Perforated pipe deburring machine and cutter thereof

A perforated pipe and deburring machine technology, applied in the field of pipe fittings processing equipment, can solve the problems of stagnant deburring work, overload damage of the power head, and different burrs, so as to avoid knife jamming, low maintenance cost and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

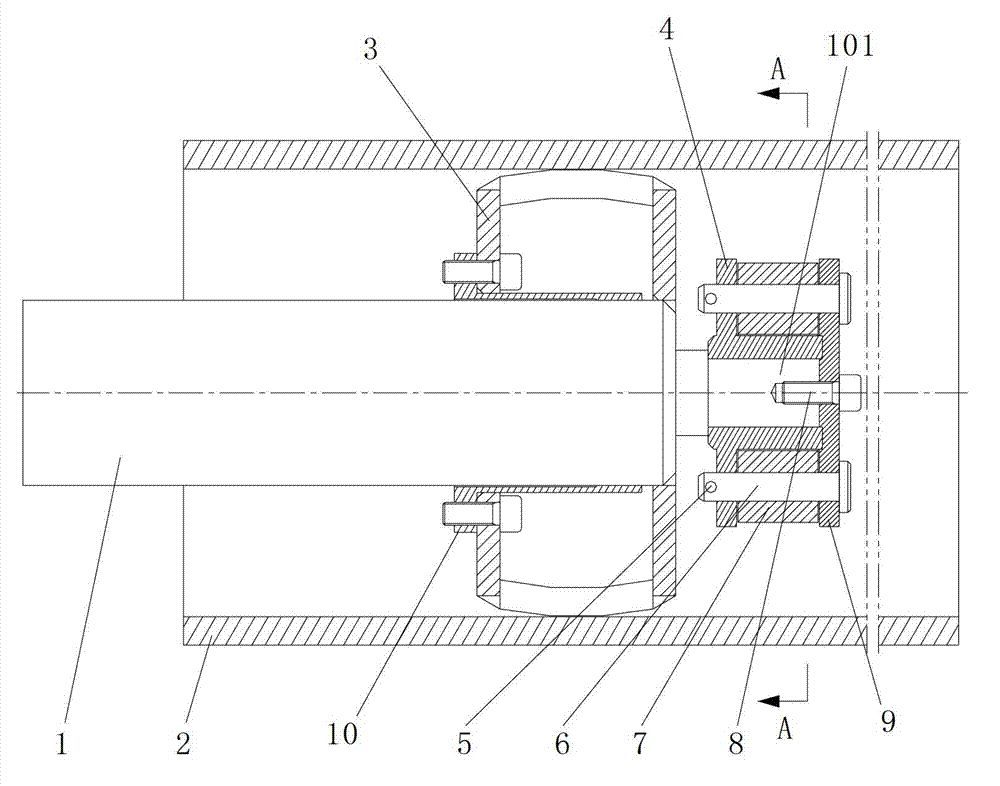

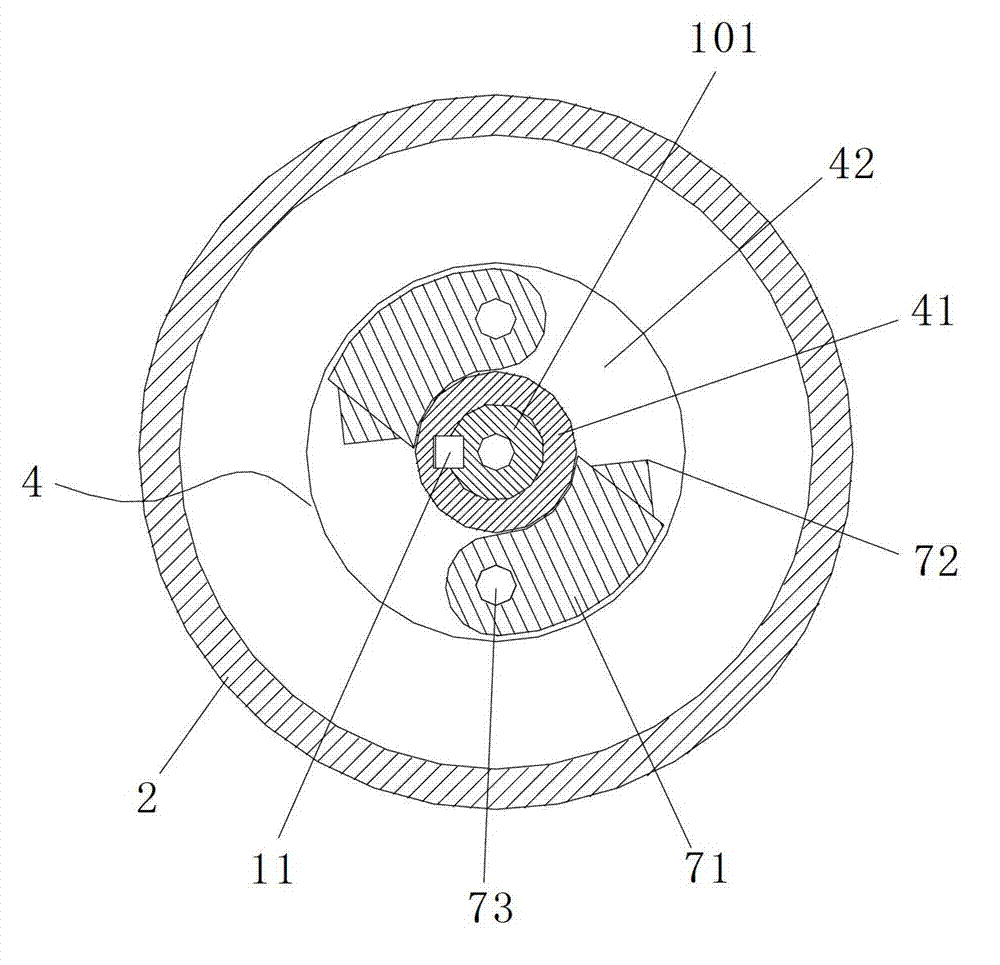

[0021] figure 1 It is a structural sectional view of the power head part of the perforated tube of the present invention in the perforated tube; figure 2 for figure 1 The A-A cutaway diagram. The cutter for the punching tube destacker includes a cutter holder 4 on which at least one eccentric cutter 7 is eccentrically hinged. The number of eccentric cutters 7 can be determined according to actual conditions. Generally, there are only two eccentric knives 7, and the two eccentric knives 7 are axially symmetrically arranged on the knife seat.

[0022] As a preference of the above embodiment, the blade body 71 of the eccentric knife 7 is arc-shaped, and one end of the eccentric knife 7 has a pin hole 73 for the pin shaft 6 to pass through and to be hinged to the knife seat 4 . A kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com