High-slip hydraulic coupler with multiple flow passages

A hydraulic coupling and multi-channel technology, applied in fluid transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as slow response, high motor power requirements, unfavorable savings, etc., to achieve protection and service life , improve economic efficiency, and solve overheating problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

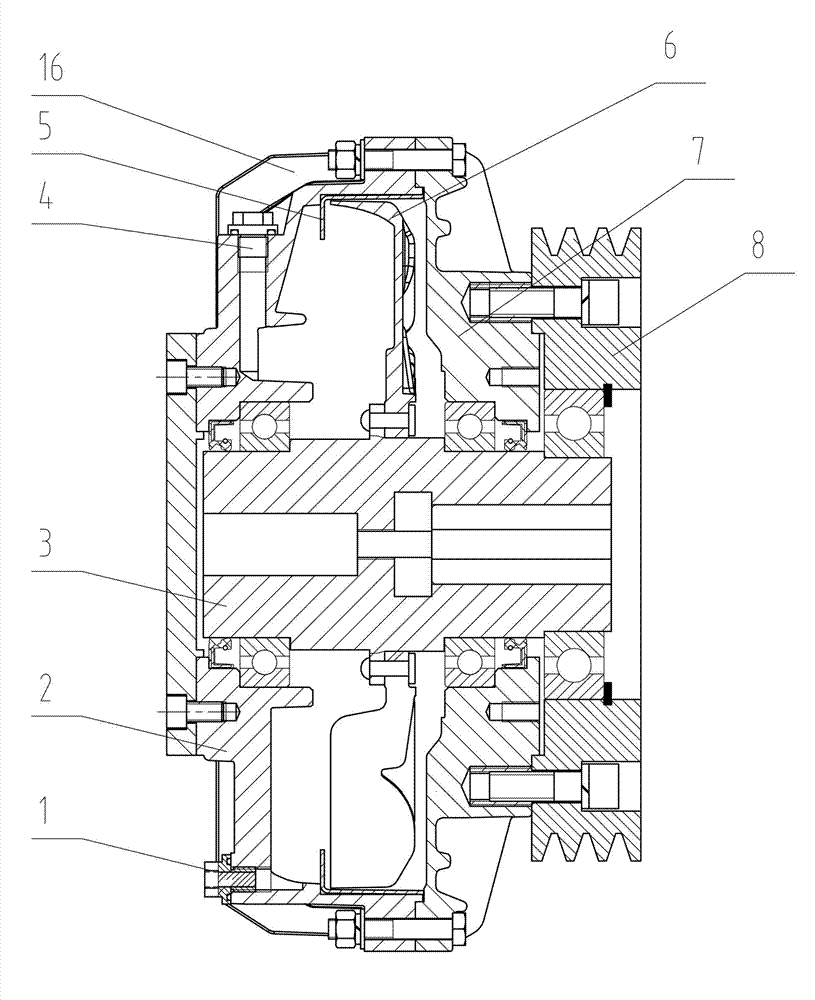

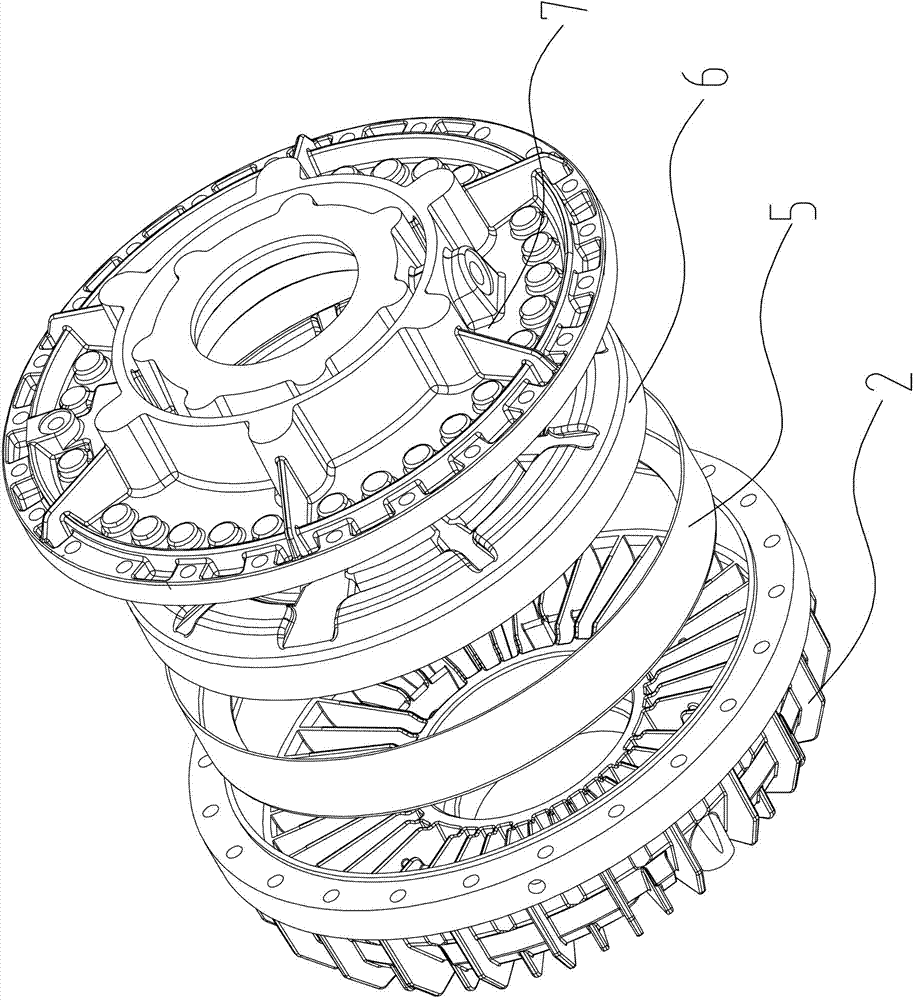

[0021] Depend on Figure 1 to Figure 11 It can be seen that the present invention includes a casing 7, a pump wheel 2 fixedly connected with the casing 7 and a turbine 6 corresponding to the pump wheel 2, the casing 7 is provided with an input pulley 8, the turbine 6 is fixedly connected with the output shaft 3, the input pulley 8, the casing 7 and the pump wheel 2 are connected as a whole, and the three are arranged on the output shaft 3 through bearings, which are characterized in that:

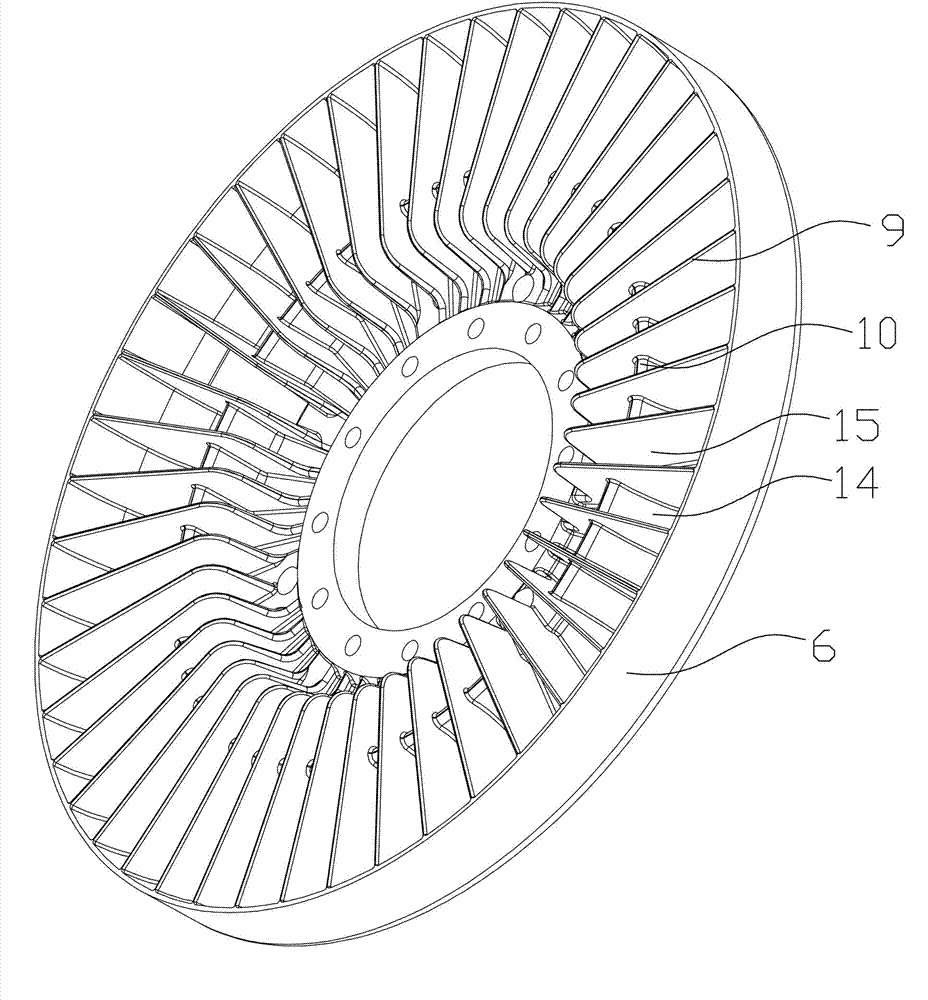

[0022] The inner side of the pump wheel 2 is a concave cavity, in which guide vanes 9 are arranged, and the inner cavity of the turbine 6 is also provided with guide vanes 9, and the turbine 6 is arranged in the concave cavity of the pump wheel 2, and the guide vanes on the inside of the two 9 corresponds to the setting, and a guide ring 5 is set between the pump wheel 2 and the turbine 6;

[0023] The above-mentioned guide vanes 9 are arranged at intervals to form a flow channel, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com