Quick inserting type grounding terminal and grounding wire

A technology of grounding wire and grounding terminal, which is applied in the direction of connection, contact parts, connection contact materials, etc., can solve the problems of long power outage time, time-consuming operation, low efficiency, etc., and achieve the effect of short power outage time and time-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

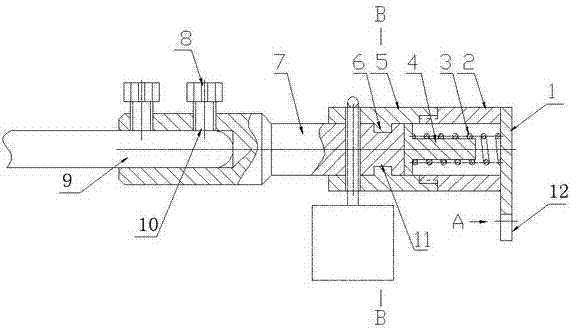

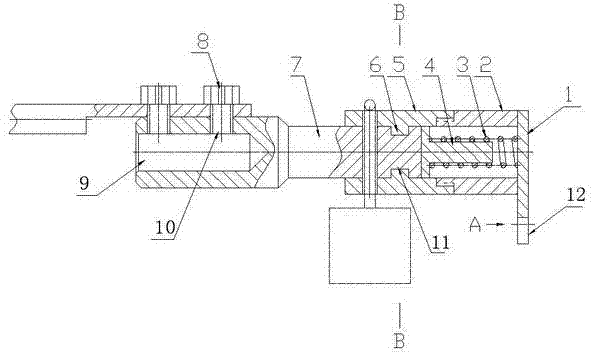

[0013] As shown in the figure, the quick plug-in ground terminal and the ground wire are composed of a socket and a plug 7 connected to the ground wire. The socket is mainly composed of a seat plate 1, a seat bottom 2 and a seat cap 5. Round tube shape, the seat plate 1 and the seat bottom 2 are welded together, the seat plate 1 has a fixing groove 12, the upper port of the seat bottom 2 has an external thread, and the lower port of the seat cap 5 has an outer thread that matches the upper port of the seat bottom 2 Screw thread, seat bottom 2 and seat cap 5 are threadedly connected, there is a symmetrical protrusion 6 in the middle of the inner wall of seat cap 5, and a "T"-shaped slider 4 is arranged in the lumen of the seat bottom 2, on which the "T"-shaped slider 4 The sleeve is equipped with a compression spring 3, and there is an annular slot 11 on the plug 7. The end of the plug 7 is a flat head, and the width of the flat head is smaller than the minimum distance between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com