Light-emitting diode (LED) constant current driving circuit and LED lamp

A technology of LED driving and constant current driving, applied in the field of circuits, can solve problems such as damage to circuit components, temperature rise of circuit components, fire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

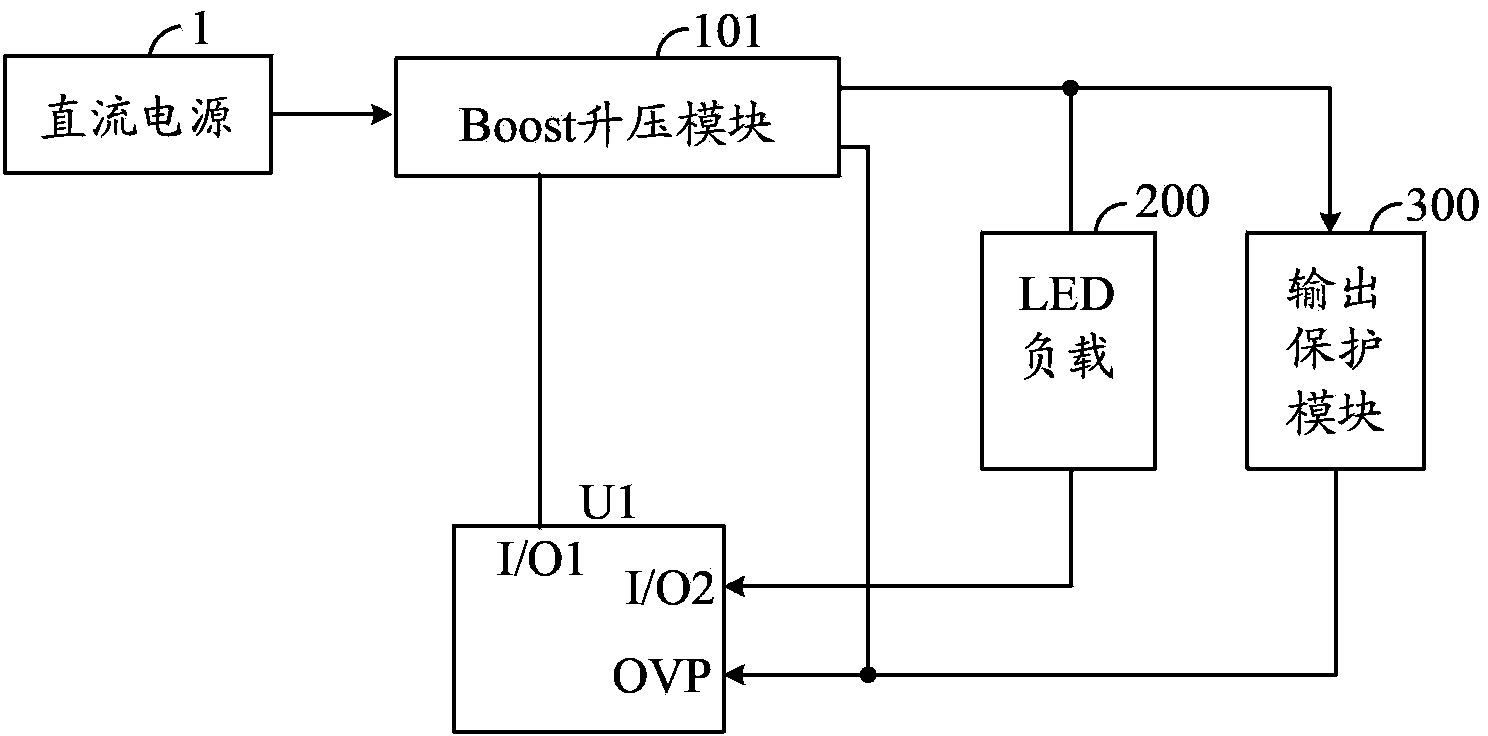

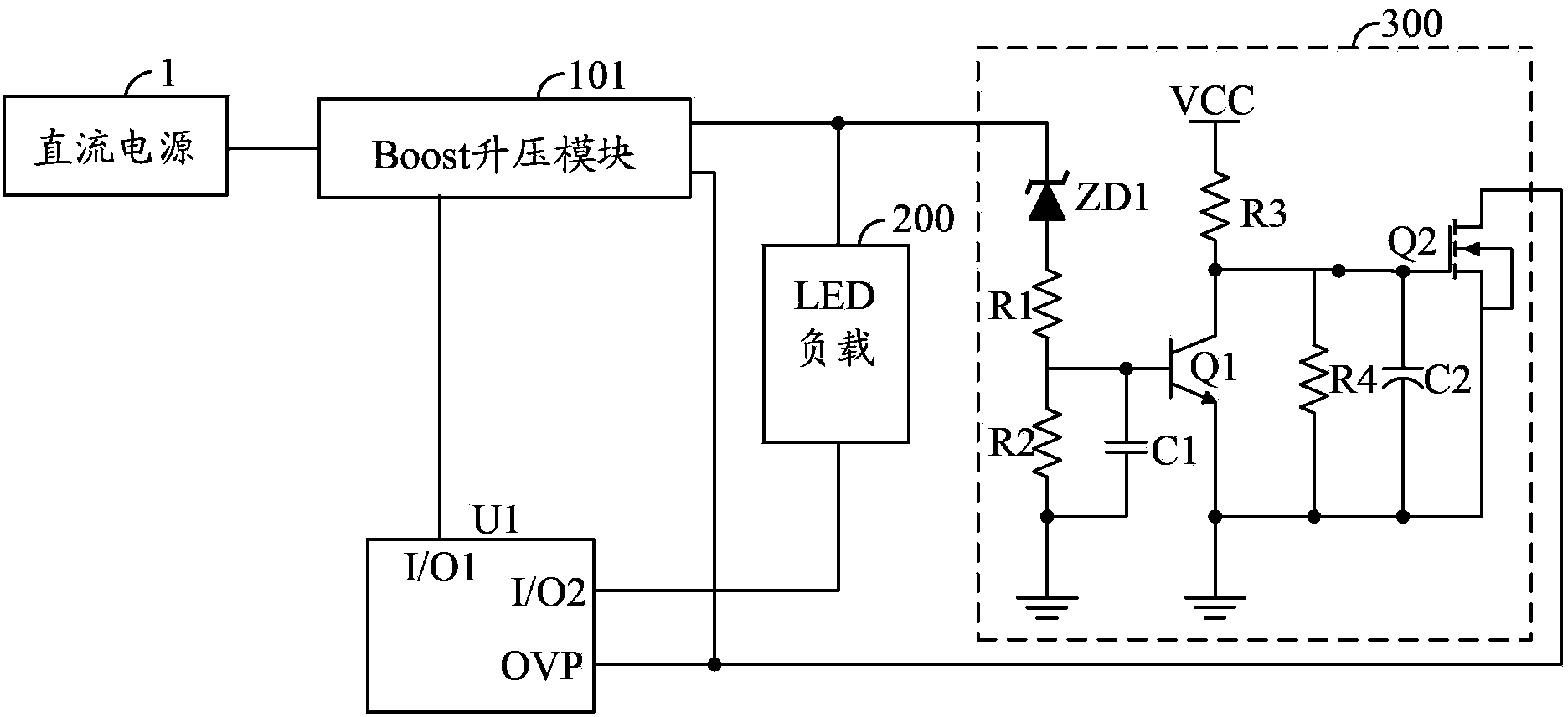

[0027] figure 2 The circuit structure of the LED constant current drive circuit provided by the first embodiment of the present invention is shown. For the convenience of explanation, only the parts related to the first embodiment of the present invention are shown, and the details are as follows:

[0028] As an embodiment of the present invention, the first switching tube 301 adopts an NPN transistor Q1, the base of the NPN transistor Q1 is the control terminal of the first switching tube 301, and the collector of the NPN transistor Q1 is the high potential of the first switching tube 301 terminal, the emitter of the NPN transistor Q1 is the low potential terminal of the first switch tube 301 .

[0029] As an embodiment of the present invention, the second switch tube 302 uses an N-type MOS tube Q2, the gate of the N-type MOS tube Q2 is the control terminal of the second switch tube 302, and the drain of the N-type MOS tube Q2 is the gate of the second switch tube 302. The ...

Embodiment 2

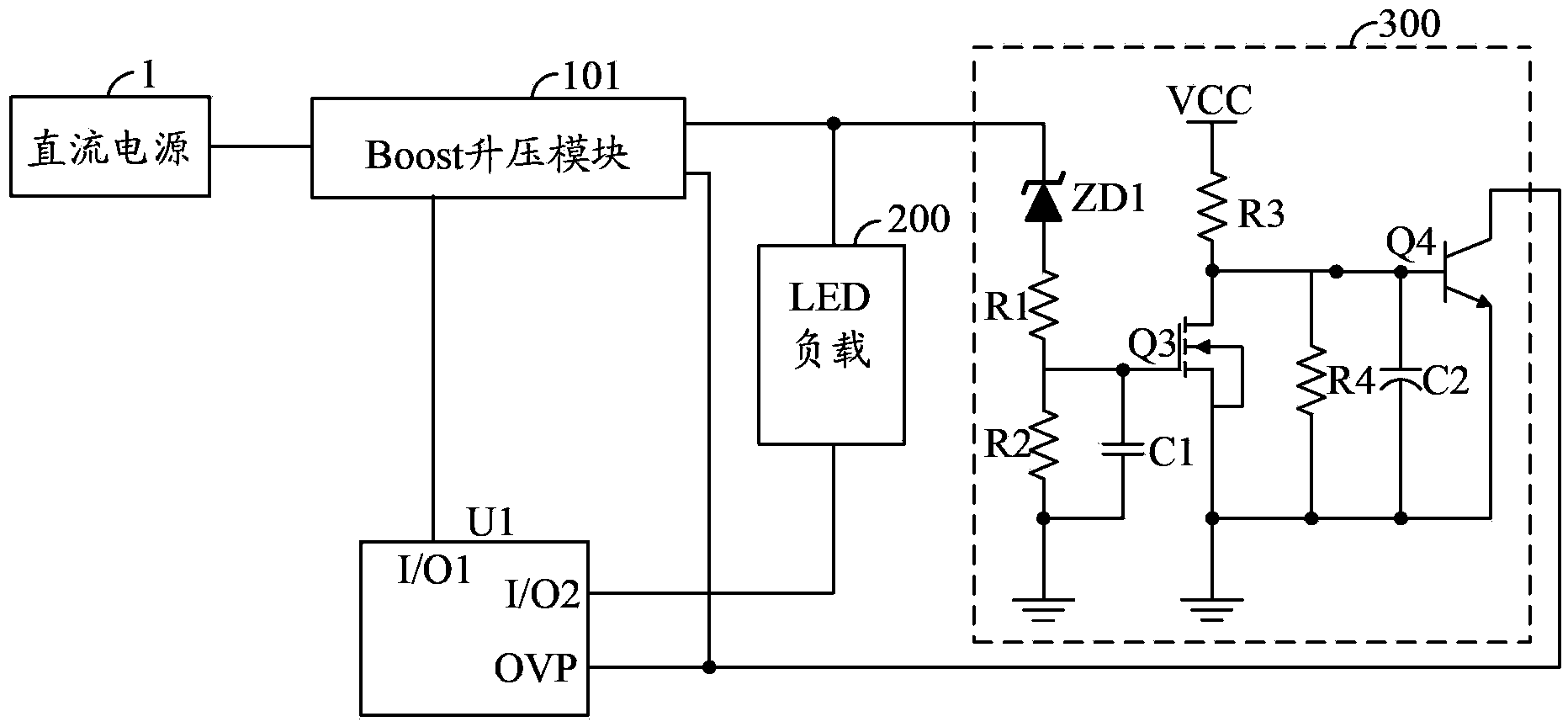

[0033] image 3 The circuit structure of the LED constant current drive circuit provided by the second embodiment of the present invention is shown. For the convenience of explanation, only the parts related to the second embodiment of the present invention are shown, and the details are as follows:

[0034] As an embodiment of the present invention, the first switch tube 301 uses an N-type MOS tube Q3, the gate of the N-type MOS tube Q3 is the control terminal of the first switch tube 301, and the drain of the N-type MOS tube Q3 is the gate of the first switch tube 301. At the high potential end, the source of the N-type MOS transistor Q3 is the low potential end of the first switch transistor 301 .

[0035]As an embodiment of the present invention, the second switch tube 302 uses an NPN transistor Q4, the base of the NPN transistor Q4 is the control terminal of the second switch tube 302, and the collector of the NPN transistor Q4 is the high potential of the second switch t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com