Transfusion device having automatic bottle change and safety protection functions

A safety protection and infusion device technology, applied in the field of medical devices, can solve problems such as air entry, venous blood return to veins, and patient health threats, and achieve the effects of reducing workload, improving safety, and preventing venous blood backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

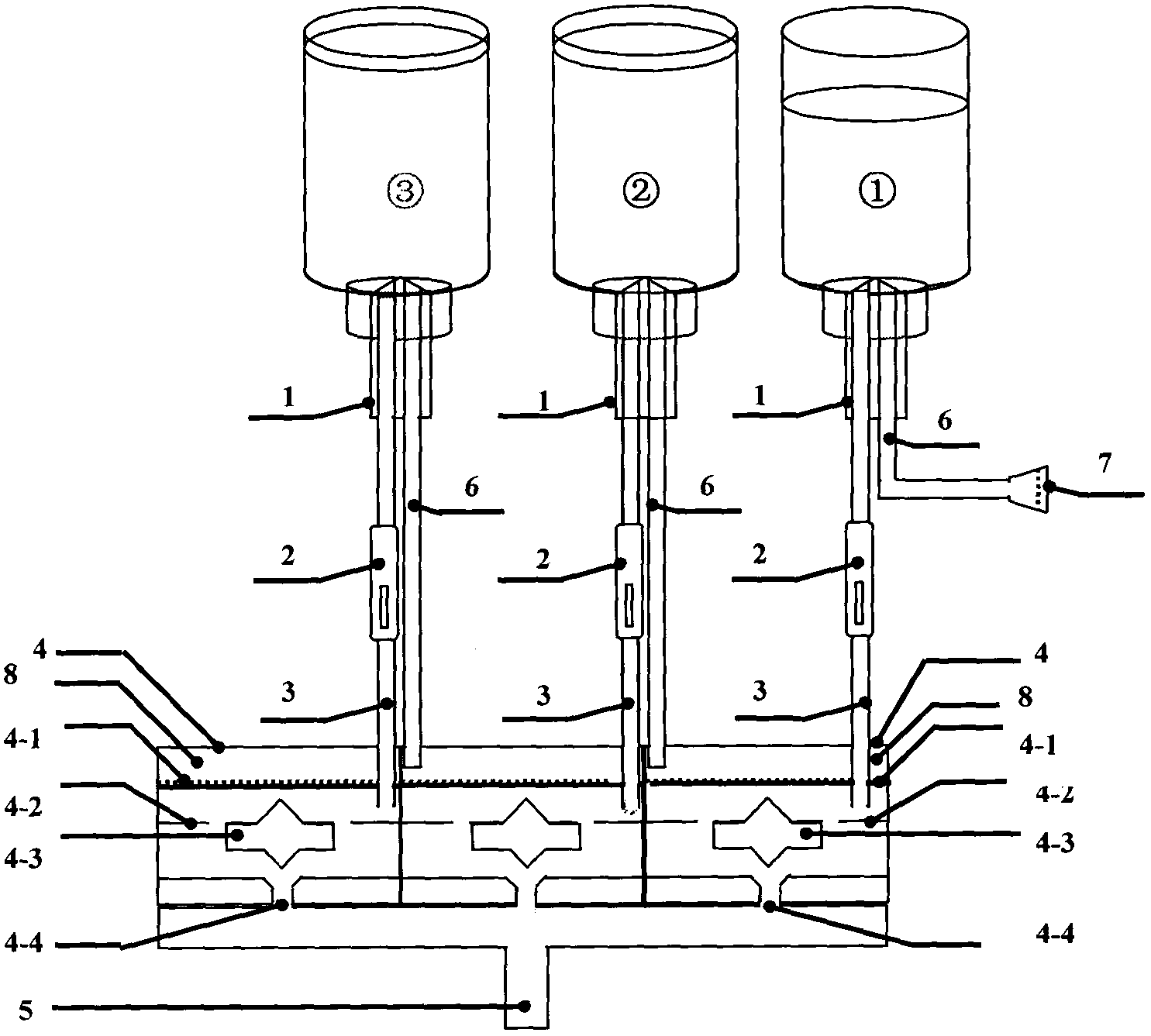

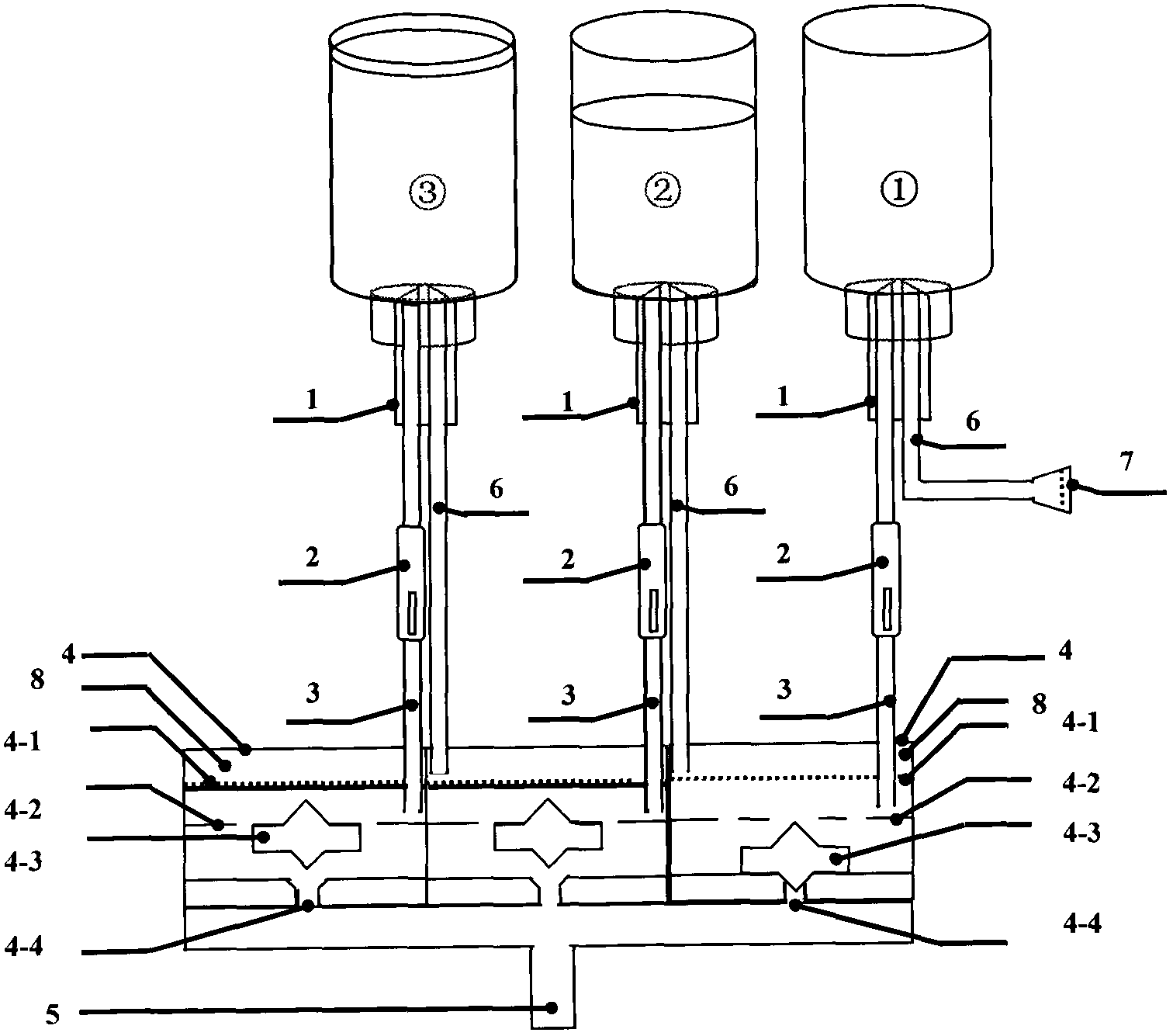

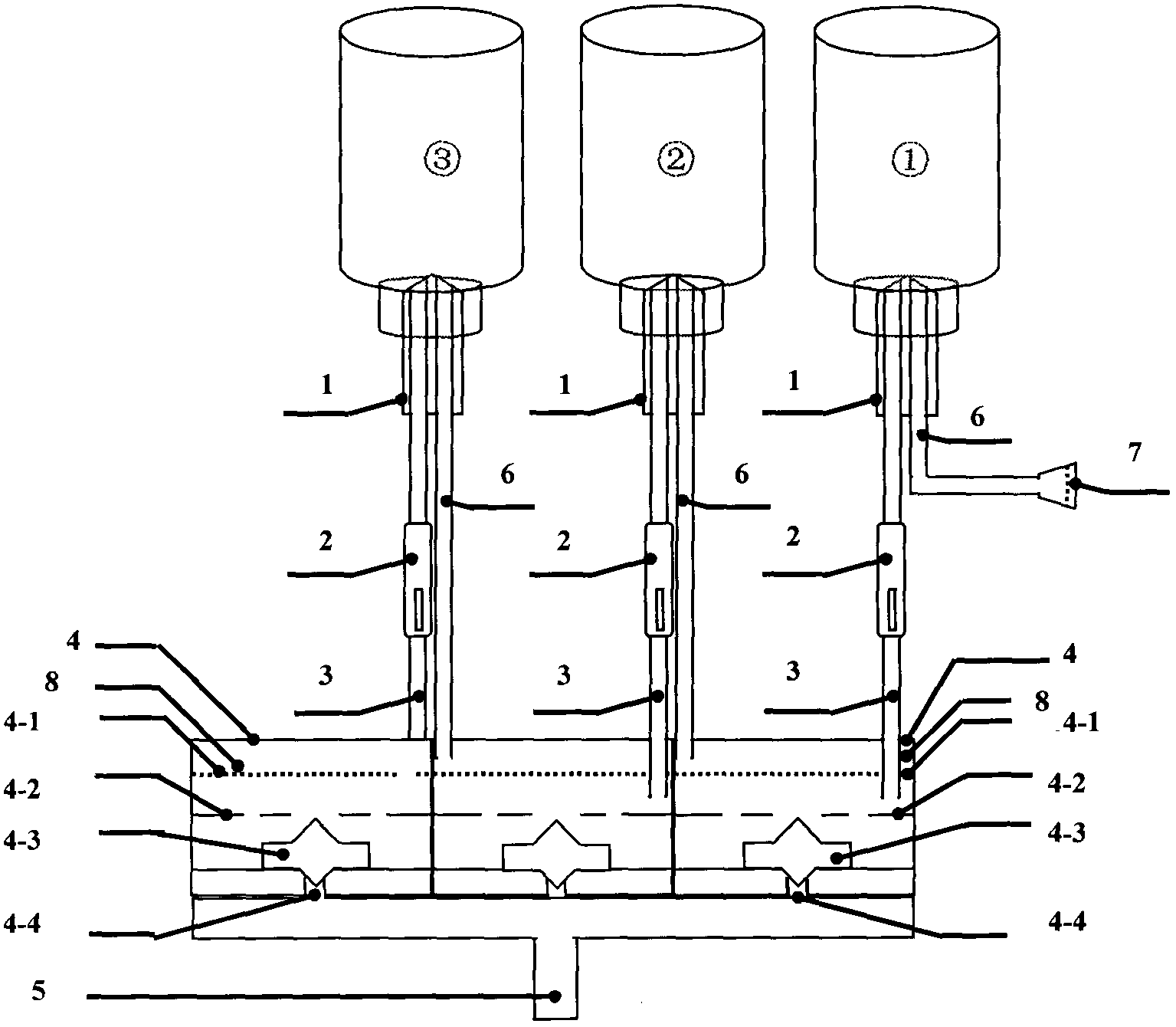

[0014] like figure 1 shown:

[0015] The stopper piercer 1 is inserted into the infusion bottle, the stopper piercer 1 is connected to the dripping speed regulator 2, the dripping speed regulator 2 is connected to the liquid passage 3, and the output port of the liquid passage 3 is below the liquid stop film 4-1 in the protection cavity 4 , above the baffle 4-2; the baffle 4-2 is fixedly connected in the protection cavity 4, the baffle 4-2 is provided with a liquid leakage hole 4-2-1, and the floating block 4-3 has medicinal liquid in the protection cavity 4 When there is no liquid medicine in the protection cavity 4, the floating block 4-3 falls back to block the outlet 4-4, and the floating block 4-3 has a protruding tip or conical structure above and below the middle. The upper tip is aimed at the leakage hole 4-2-1 on the baffle plate 4-2, the lower tip is aimed at the outlet 4-4, the bottom end of the protection chamber 4 is provided with an infusion pipeline 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com