Intermittent extrusion coating method, extrusion coating head and extrusion coating machine

A technology of extrusion coating and extrusion head, which is applied to the device and coating of the surface coating liquid to achieve the effect of solving tailing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

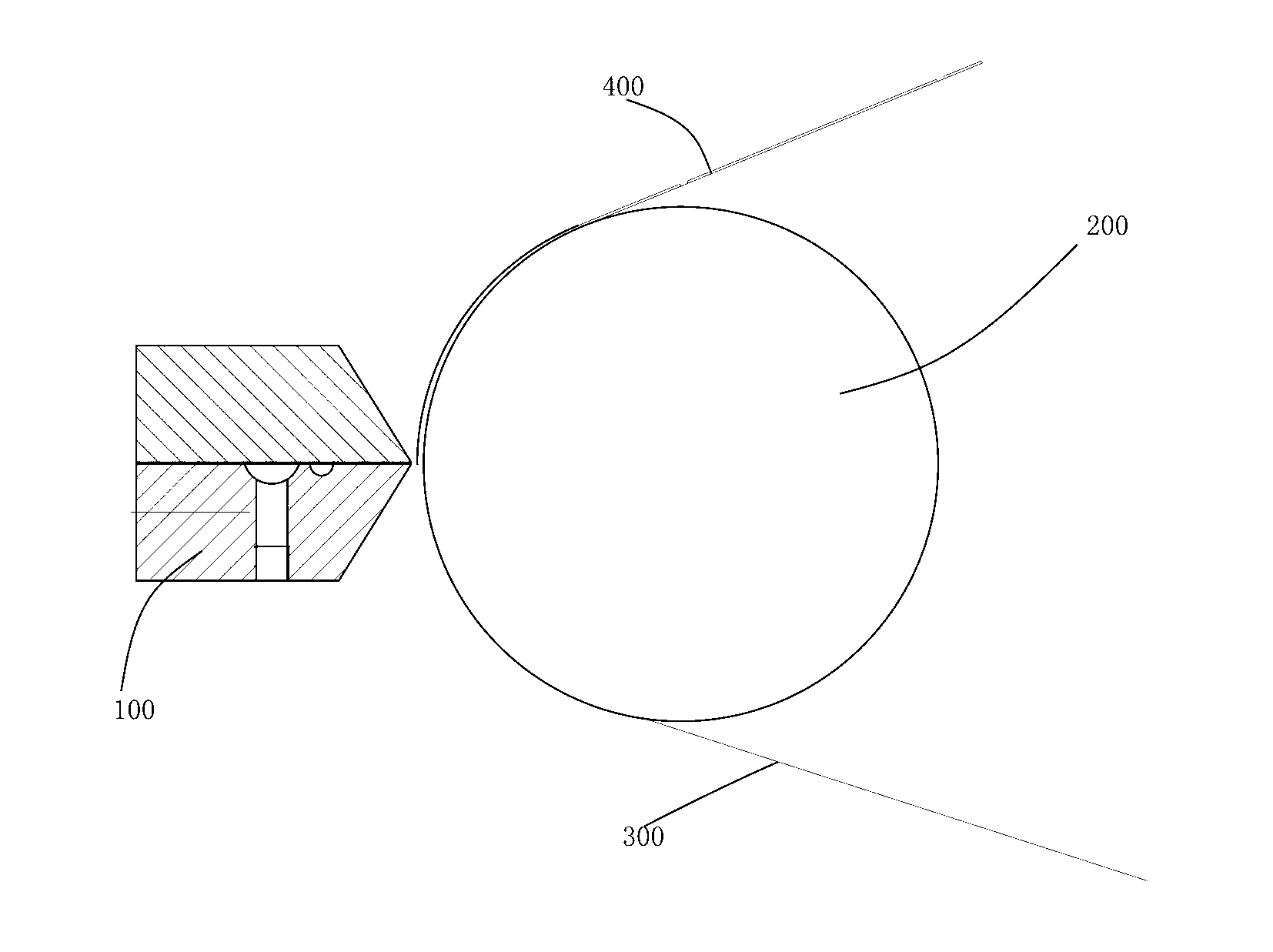

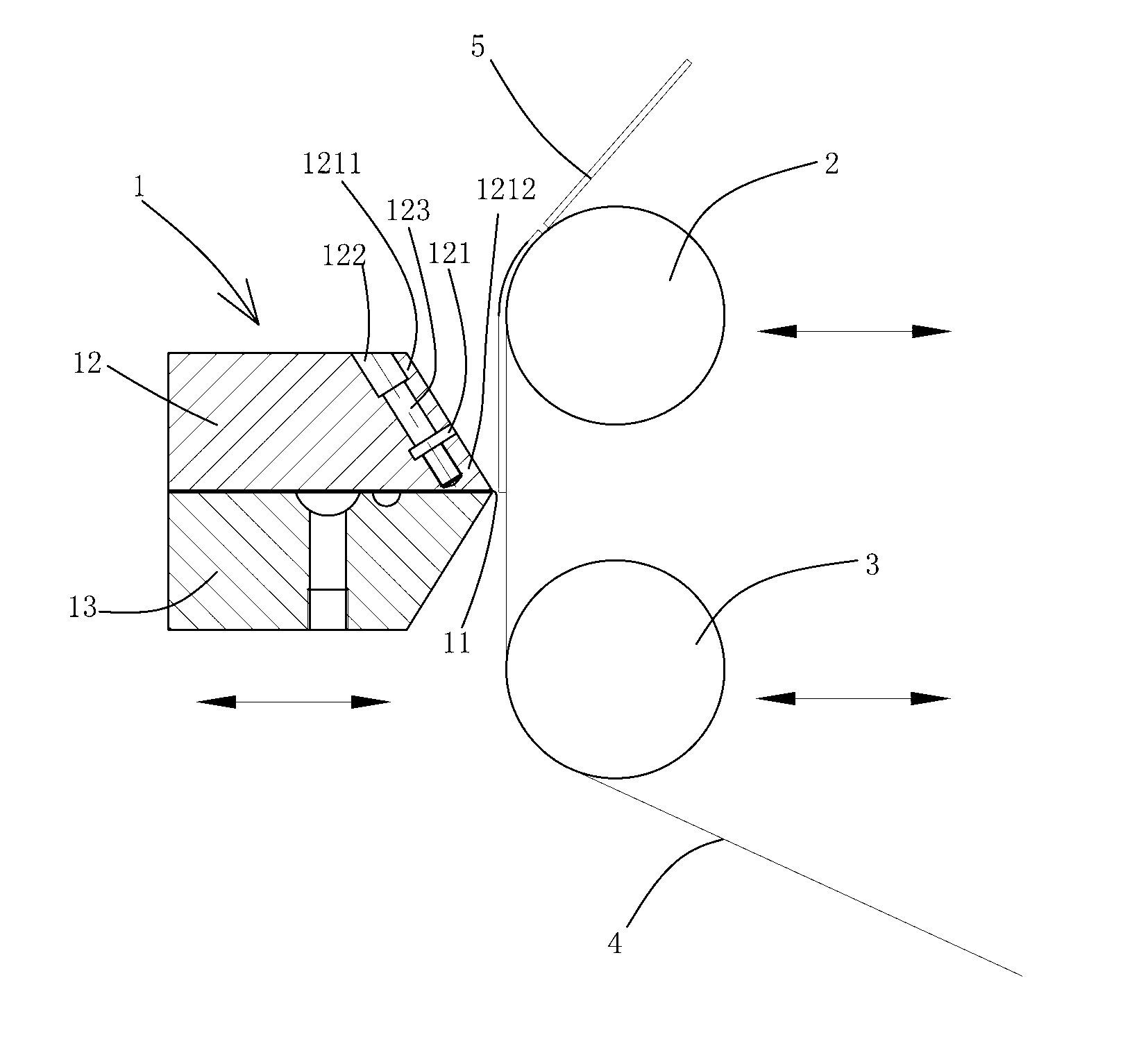

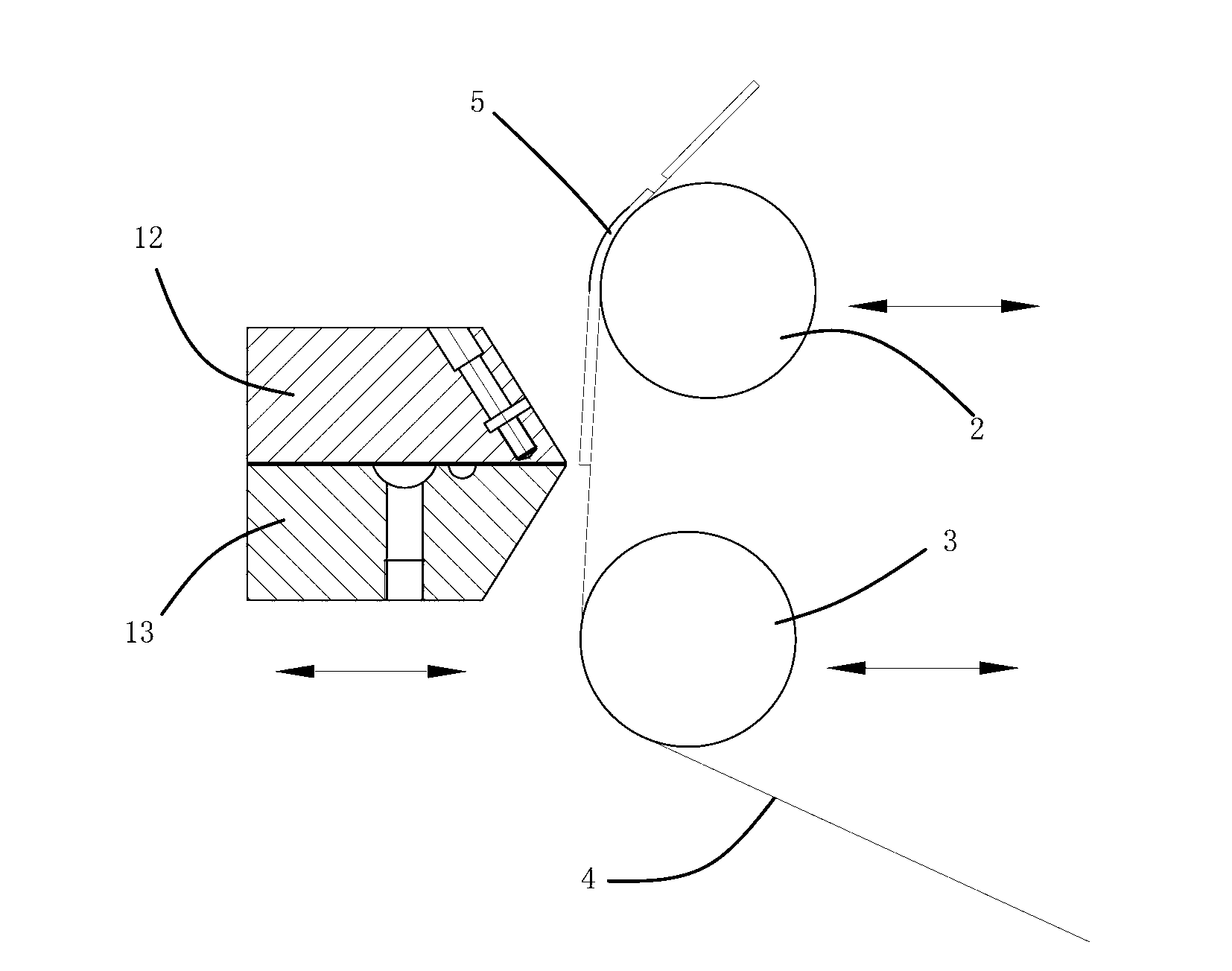

[0038] The invention provides a back-rollerless intermittent extrusion coating method, which includes setting a first passing roller and a second passing roller, the first passing roller and the second passing roller are arranged in parallel with a predetermined distance; Going in one direction through the first passing roller and the second passing roller; an extrusion head is arranged, and the extrusion head is located on the side of the base material away from the first passing roller and the second passing roller, and the extrusion The slit of the extrusion head faces the surface of the substrate between the first passing roller and the second passing roller, and the slurry is intermittently applied to the substrate from the slit of the extrusion head. In this way, the extrusion head can be placed as close as possible to the surface of the substrate, and the purpose of thin coating can be achieved. After testing, the thickness of the coating layer can be less than 20 μ. Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com