Hydraulic cylinder

A technology for hydraulic cylinders and cylinders, which is applied in the field of piston rod anti-rotation mechanisms, and can solve problems such as inability to adjust the solution, difficulty in adjusting the piston rod and cylinder, and inability to adjust the load state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be noted that the features in the various embodiments of the present invention may be combined with each other in the absence of explicit limitation or conflict. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0039] In order to overcome the defects of the hydraulic cylinder in the prior art, the present invention provides an improved hydraulic cylinder and a hydraulic cylinder with the same.

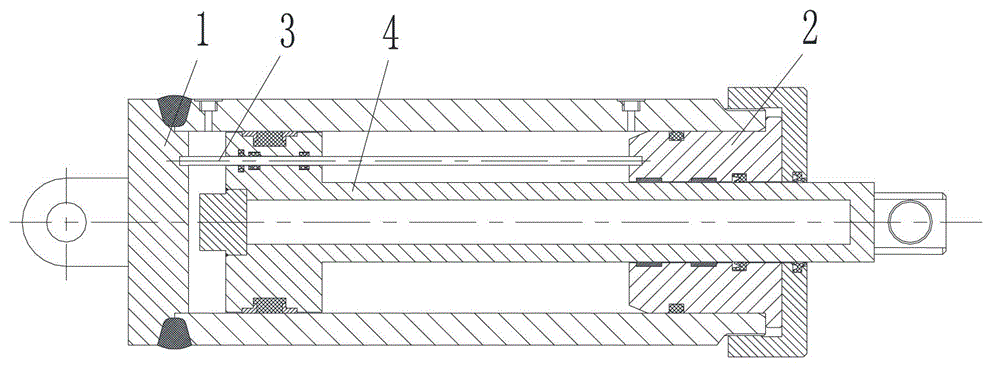

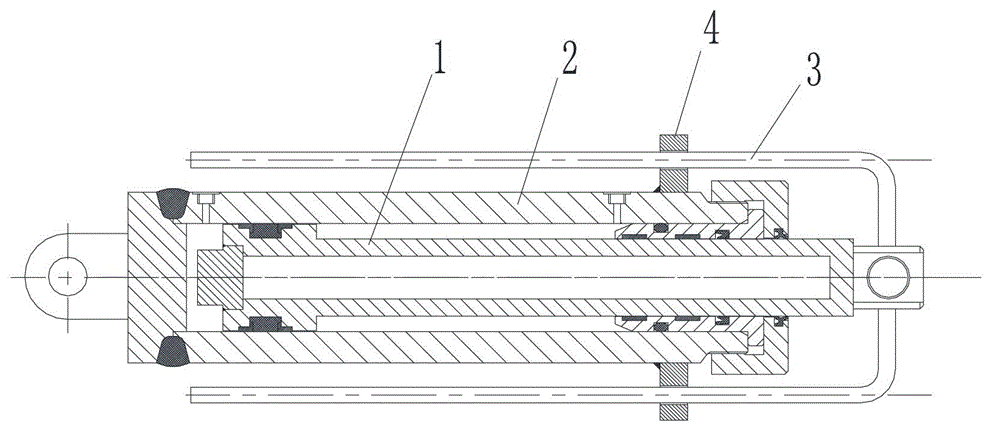

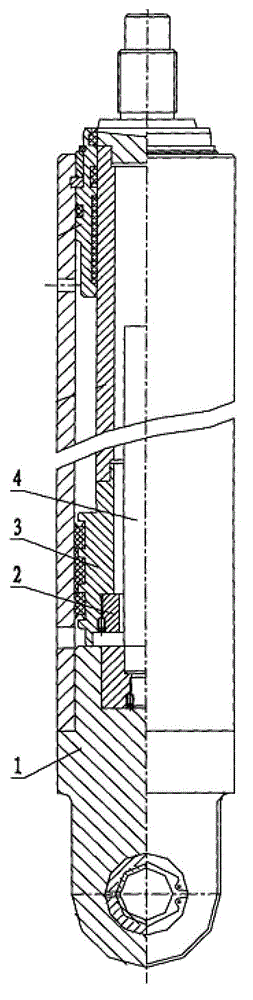

[0040] Figure 5 is a structural schematic diagram of a hydraulic cylinder according to an embodiment of the present invention, Figure 6 is along Figure 5 The sectional view of the A-A line only shows the guide block and the guide rod.

[0041] Such as Figure 5 As shown, the cylinder barrel 3 of the hydraulic cylinder in this embodiment is a round tube with an inner hole that has been precisely machined, and the outer circles of both ends are processed with external threads for connection, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com