A double-stator through-hole bearing permanent magnet gyro motor

A double-stator, stator technology, applied in the field of gyroscope, can solve the problems of bearing gap change, bearing being polluted by the stator, etc., and achieve the effect of consistent processing size, reducing copper consumption and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

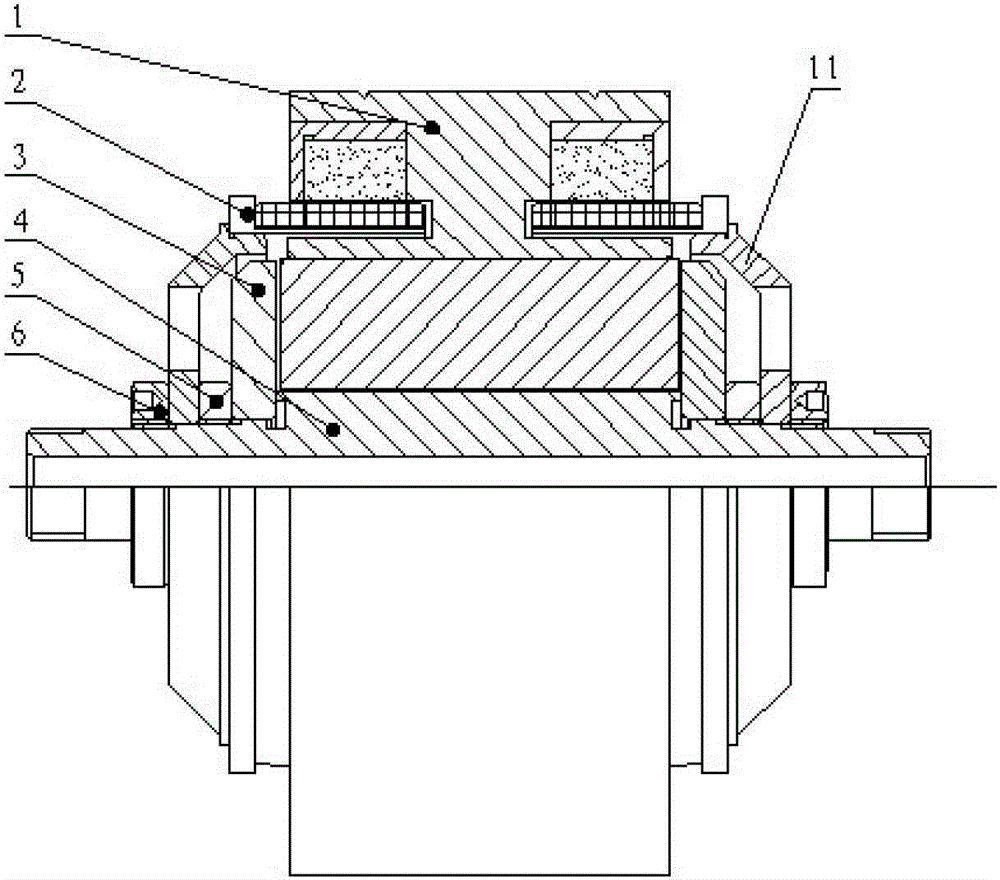

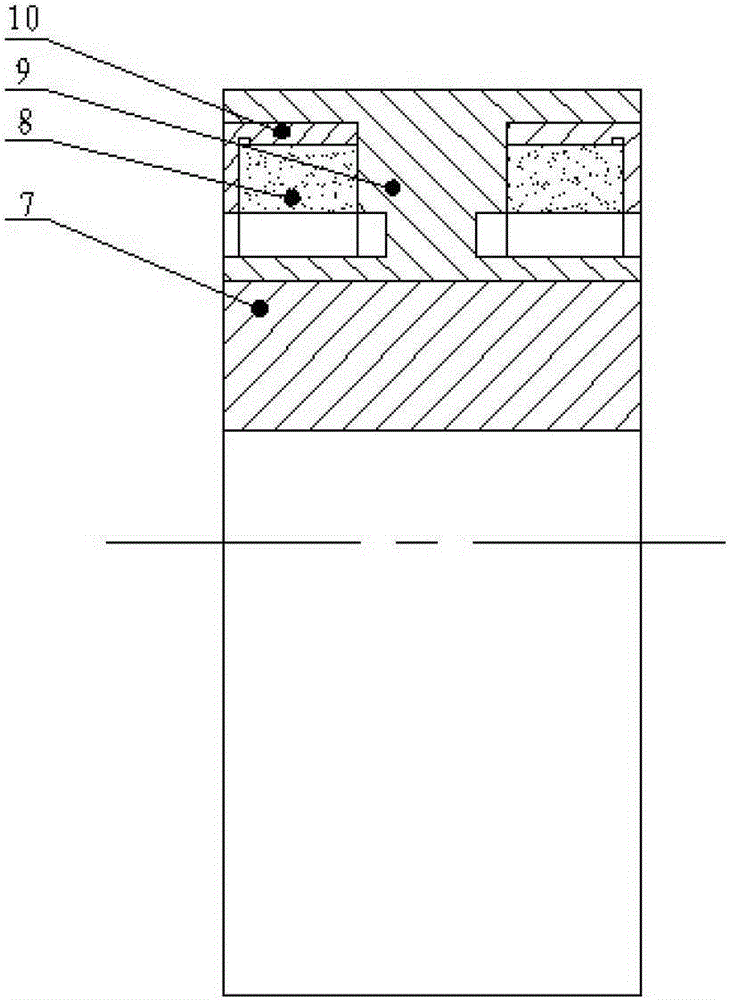

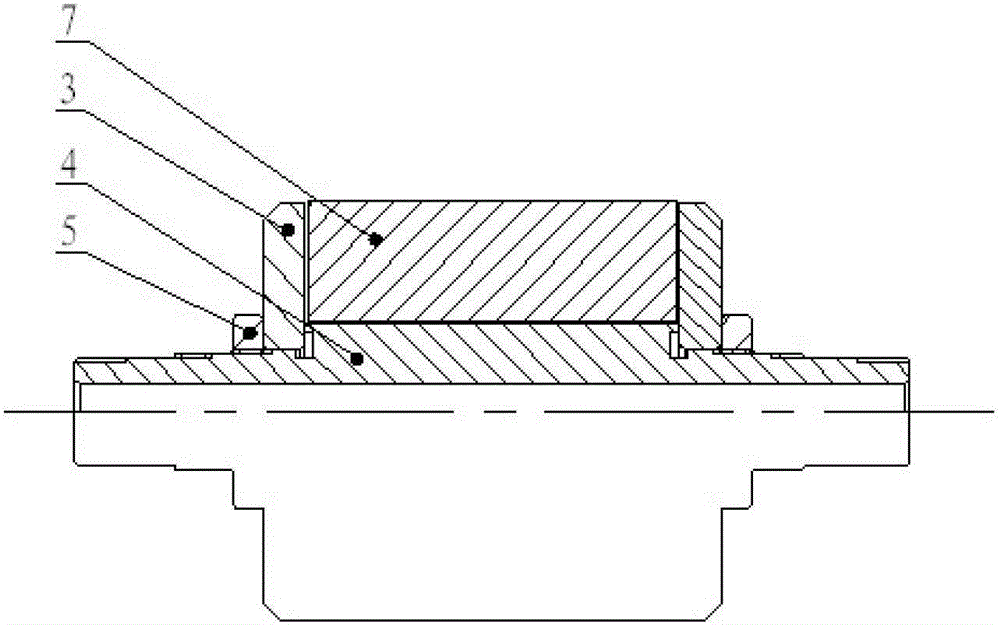

[0023] A double-stator through-hole bearing permanent magnet gyro motor includes a stator 2, a rotor 1, a thrust plate 3 and a shaft 4. The innovation of the present invention is that the rotor is composed of bearing sleeve 7, magnetic steel 8, rotor ring 9 and magnetic conduction ring 10, the bearing sleeve is coaxially installed in the rotor ring, and the left and right sides of the rotor ring are symmetrically made into two ring-shaped installations. A ring-shaped magnetic steel is coaxially installed in each annular installation groove. The magnetic steel is a permanent multi-pole integral ring magnetic steel. A magnetic conduction ring is installed between the outer wall of each magnetic steel and the rotor ring. The rotor Both the ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com