Automatic envelope leak detection during tire curing

A technology for tires and cured films, applied in tires, household appliances, other household appliances, etc., can solve problems such as the inability to reduce manifold pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

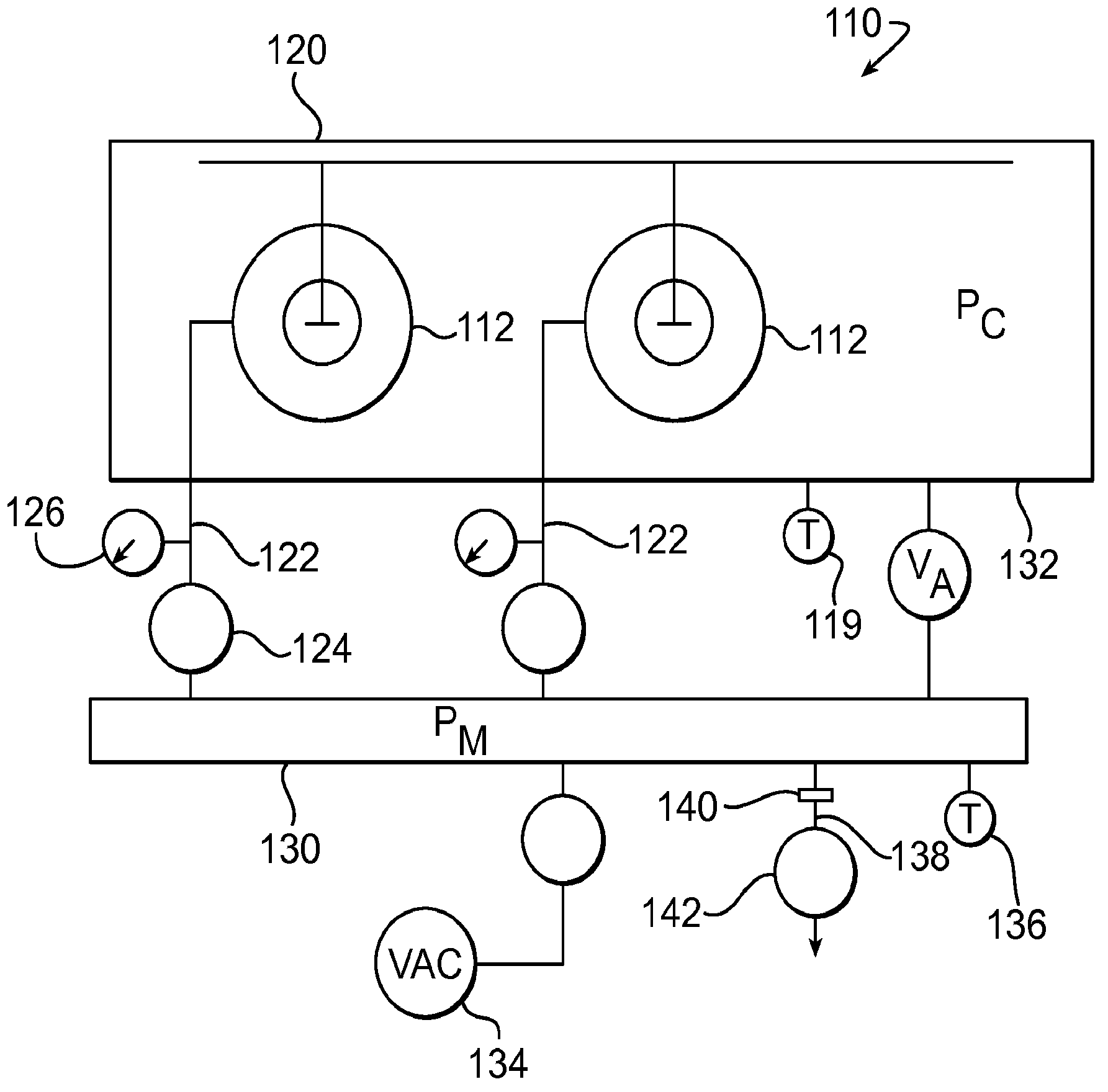

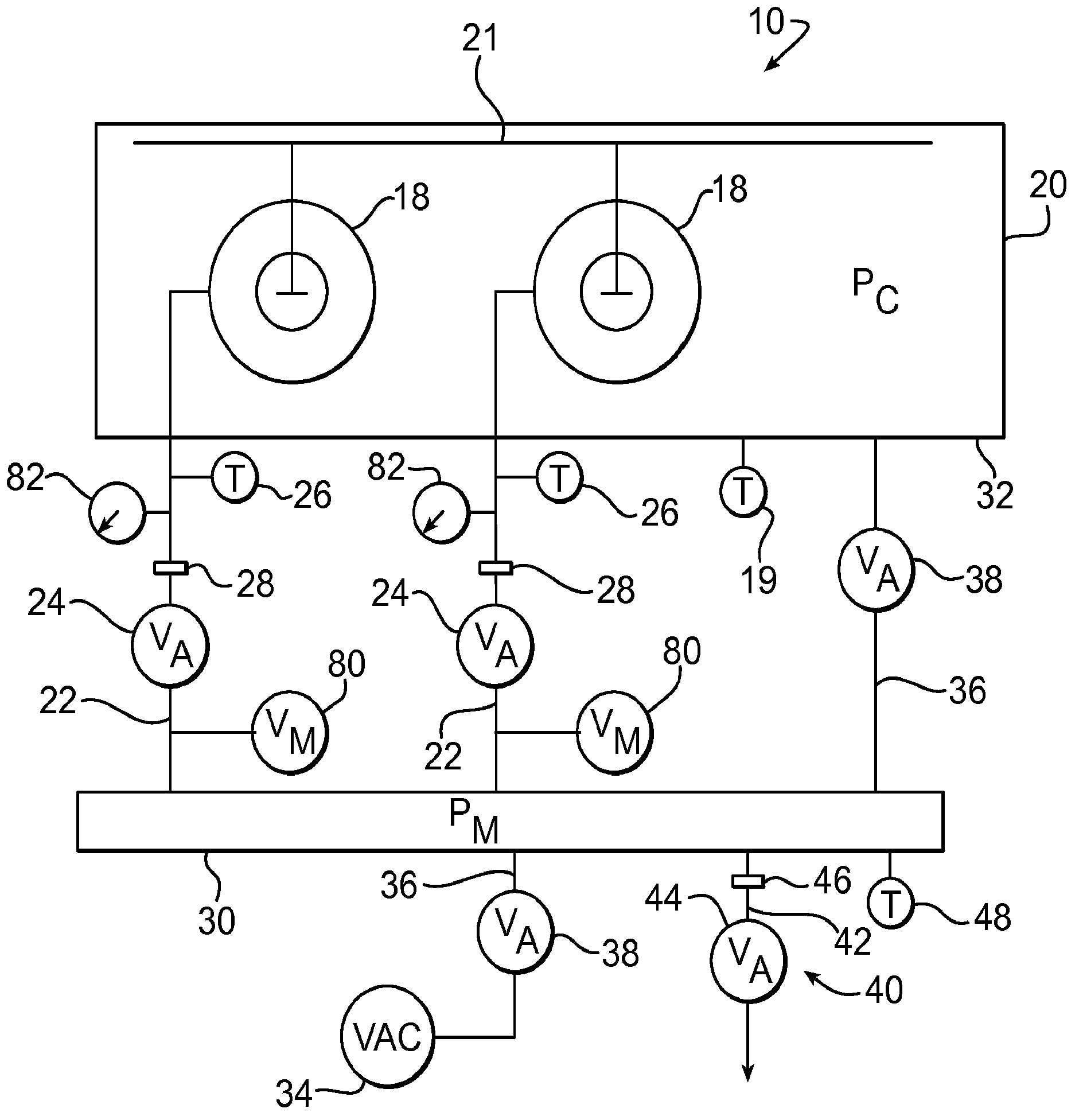

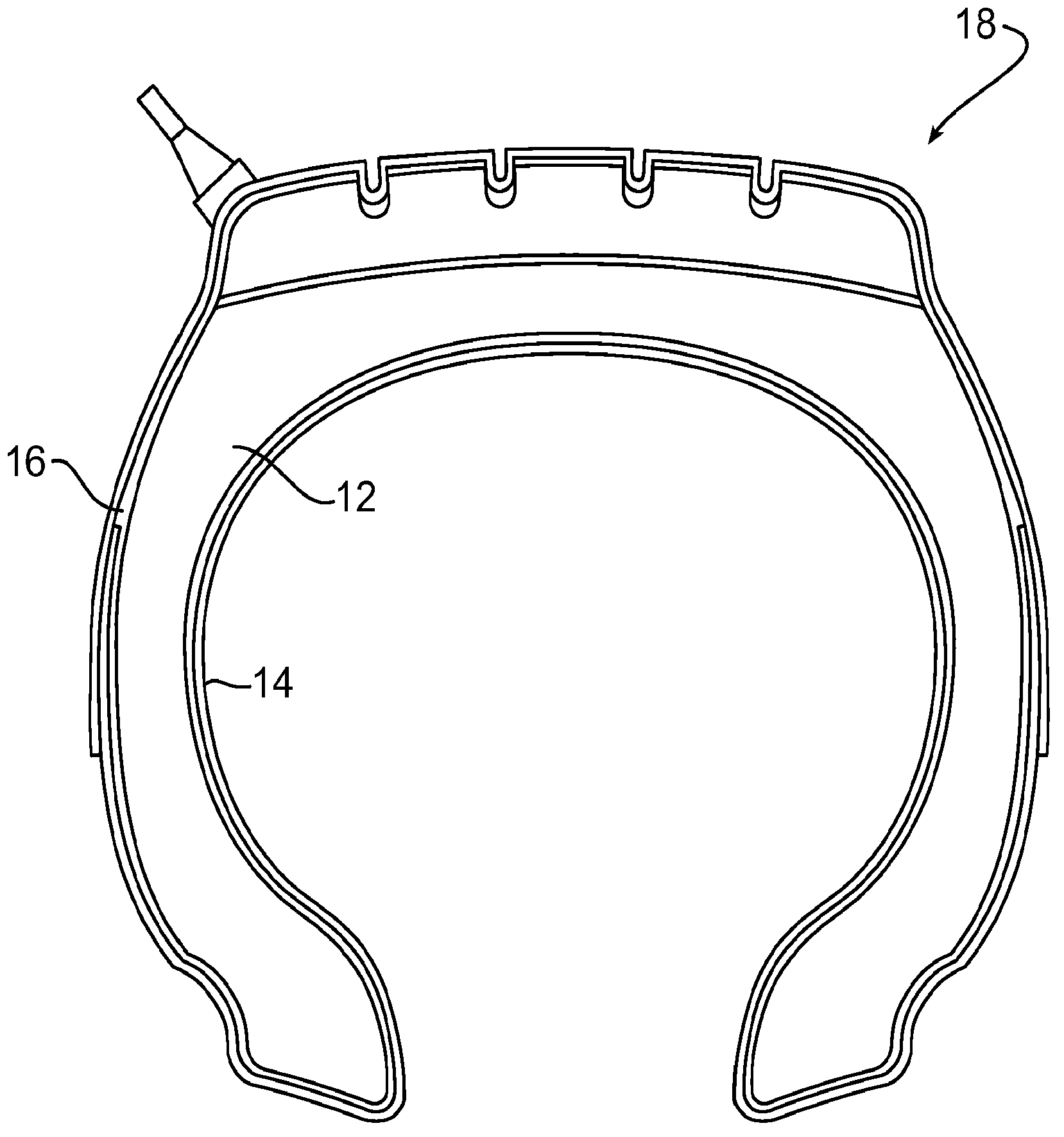

[0018] Certain embodiments of the present invention provide methods and apparatus for curing retreaded tires, including methods and apparatus for detecting fluid leakage in a tire-membrane assembly during a curing operation of a retreaded tire. Curing operations include preparations that take place prior to initiating the curing process, which involves increasing the heat and pressure within the curing chamber to cure the tread to the tire carcass.

[0019]Particular embodiments of such methods may include the step of placing a plurality of tire-membrane assemblies within a tire curing chamber of a tire curing system, each tire-membrane assembly comprising a retreaded tire and a flexible curing membrane surrounding the At least a portion of the retreaded tire is mounted to form a sealed fluid chamber between the membrane and the tire. Before the curing process begins, a plurality of retreaded tires are loaded into the curing chamber of the curing system for curing. A flexible...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com