Ceramic radome crack automatic detection method

A ceramic antenna and automatic detection technology, which is applied in the direction of optical testing flaws/defects, can solve problems such as large detection errors and inability to guarantee product detection quality, and achieve accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

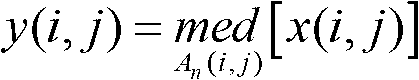

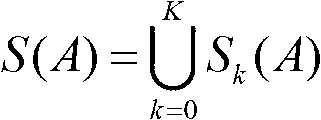

[0022] Set the light source inside the ceramic radome, and then use the CCD camera outside the radome to automatically collect the transmission images of different parts of the radome, and process the collected grayscale images according to the following steps:

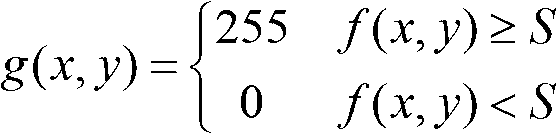

[0023] Step 1): In order to increase the contrast between the crack defect area and the non-defect area in the collected grayscale image and highlight the crack defect area, it is necessary to perform contrast enhancement processing, which is processed by segmented linear change, and the transformation formula is:

[0024] g ( x , y ) = c a × f ( x , y ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com