Multifunctional returning mechanism

A material return mechanism and multi-functional technology, applied in the field of pressure machinery, can solve the problems of complex structure, large space occupied by the cylinder, discomfort and other problems, and achieve the effect of overcoming the complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

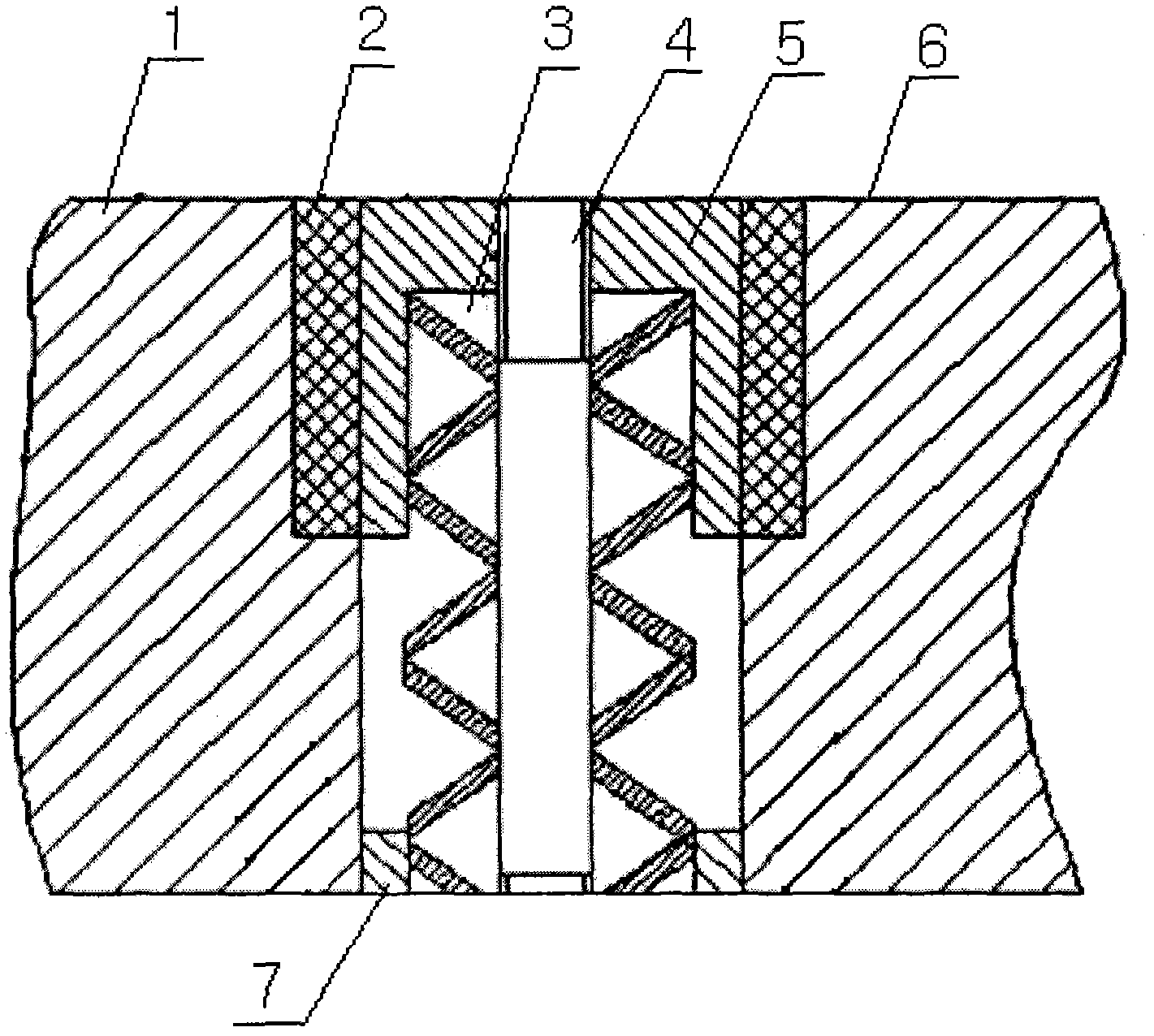

[0009] The multifunctional material return mechanism has a butterfly spring upper sleeve (5), and the butterfly spring upper sleeve (5) is installed on the upper part of the step hole of the workbench (1) through a lubricating bearing (2), and the two ends of the butterfly spring (3) Installed in the step hole of the butterfly spring lower sleeve (7), the positioning screw (4) is set in the hole of the butterfly spring (3), the upper end is fixed with the butterfly spring upper sleeve (5) by silk threads, and the lower end is lubricated Bearing is installed on the body (6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com