Sealing structure of explosion proof purification light fitting

A technology for sealing structures and lamps, which is applied in the direction of air-proof/waterproof devices, lighting devices, and parts of lighting devices, etc. It can solve the problems of poor purification effect of lamps, influence on dust-proof conditions, and influence on purification effects, etc., and achieve material reduction consumption, improve heat dissipation, and save material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

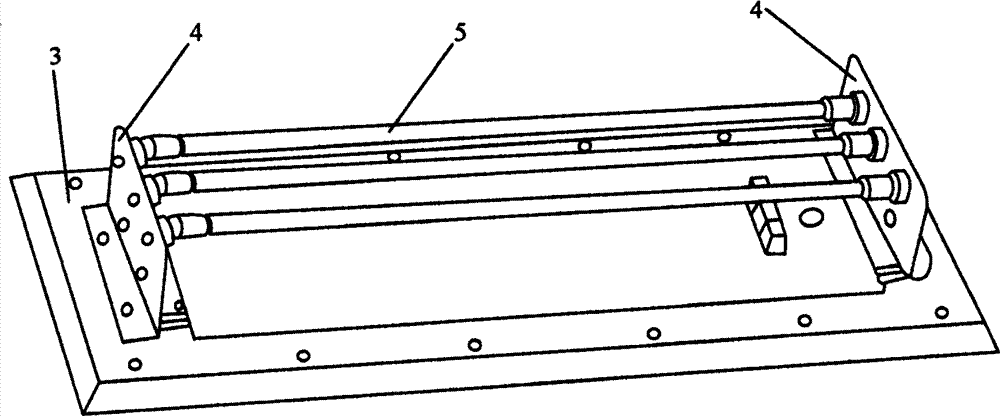

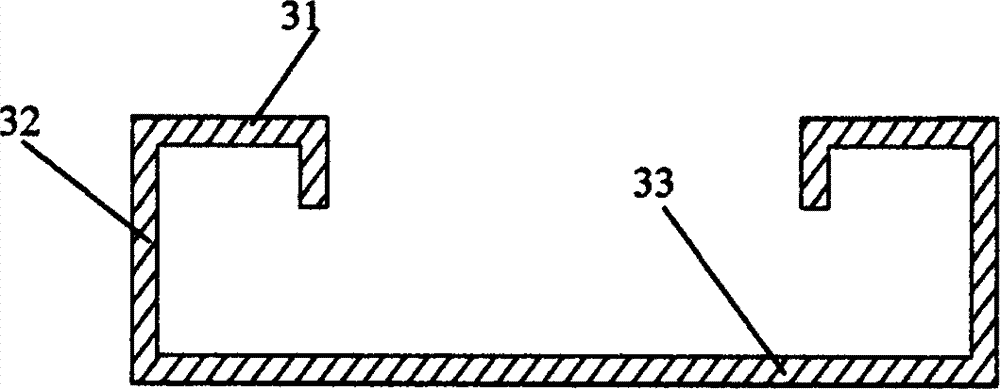

[0045] Such as Figure 5 , the bottom wall 33 is a hollow frame on the plane, the top wall 31 is a concave platform 311 formed by the middle part being recessed toward the direction of the bottom wall 33, and the lamp pin 4 is arranged on the concave platform 311 through the lamp holder. There is a gap between the concave platform 311 and the side wall 32 to form a channel.

[0046] Such as Figure 6 , The lower part of the sealing screw 13 is located in the gap between the concave platform 311 and the side wall 32, so the sealing screw is isolated from the explosion-proof chamber to enhance safety.

[0047]In addition, the trench can significantly improve the heat dissipation of the entire lamp. For integral molding, convenient installation and aesthetics, the bottom of the recessed platform 311 is usually flat and flush with the bottom wall 33 .

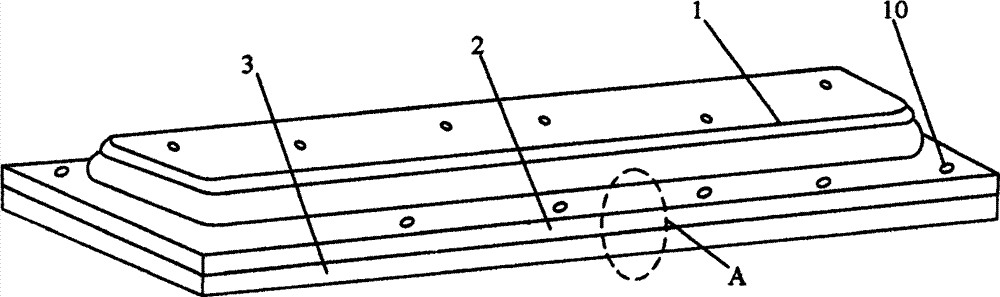

[0048] The fixation of the lampshade 1 in this embodiment still uses the existing mode, the lamp cover 2 and the pressure plat...

no. 2 example

[0051] Such as Figure 7 , an explosion-proof purification lamp sealing structure, including detachably connected lampshade 1, lamp cover 2, base 3 in sequence; base 3 includes a top wall 31 connected to the lamp cover 2, a bottom wall 33 connected to the ceiling and a connecting top wall 31 With the four side walls 32 of the bottom wall 33 , the bottom wall 33 is a hollow frame on the plane, and the middle part of the top wall 31 is recessed toward the bottom wall 33 to form a concave platform 311 , and there is a gap between the concave platform 311 and the side wall 32 .

[0052] The lower part of the lampshade 1 is connected with the lamp cover 2 through fastening screws 12 , and a sealing ring 11 is arranged between the lower part of the lampshade 1 and the top end of the top wall 31 . The width of the sealing ring 11 can cover the bottom surface of the lower part of the lampshade 1 .

[0053] Figure 7 The end of the lower part of the lampshade 1 shown is bent upwards,...

no. 3 example

[0058] Such as Figure 8 The other parts of this embodiment are the same as those of the second embodiment, the difference is that there are two convex strips 101 at the bottom of the lower part of the lampshade 1, the fastening screw 12 is arranged between the two convex strips 101, and the upper part of the sealing ring 11 is clamped Between the two convex strips 101.

[0059] The width of the lower section of the sealing ring 11 is greater than that of the upper section, shoulders are formed on both sides of the middle section of the section, and the two convex lines 101 on the lower part of the lampshade 1 are respectively supported on the shoulders on both sides. The bottom of the section of the sealing ring 11 is arc-shaped.

[0060] In this embodiment, the cooperation between the convex strip 101 and the seal ring 11 can compress the seal ring 11 without displacement. Especially the bottom 11 of the sealing ring is arc-shaped, as long as the sealing screws are tighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com