Multi-paper-path double-face digital printing system and digital rotary press

A digital printing and paper path technology, applied in the field of multi-paper path double-sided digital printing system and digital rotary printing machine, can solve the problems of large volume, waste of investment, high cost of equipment transformation, etc., and achieve good integration and operability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

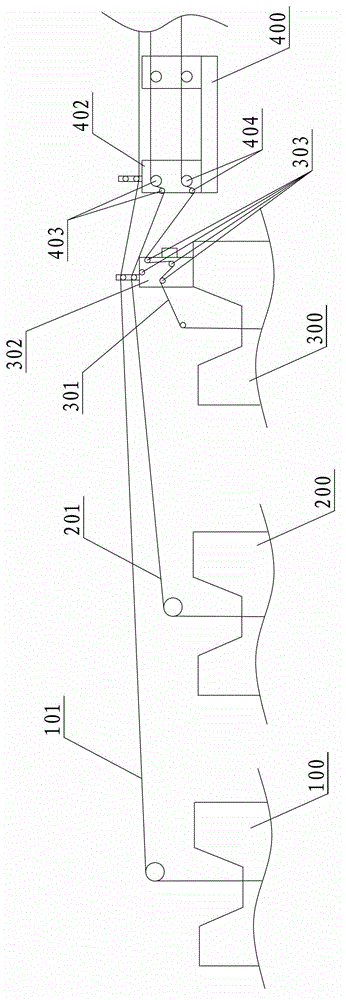

[0030] The invention provides a double-sided digital printing system with multiple paper paths. By utilizing the existing space of the traditional rotary printing machine and directly installing it, the traditional rotary printing machine can be transformed and upgraded into a double-sided digital printing system capable of front / reverse paper printing. Surface digital printing equipment.

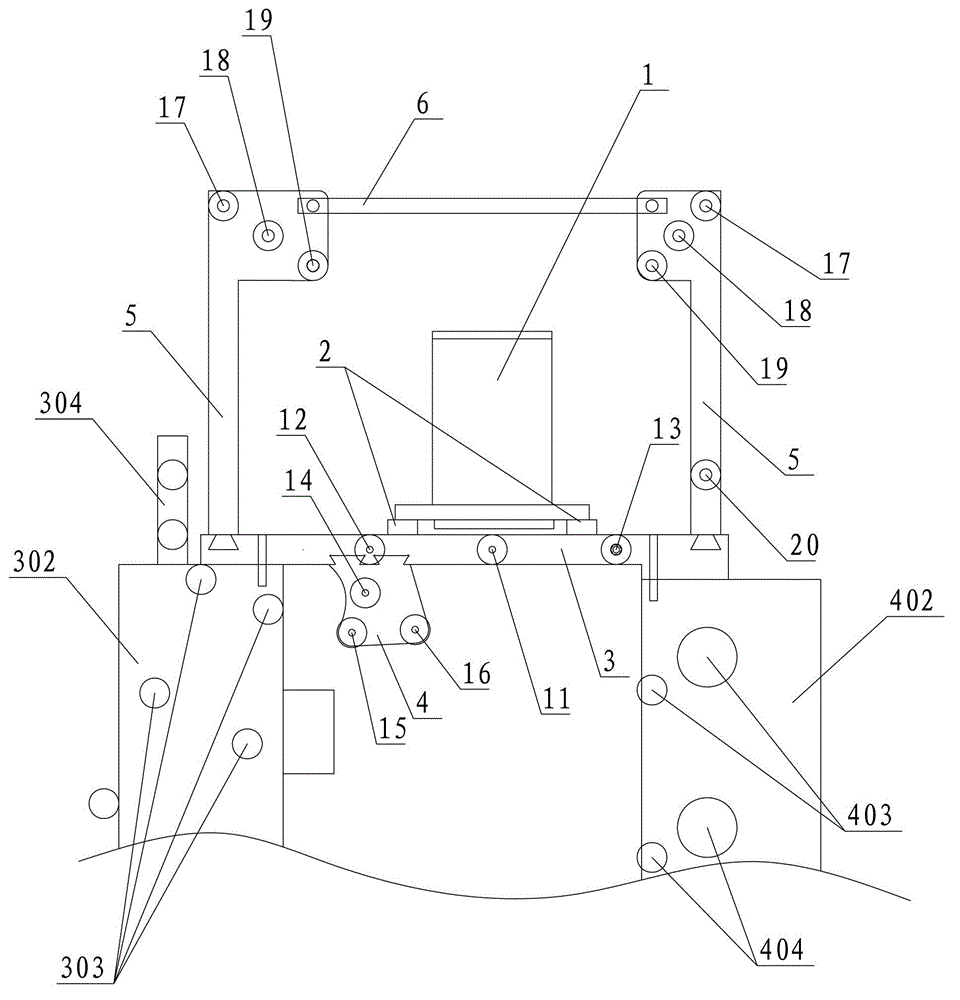

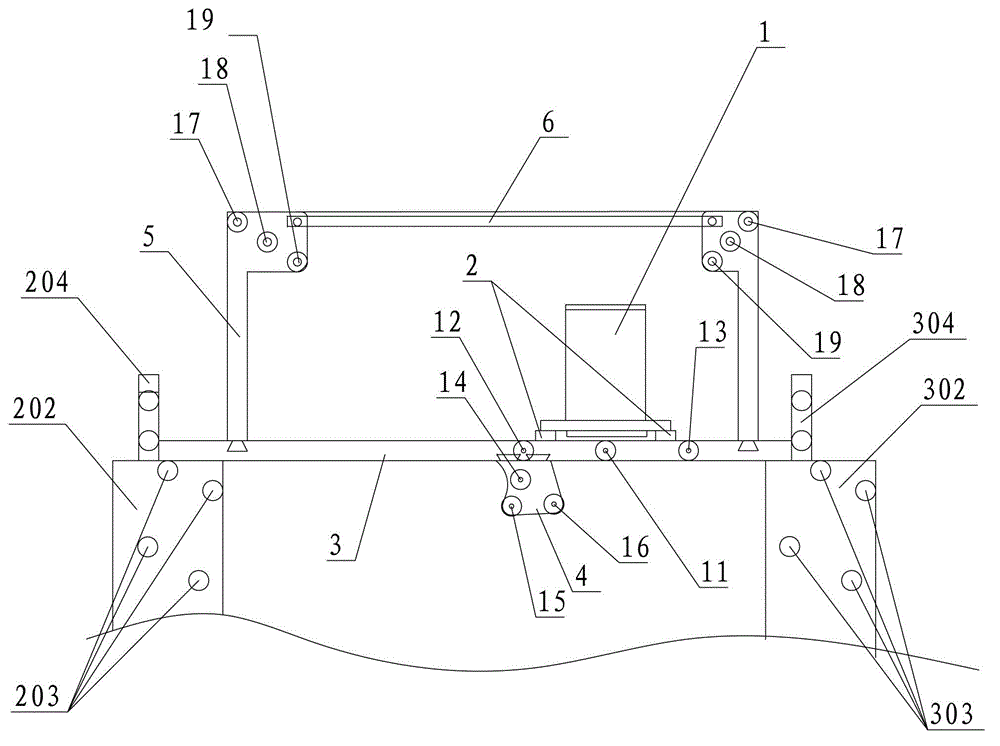

[0031] Specifically, in order to realize simultaneous printing on both sides of the paper path, the multi-paper path double-sided digital printing system of the present invention is equipped with two sets of digital printing mechanisms, see figure 2 , 3 , each digital printing mechanism includes a digital printing head 1, a main frame, a printing paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com