Antibacterial deodorization partial pressure decreasing type pressure socks

A compression stocking and deodorant technology, applied in socks, pantyhose, clothing, etc., can solve the problem of no antibacterial and deodorant effect, and achieve the effects of novel appearance design, prevention and relief of swelling, and comfortable wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

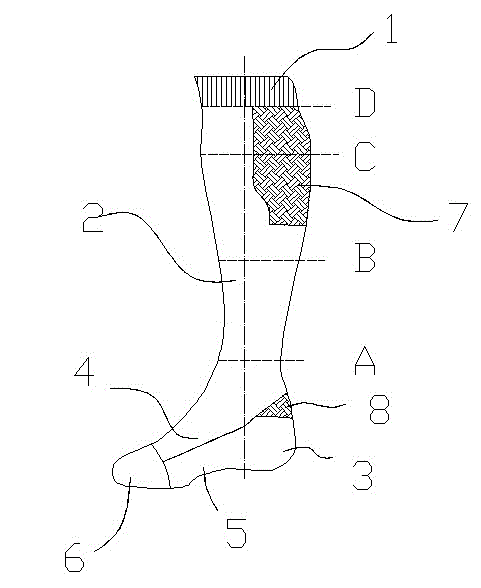

[0018] Such as figure 1 The shown antibacterial and deodorant partial pressure decreasing pressure socks are composed of a sock opening 1, a sock tube 2, a sock heel 3, a sock face 4, a sock bottom 5 and a sock toe 6. The sock opening 1 and the sock tube 2 The sock heel 3, sock top 4 and sock bottom 5 are woven according to the shape of the human foot. The sock mouth 1, sock tube 2, sock heel 3, sock top 4, sock bottom 5 and sock toe 6 are without seam connection; the sock tube 2 is provided with a pressurized zone 7 corresponding to the position of the calf of the human body, and a triangular pressurized zone 8 is set at the joint between the heel and the sock tube, and the pressurized zones at both places are dense single-layer mesh structure.

[0019] The part where the sock mouth is connected with the sock tube corresponds to the place D under the human knee and the protuberance of the tibia. The pressure at this place is 32mmHg. The sock tube is located at the largest ci...

Embodiment 2

[0027] The specific scheme is the same as that in Example 1, the difference is that: the part where the sock opening and the sock tube are connected corresponds to the lower knee and tibial protuberance (D), where the pressure is 32mmHg, and the sock tube is located at the calf with the largest circumference (C), where the pressure is 18mmHg, the sock is located at the junction of the Achilles tendon and the calf muscle (B), where the pressure is 20mmHg, the sock is located at the thinnest part of the ankle circumference (A), where the The pressure is 21mmHg.

Embodiment 3

[0029] The specific scheme is the same as in Example 1, the difference is that: the part where the sock mouth and the sock tube are connected corresponds to the lower knee and tibial protuberance (D), where the pressure is 30mmHg, and the sock tube is located at the calf with the largest circumference (C), where the pressure is 20mmHg, the sock is located at the junction of the Achilles tendon and the calf muscle (B), where the pressure is 21mmHg, the sock is located at the thinnest part of the ankle circumference (A), where the The pressure is 21mmHg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com