Door closer

A technology of door closers and shells, which is applied in the field of door closers and can solve problems such as high leakage loss and low spring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

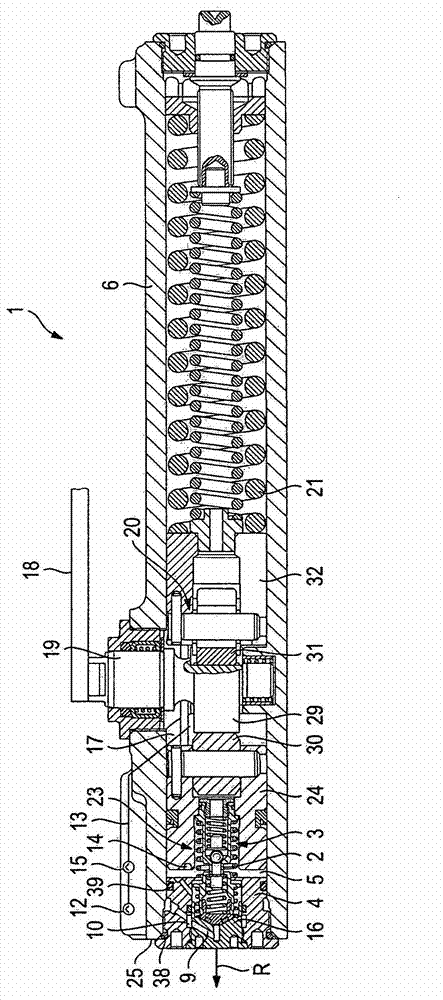

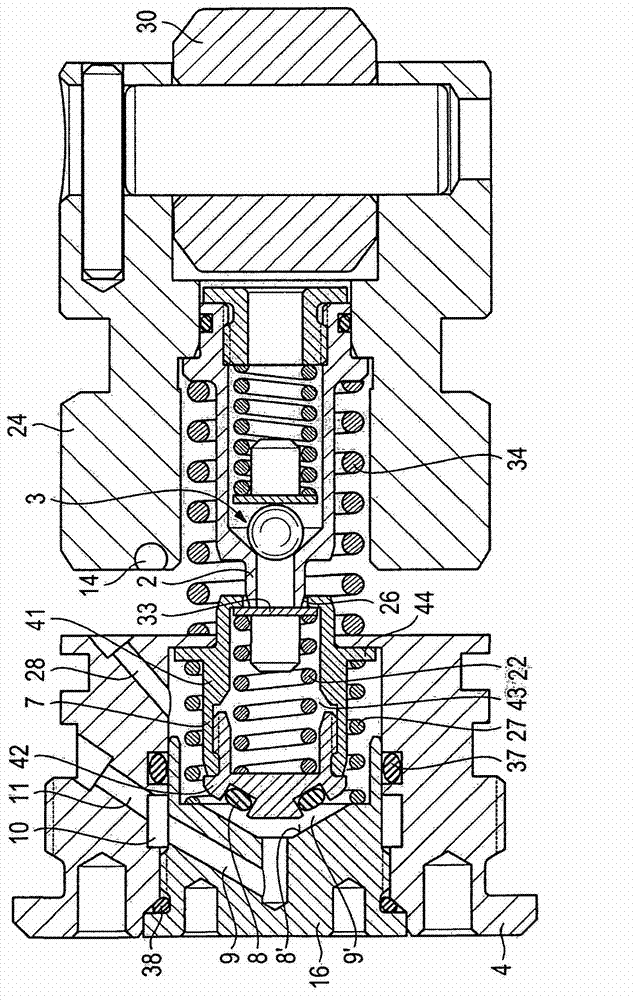

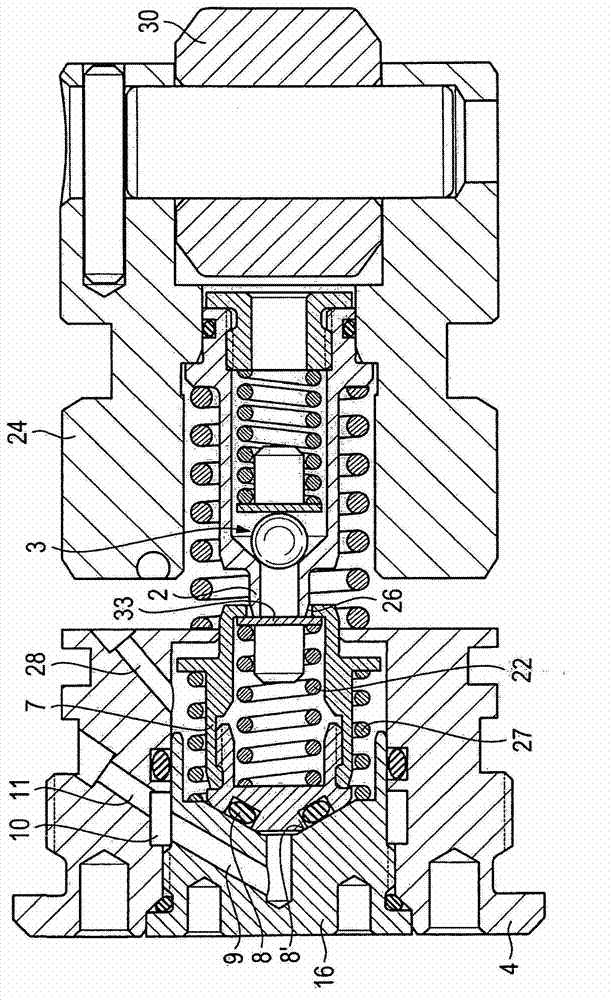

[0038] figure 1A door closer 1 according to the invention is shown in FIG. 1 , provided with a housing 6 . A drive device 20 is arranged in the housing 6, which device can be coupled via the closer shaft 19 and the arm assembly 18 to a door, which is not shown in detail in the figures. The drive device 20 is preferably configured as a cam drive with a cam disc 29 and with two rollers 30 and 31 which are arranged in a torque-proof manner on the shutter shaft 19 and which bear against the on the cam disc 29. In this case, the roller 30 is supported at the damping piston 24 , while the roller 31 is arranged at the drive piston 32 , which is in operative connection with the energy storage spring 21 , which is arranged in the housing 6 .

[0039] Furthermore, the door closer 1 has a hydraulic damper 23 . The device comprises a damping piston 24 arranged in the housing 6 , which is guided in the damping cylinder 5 . As mentioned above, the damping piston 24 is in operative conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com