High-efficiency bolt installation structure

An installation structure and high-efficiency technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as affecting installation efficiency and easy rotation of bolts, and achieve the effect of improving installation efficiency, connection efficiency and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

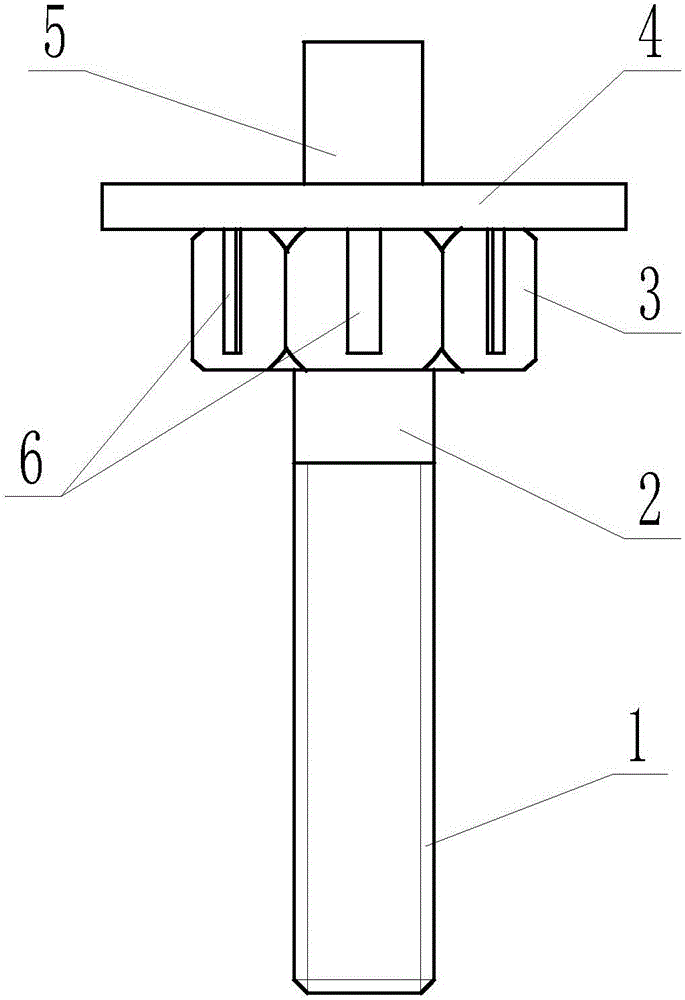

[0013] Such as figure 1 As shown, the high-efficiency bolt installation structure provided by the present invention includes a screw 2 whose top end is a nut 3 and whose end is a threaded section 1, and also includes a limit mechanism, which includes a baffle 4 whose diameter is larger than that of the screw. The diameter of the cap 3 is affixed with a handle 5 at the lower top of the baffle plate 4, and a plurality of limiting plates 6 are evenly affixed to the bottom of the baffle plate 4, and the limiting plates 6 are attached to the side walls of the nut 3.

[0014] In order to improve the limiting and anti-rotation efficiency and match the hexagonal nut 3, the number of the limiting rods 6 is 3 or 6.

[0015] In order to prevent the limiting plate 6 from interfering with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com