Novel pipeless steel wire rope stranding machine

A technology of steel wire rope and stranding machine, which is applied in the field of steel wire stranding machine and tubeless steel wire rope stranding machine, which can solve the problems of speed limitation, high power consumption of rotation, and environmental impact, and achieve the goal of reducing noise sources and purifying the factory environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

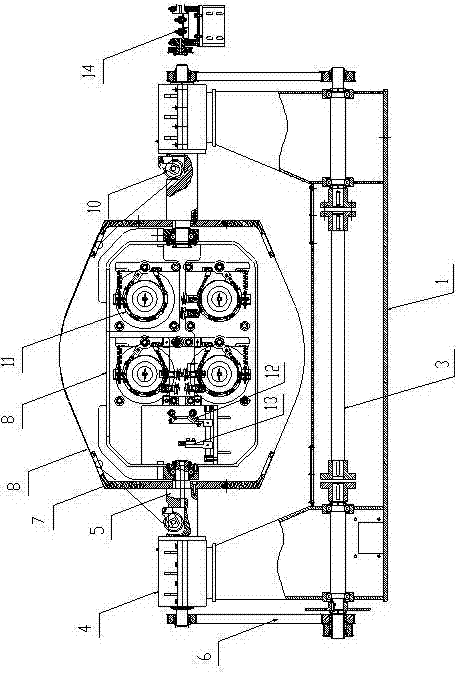

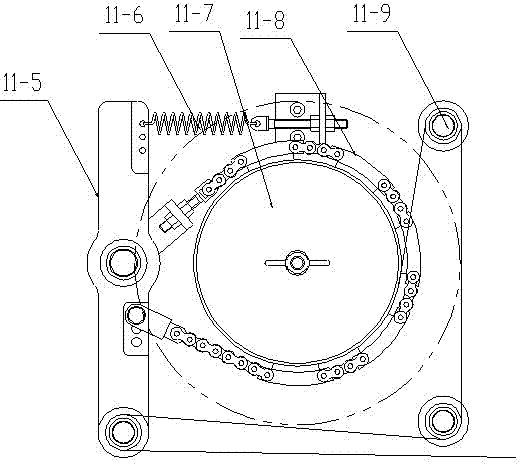

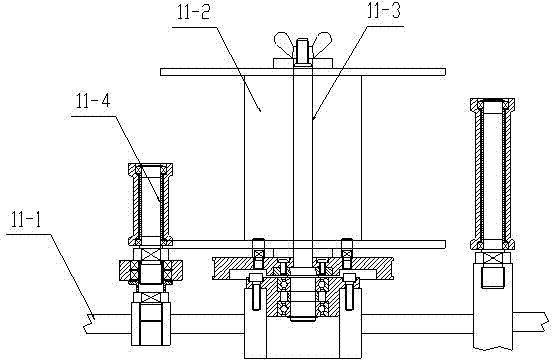

[0048] see figure 1 , the present invention relates to a novel tubeless wire rope stranding machine, which includes a frame 1, a main motor 2 and a twister 14, a connecting shaft 3 is arranged at the bottom of the frame 1, and two ends of the frame 1 Bearing housings 4 are fixed on both sides, and hollow rotating shafts 5 are arranged on the bearing housings 4 on both sides. The outer end of one of the rotating shafts 5 is connected with the main motor 2. In the hollow rotating shaft 5 Lead pulleys 10 are provided, the outer end of the rotating shaft 5 is connected to one end of the connecting shaft 3 through a belt 6, and the inner end of the rotating shaft 5 is connected to a rotating arm 7, and the rotating arm 7 is connected by a bow Connected with 8, between the rotating arms 7 is vertically provided with a pay-off base plate 9, the two ends of the pay-off base plate 9 are connected with the rotating shafts 5 on both sides through bearings, on both sides of the pay-out ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com