Rotor of rotating electric machine, rotating electric machine, and end face member of rotor

A technology of rotating motor and end face, applied in the direction of magnetic circuit rotating parts, electrical components, electric components, etc., can solve problems such as poor work efficiency, and achieve the effect of efficient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

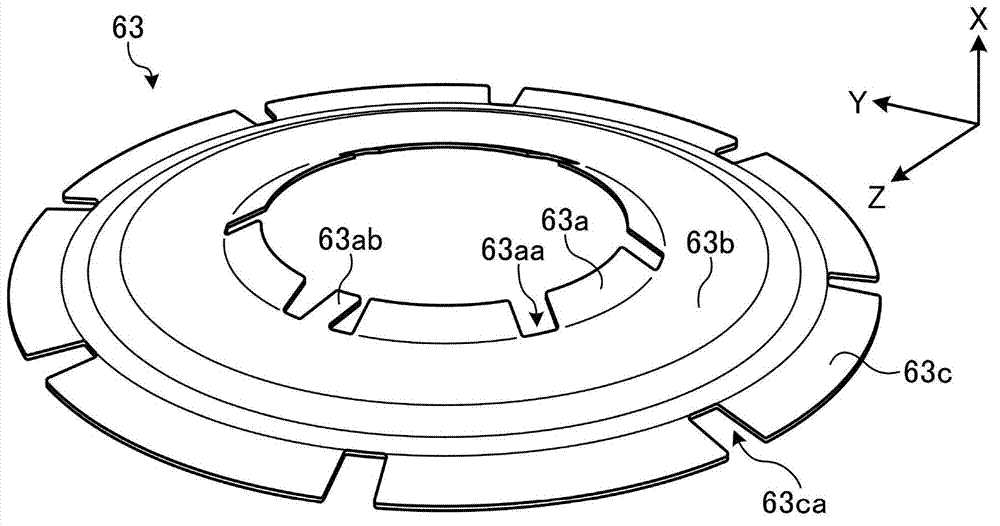

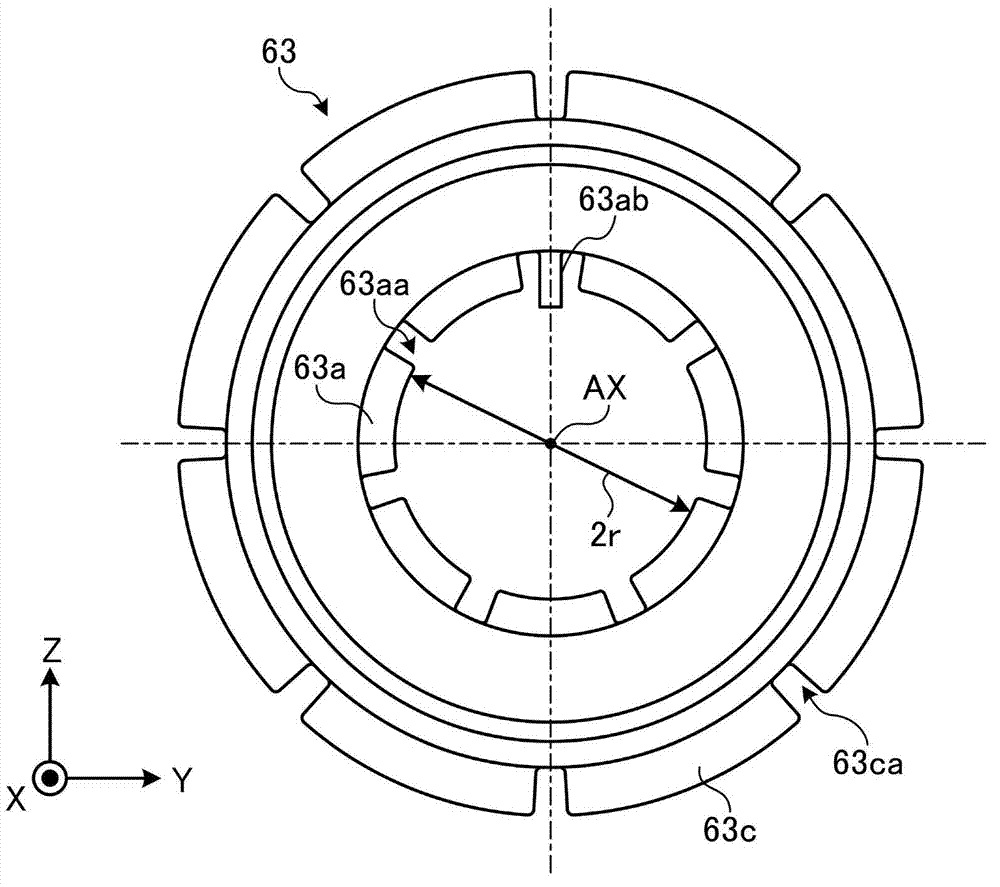

[0050] First of all, for the structure of the rotating electrical machine involved in the embodiment, use figure 1 Be explained. figure 1 It is a longitudinal sectional view showing the structure of the rotating electric machine 1 according to the embodiment. In addition, in figure 1 In , in order to make the description easy to understand, a three-dimensional Cartesian coordinate system including a Z-axis whose positive direction is vertically upward is shown. The Cartesian coordinate system is also shown in the other figures used in the following description.

[0051] In addition, in the following, regarding a plurality of constituent elements, there may be cases where only one of the plurality is designated with a reference numeral, and the reference numerals are omitted for the other components. In this case, it is assumed that the structures of the respective components are the same.

[0052] Such as figure 1 As shown, the rotating electric machine 1 according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com