Downhole drilling equipment with cooling system

A cooling system and drilling equipment technology, applied in drilling equipment and methods, drilling equipment, drilling tools, etc., can solve the problems of affecting the working efficiency of coal mine equipment, poor ventilation conditions, high ambient temperature, etc. Reduce failure rate and overcome the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

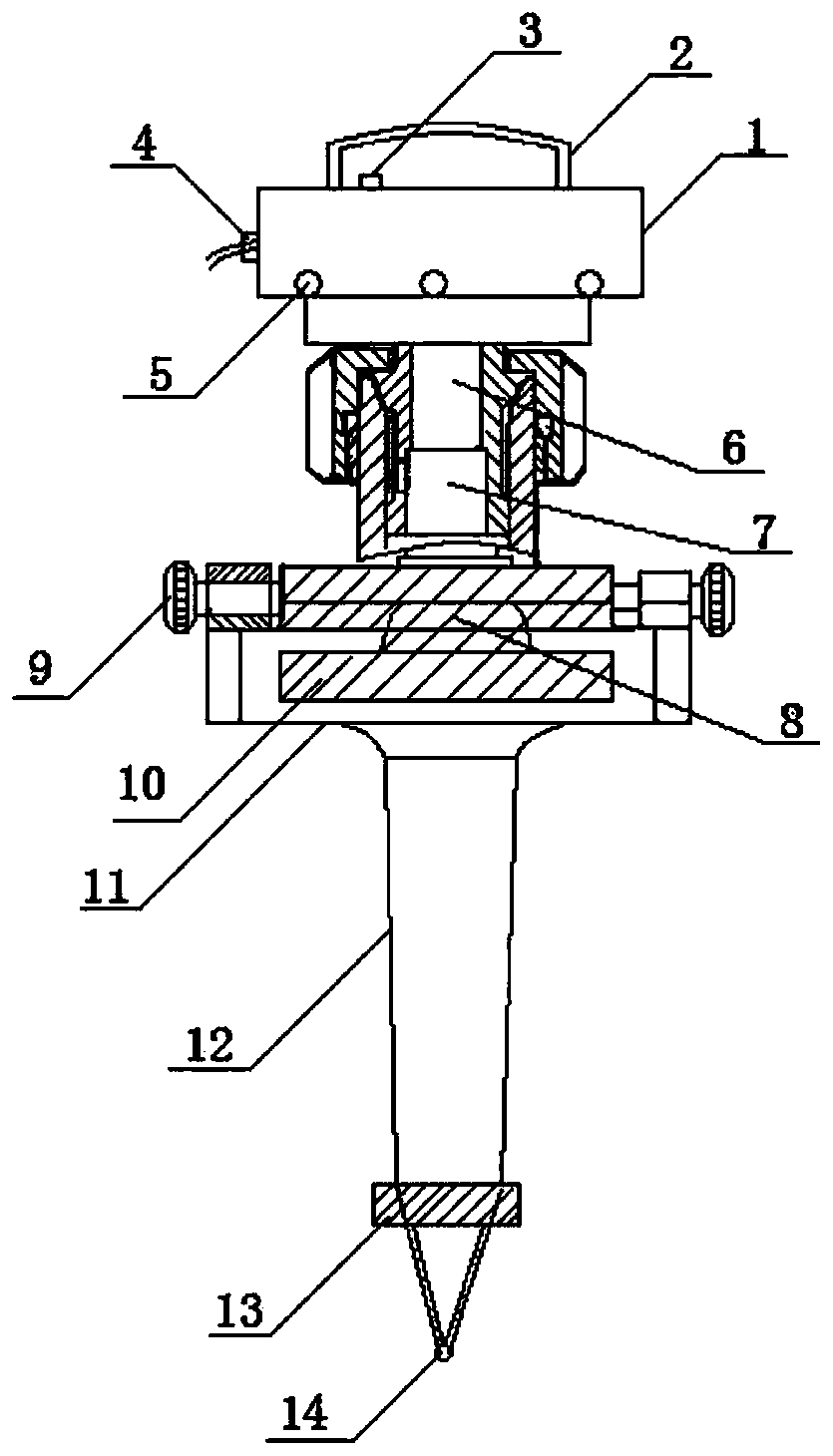

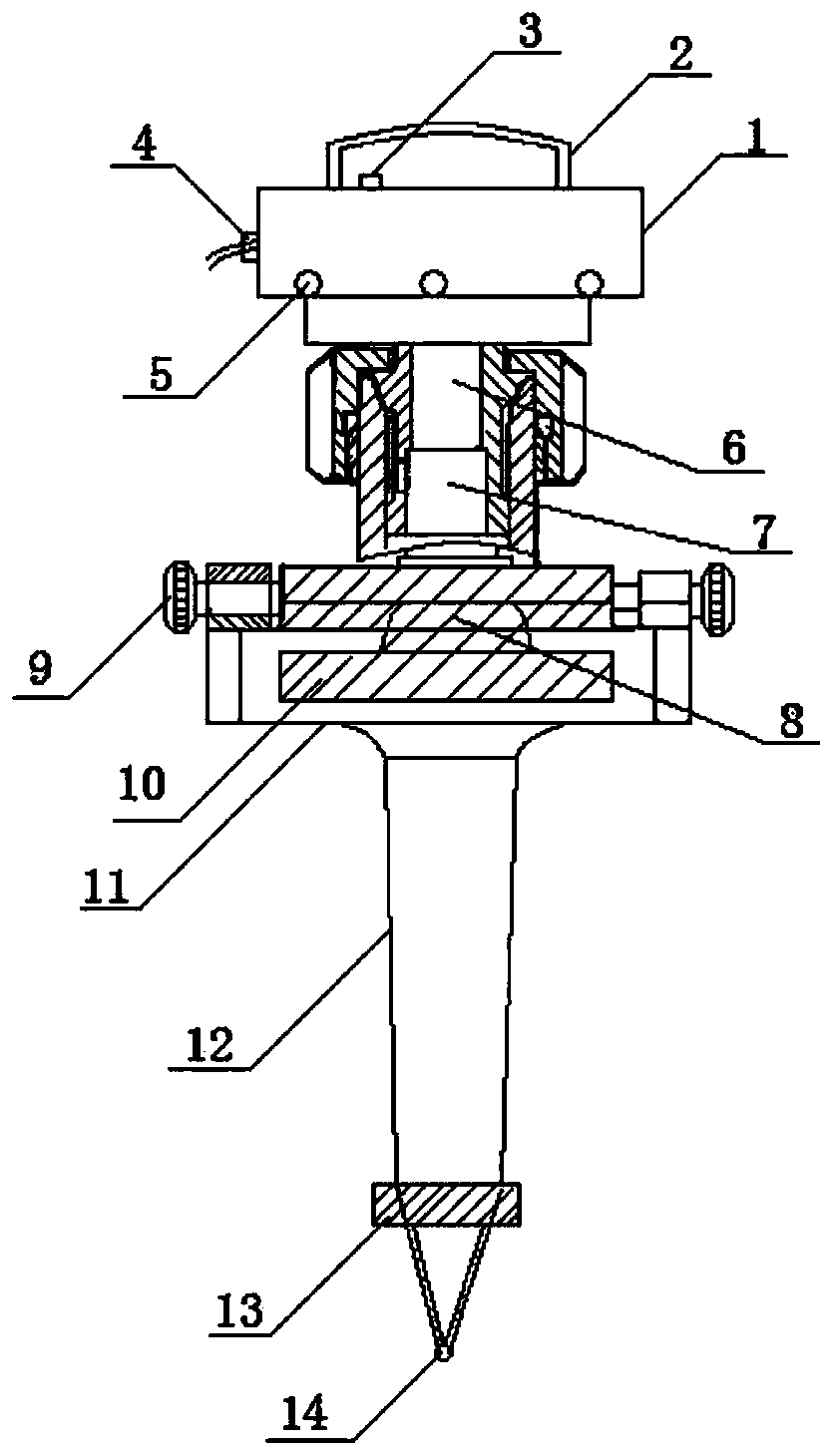

[0016] The specific structure of the present invention will be described in detail according to the accompanying drawings. The downhole drilling equipment with cooling system includes a bearing sleeve 11, a motor 1, a handle 2, a switch 3 and a wire box 4 are arranged on the bearing sleeve 11, and the motor 1 is fixed by fastening bolts 5; The lower end is connected with a transmission shaft 6, and the transmission shaft 6 is connected with the cam 8 through the adjustment pin 9 and the connecting key 7; It is connected with the cam 8, and the other end is connected with the drill bit 14 through the adjusting hole nut 13.

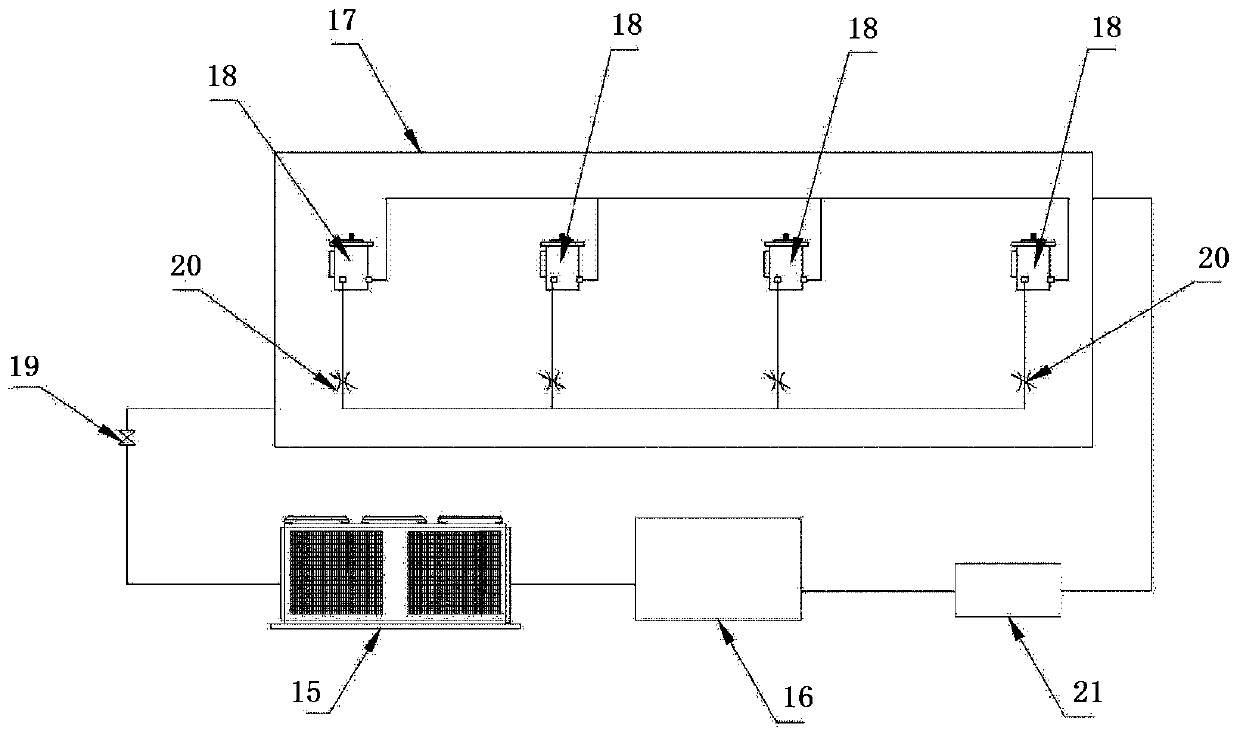

[0017] The cooling system includes a cooling unit 15 arranged on the motor, a coolant tank 16 and a plurality of cooled components 18 . These cooled components 18 are connected in parallel through cooling liquid pipelines to form cooled equipment group 17. An on-off valve 19 is provided on the pipeline between the cooled equipment group 17, and a diverter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com