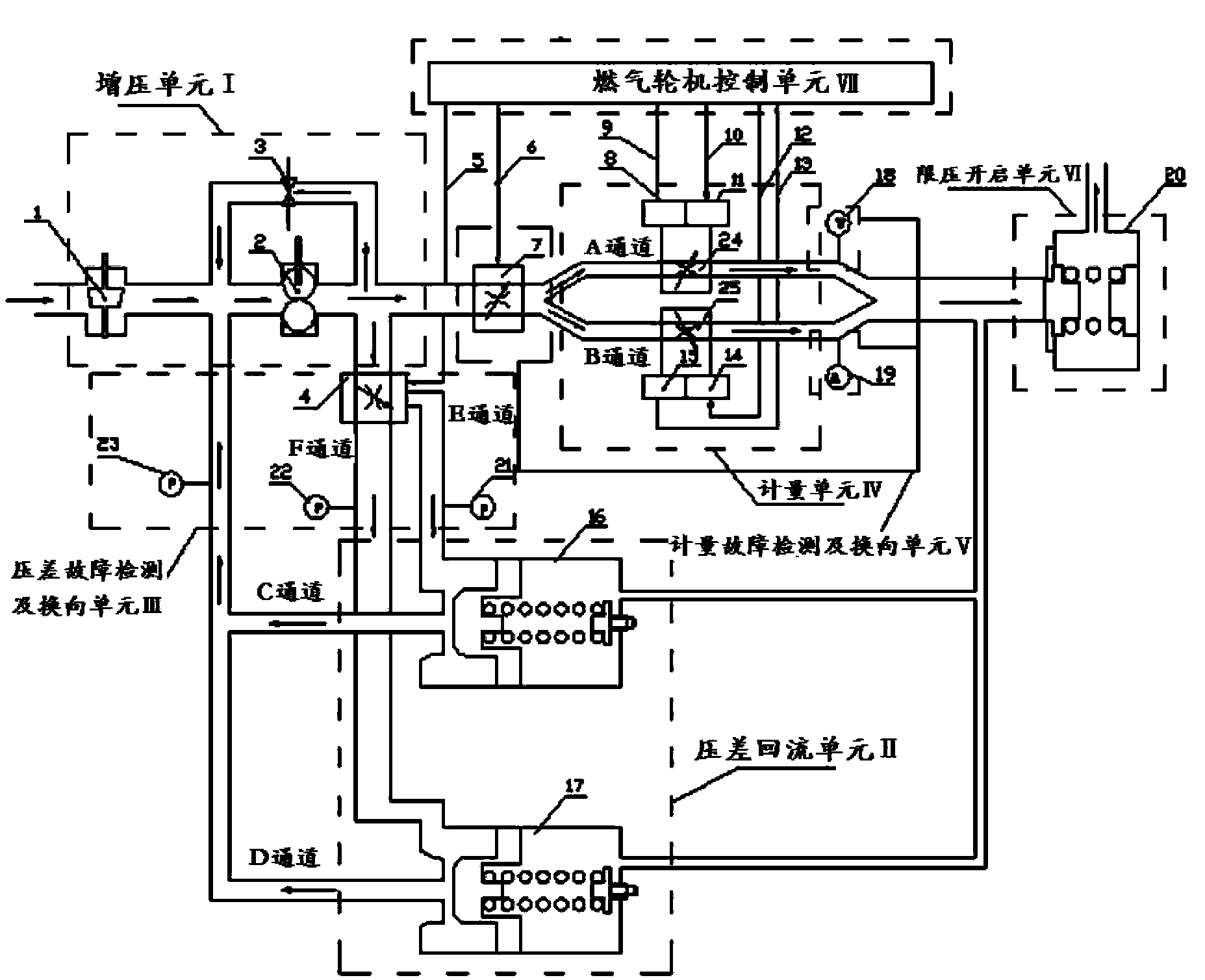

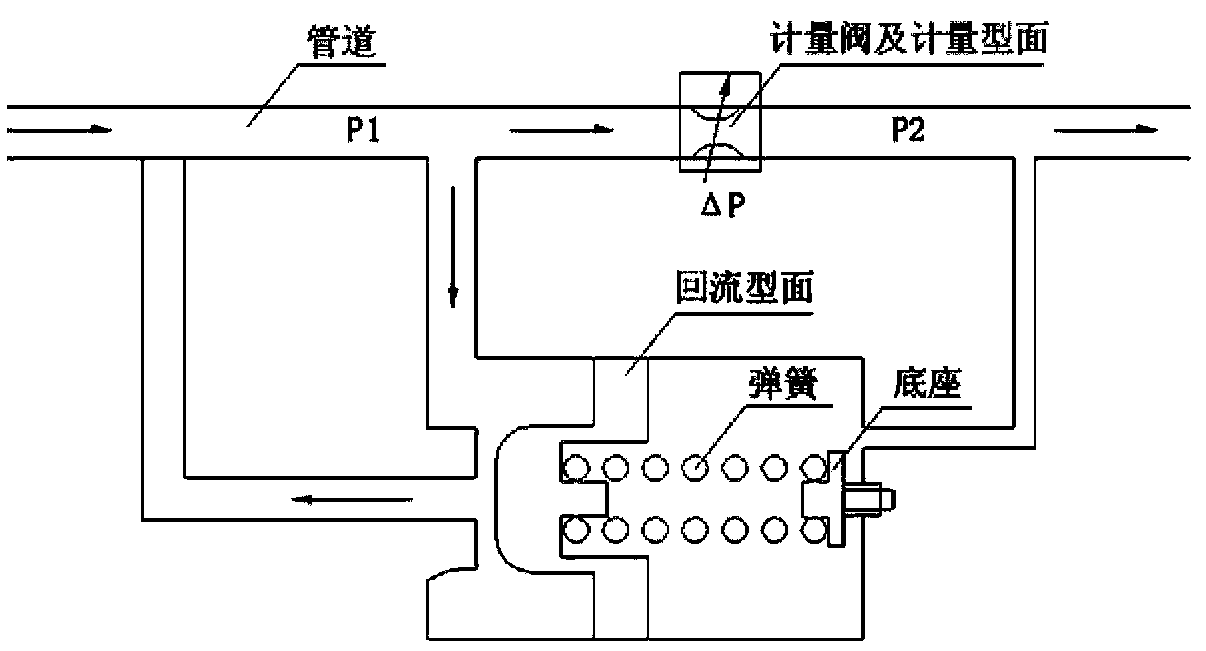

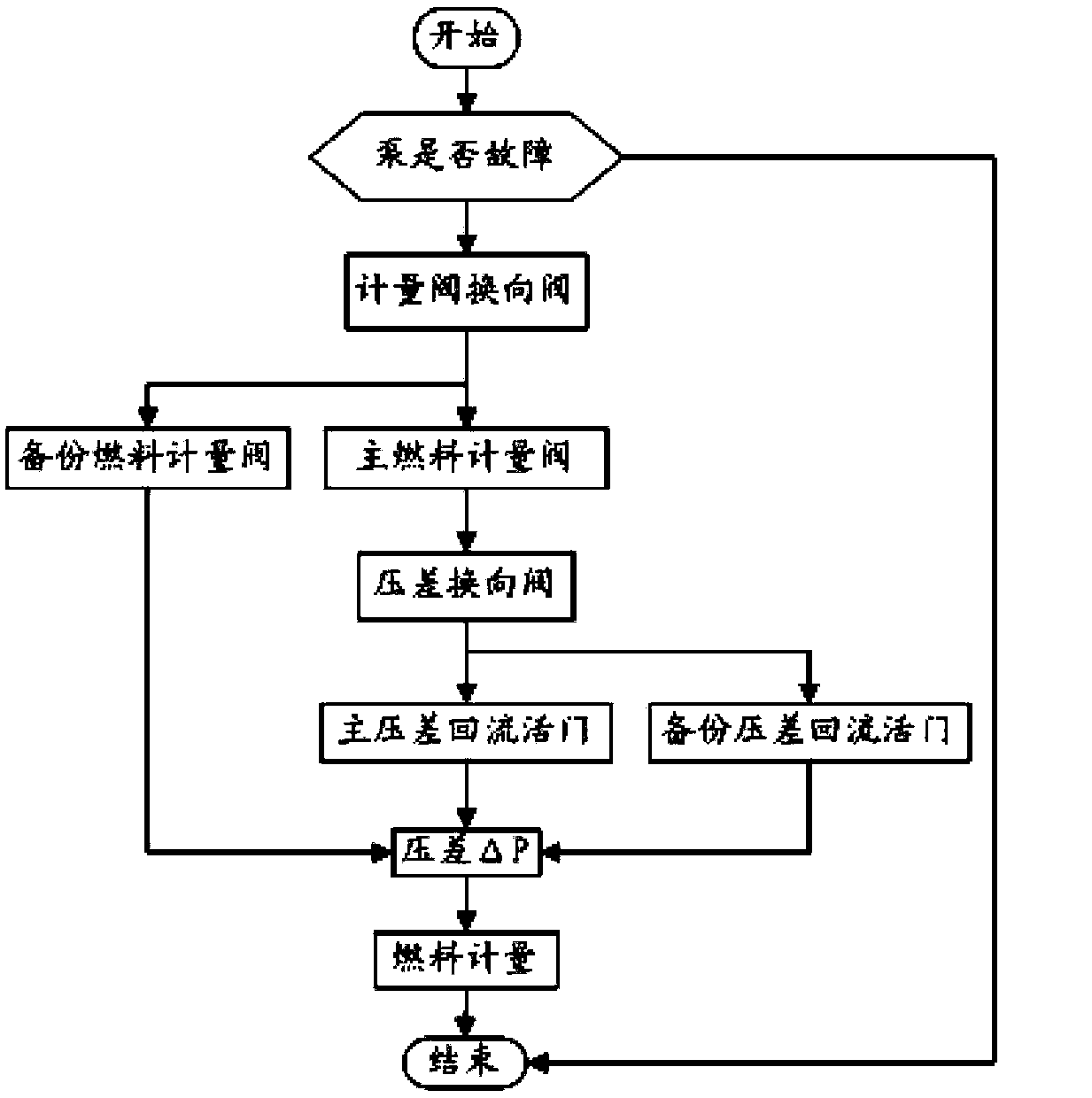

[0046] The connection method is as Figure 1-2 As shown, the control principle is as image 3 shown. In this implementation method, the main metering valve and the main differential pressure return valve work. The implementation process includes centrifugal pump 1, gear pump 2, safety valve 3, differential pressure return valve reversing valve 4, differential pressure return reversing control signal 5, metering valve reversing control signal 6, metering reversing valve 7, main fuel Metering displacement sensor 8, main fuel metering displacement detection signal 9, main fuel metering servo motor control signal 10, main fuel metering servo motor 11, main differential pressure return valve 16, A channel flow meter 18, pressure limiting valve 20, E channel pressure The sensor 21, the return path pressure sensor 23 and the main metering valve 24 work. It can realize fuel metering A channel and differential pressure return E channel.

Embodiment 2

[0048] The connection method is as Figure 1-2 As shown, the control principle is as image 3 shown. In this implementation method, the main metering valve and the backup differential pressure return valve work. The implementation process includes centrifugal pump 1, gear pump 2, safety valve 3, differential pressure return valve reversing valve 4, differential pressure return reversing control signal 5, metering valve reversing control signal 6, metering reversing valve 7, main fuel Metering displacement sensor 8, main fuel metering displacement detection signal 9, main fuel metering servo motor control signal 10, main fuel metering servo motor 11, backup differential pressure return valve 17, A channel flow meter 18, pressure limiting valve 20, F channel pressure The sensor 22, the return path pressure sensor 23 and the main metering valve 24 work. It can realize fuel metering A channel and differential pressure return F channel.

Embodiment 3

[0050] The connection method is as Figure 1-2 As shown, the control principle is as image 3 shown. In this implementation method, the backup metering valve and the main differential pressure return valve work. The implementation process includes centrifugal pump 1, gear pump 2, safety valve 3, differential pressure return valve reversing valve 4, differential pressure return reversing control signal 5, metering valve reversing control signal 6, metering reversing valve 7, backup fuel Metering servo motor control signal 12, backup fuel metering displacement detection signal 13, backup fuel metering servo motor 14, backup fuel metering displacement sensor (LVDT) 15, main differential pressure return valve 16, B channel flowmeter 19, pressure limiting valve 20, The pressure sensor 21 of the E channel, the pressure sensor 23 of the return channel and the backup metering valve 25 work to realize the fuel metering of the B channel and the differential pressure backflow of the E ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com