Simple depth touch gauge

A touch gauge and depth technology, applied in the field of touch gauges, can solve the problems of judgment errors and low detection accuracy, and achieve the effects of convenient operation, high detection efficiency and reduction of judgment errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

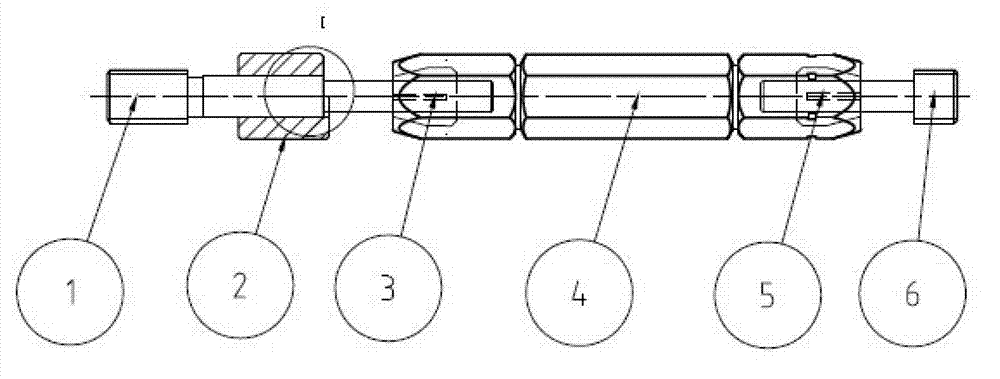

[0015] Such as figure 1 , figure 2 As shown, the present invention is mainly composed of a measuring body threaded end 1, a measuring body 2, a first tensioning sleeve 3, a three-color handle 4, a second tensioning sleeve 5 and a measuring body threaded end 6.

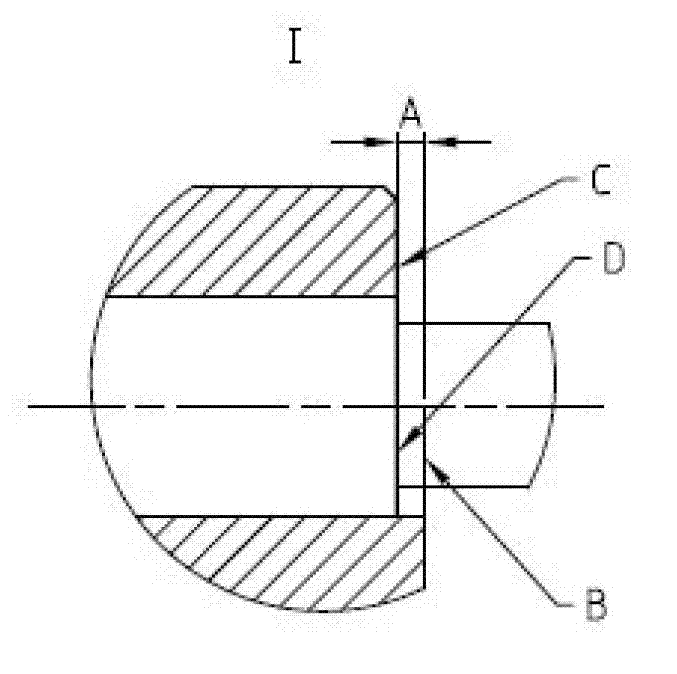

[0016] The measuring body 2 is slidingly connected with the threaded end 1 of the measuring body, and can slide axially and rotate radially along the threaded end 1 of the measuring body. end, the thread stop end 6 of the measuring body is fixed on the red end of the three-color handle 4 through the second tensioning sleeve 5, B is the lower semicircular surface of the measuring body, C is the upper semicircular surface of the measuring body, and A is the axial direction between B and C. distance, and the value is equal to the tolerance value of the threaded hole depth parameter, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com