Double-row octagonal pipe gripping apparatus

An octagonal and gripper technology, applied in the field of double-row octagonal tube grippers, can solve the problems of inability to adjust, limited use range, low stability, etc., and achieves simple structure, increased stability and safety, and high tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

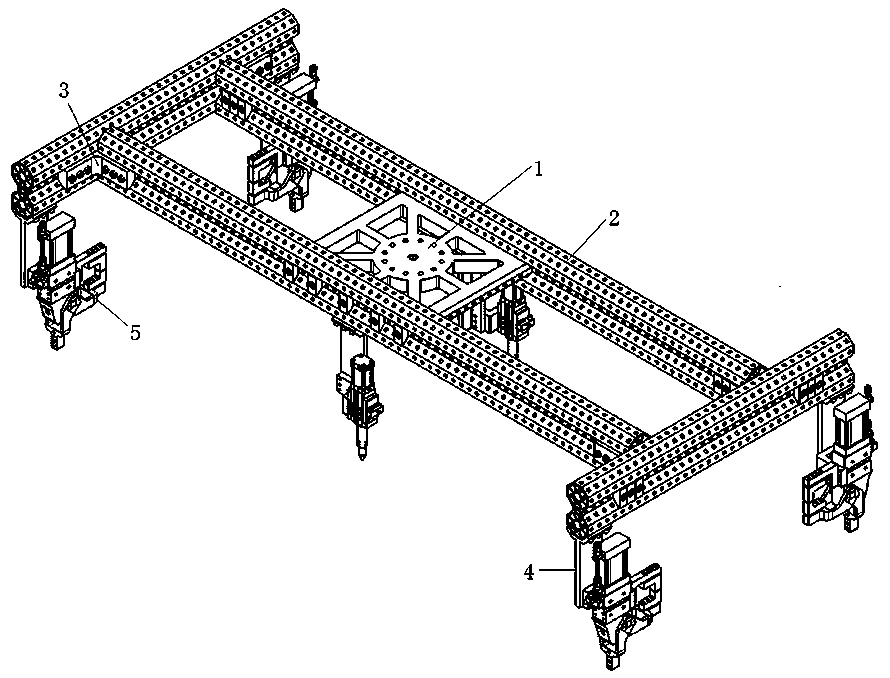

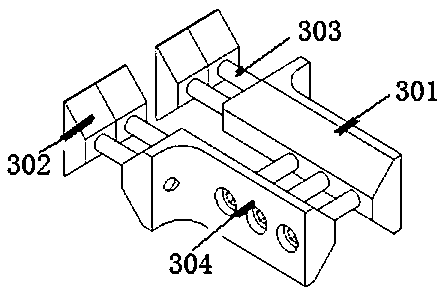

[0027] A double-row octagonal pipe gripper, including a connecting plate 1, a double-row octagonal pipe 2, a connecting assembly 3, a connecting piece 4 and a clamping unit 5, the number of the double-row octagonal pipes 2 is four, and four double-row The octagonal tubes 2 vertically form a frame and the four corners of the frame are fixed by connecting components 3. The connecting plate 1 is located in the center of the frame and the two ends of the connecting plate 1 are respectively in contact with two double rows of octagonal tubes 2. The clamping unit 5 The number is multiple, and multiple clamping units 5 are respectively fixed on the lower ends of the four corners of the frame and the lower end of the connecting plate 1 through connecting pieces 4 . The connecting assembly 3 comprises a first connecting block 301, a second connecting block 302, a fastening pin 303 and a third connecting block 304, the first connecting block 301 is fixed to one side of the double-row octa...

Embodiment 2

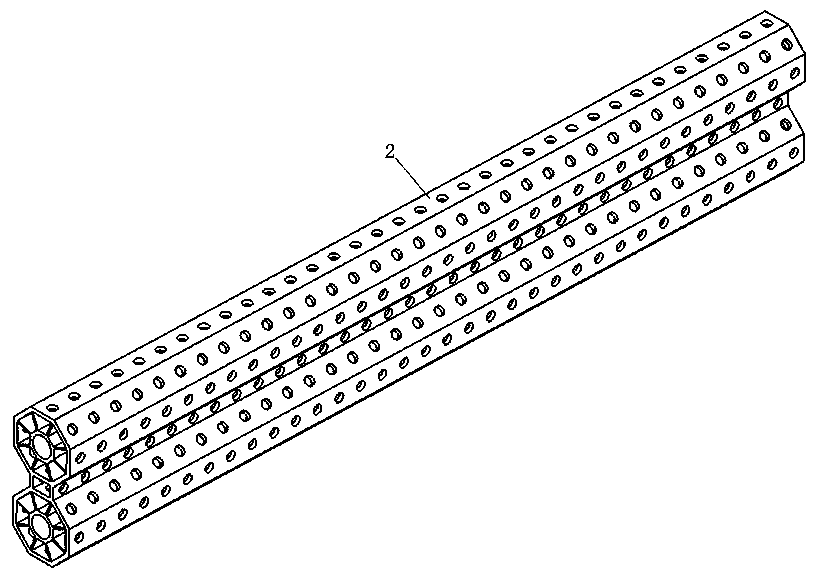

[0029] A double-row octagonal pipe gripper, including a connecting plate 1, a double-row octagonal pipe 2, a connecting assembly 3, a connecting piece 4 and a clamping unit 5, the number of the double-row octagonal pipes 2 is four, and four double-row The octagonal tubes 2 vertically form a frame and the four corners of the frame are fixed by connecting components 3. The connecting plate 1 is located in the center of the frame and the two ends of the connecting plate 1 are respectively in contact with two double rows of octagonal tubes 2. The clamping unit 5 The number is multiple, and multiple clamping units 5 are respectively fixed on the lower ends of the four corners of the frame and the lower end of the connecting plate 1 through connecting pieces 4 . The outline of the double-row octagonal tube 2 is a sixteen-sided 8-shaped shape, and there are a plurality of positioning mounting holes evenly distributed on the double-row octagonal tube 2, which can be connected to differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com