Screening device

A sieving device and sieving technology, applied in the direction of sieving, solid separation, grille, etc., can solve the problems of increasing the burden on operators, reducing the operating efficiency of sieving machines, and limited sieve specifications, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

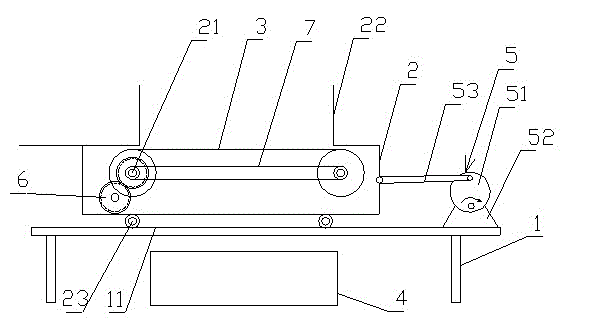

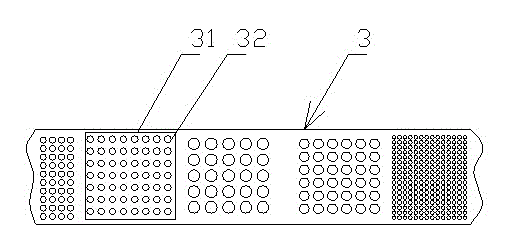

[0014] The screening device includes a base 1, a screening frame 2, a screening coil 3, a receiving bucket 4 and a reciprocating drive mechanism 5. The screening frame 2 is slidably arranged on the base, and the middle part of the screening frame 2 is empty. There is a rotating shaft 21 at each end, and the two ends of the screening coil 3 are respectively wound on the rotating shafts 21 at both ends of the screen moving frame. There are several sieving areas 31 distributed on the top, and a plurality of sieve holes 311 of a certain specification are arranged in the sieving area 31. The reciprocating drive mechanism 5 is connected with the sieve moving frame 2, so that the sieve moving frame 2 slides reciprocally on the base 1, receiving The bucket 4 is arranged on the lower part of the sieving frame 2 and is opposite to the screening area on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com