Composite fault diagnosis method and system of gear case

A composite fault and diagnosis method technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as wrong judgment of gear running status, achieve fast calculation speed, high extraction and recognition ability, and avoid sudden accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Take the fault of wind power generator gear box as example below, the present invention is described in detail:

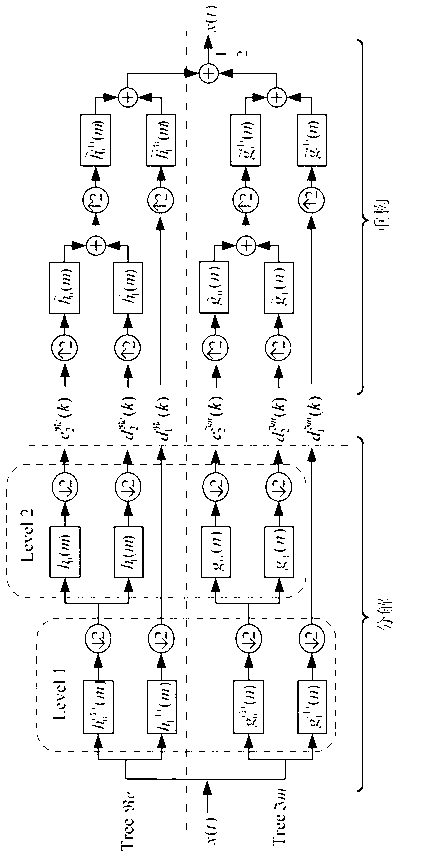

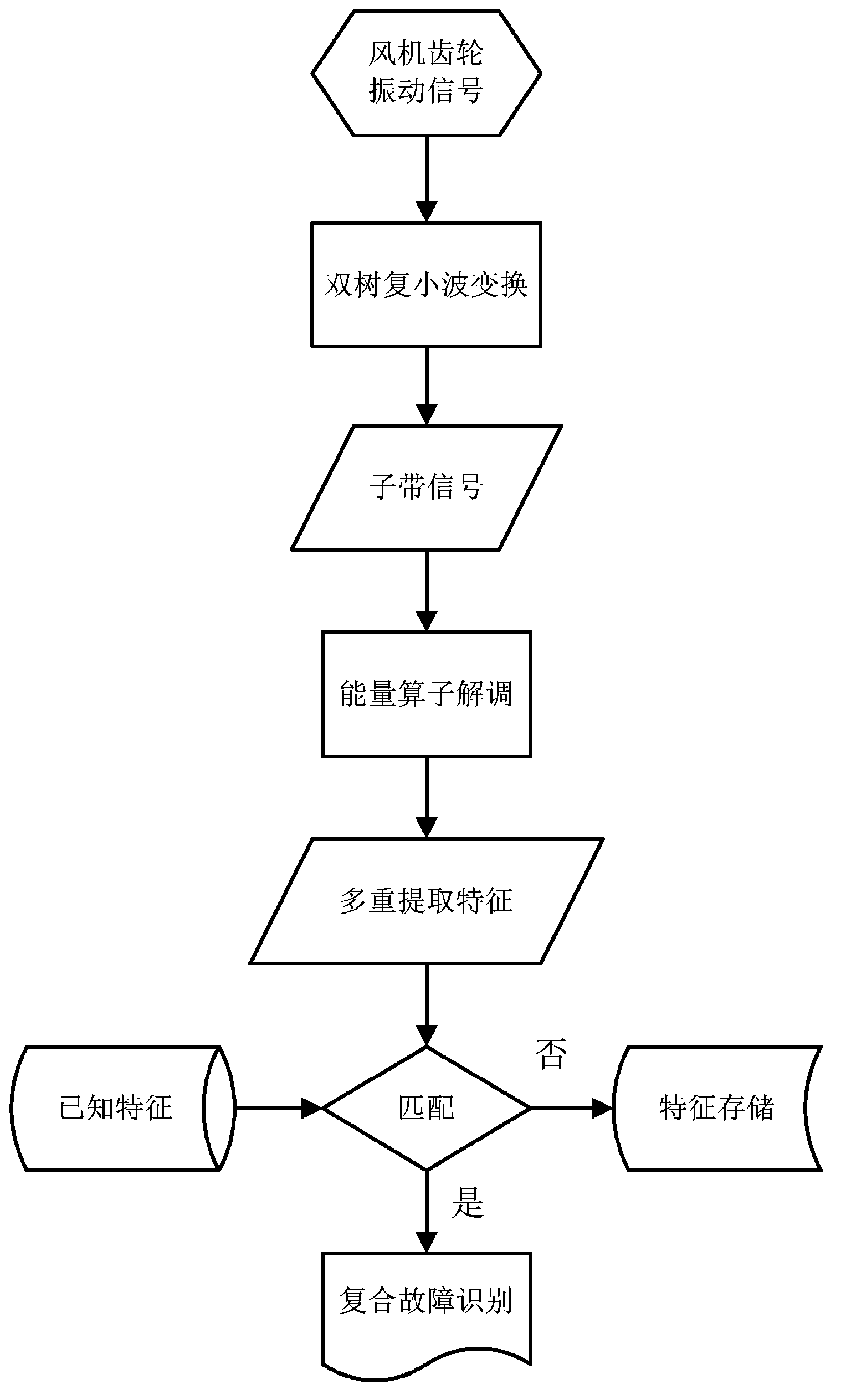

[0046] see figure 1 , a gearbox compound fault diagnosis method, comprising the steps of:

[0047] (1) The acceleration vibration sensor is used to pick up the vibration signal of the gearbox, and the acceleration sensor is installed on the end cover of the input shaft of the gearbox to be tested.

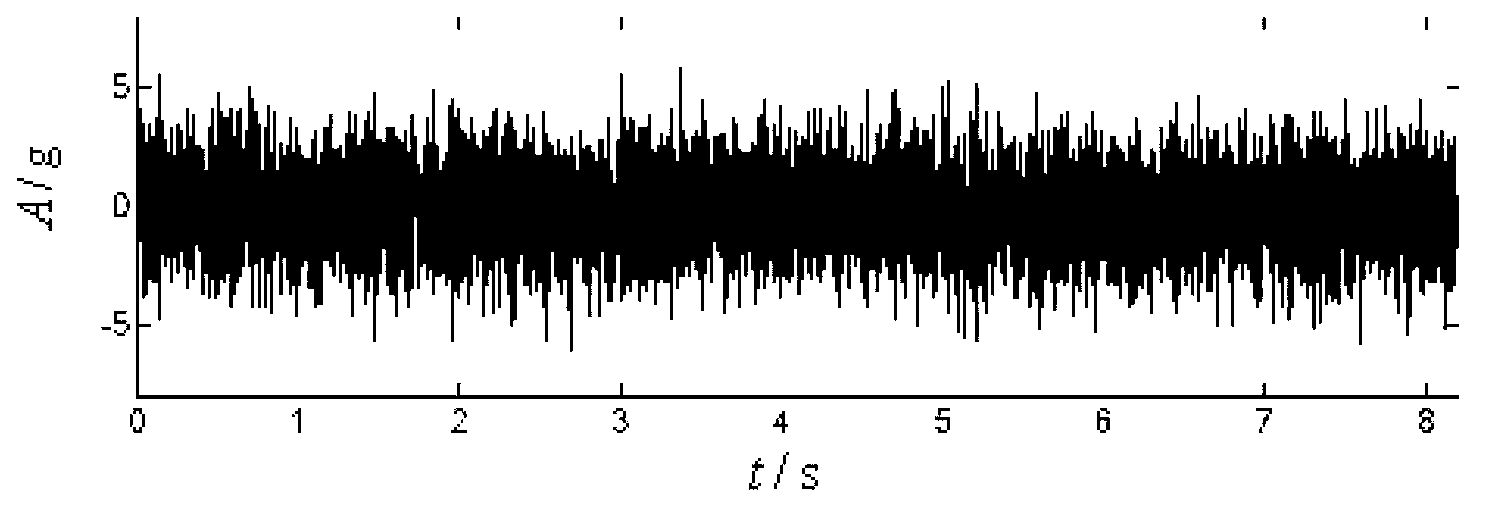

[0048] In this embodiment, the output shaft speed of the wind power generating set is measured to be 495r / min (the rotation frequency is 8.25Hz), the number of teeth of the pinion gear of the gearbox is 20, the number of teeth of the large gear is 151, the transmission ratio is 0.132, and the rotation frequency of the pinion gear is 8.25Hz. The meshing frequency of the fan gearbox is 165Hz. During the operation of the fan, the gearbox vibrates violently. An acceleration vibration sensor is used to pick up the vibration signal of the gearbox. The acceleration s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com