Laminating machine having four paper feeding stations

A paper feeding and station technology, applied in pasting, transportation and packaging, decorative arts, etc., can solve the problems of slow paper mounting and increase control difficulty, and achieve the effect of simplifying the structure, improving the mounting speed, and reducing the longitudinal length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

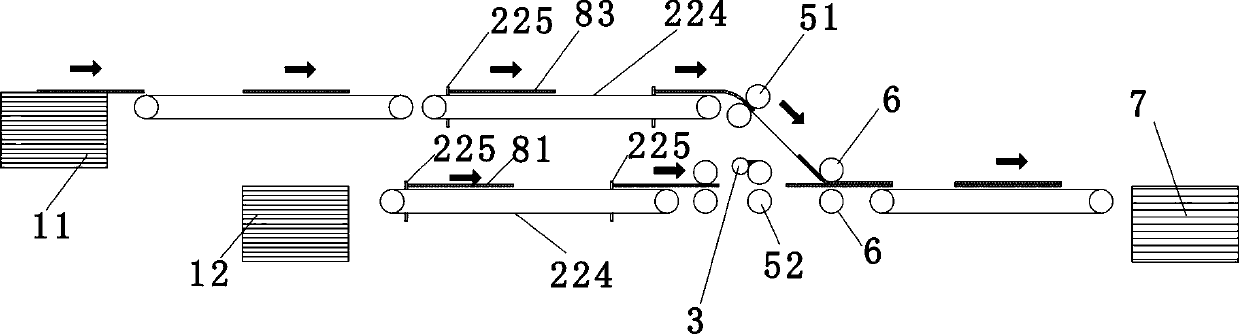

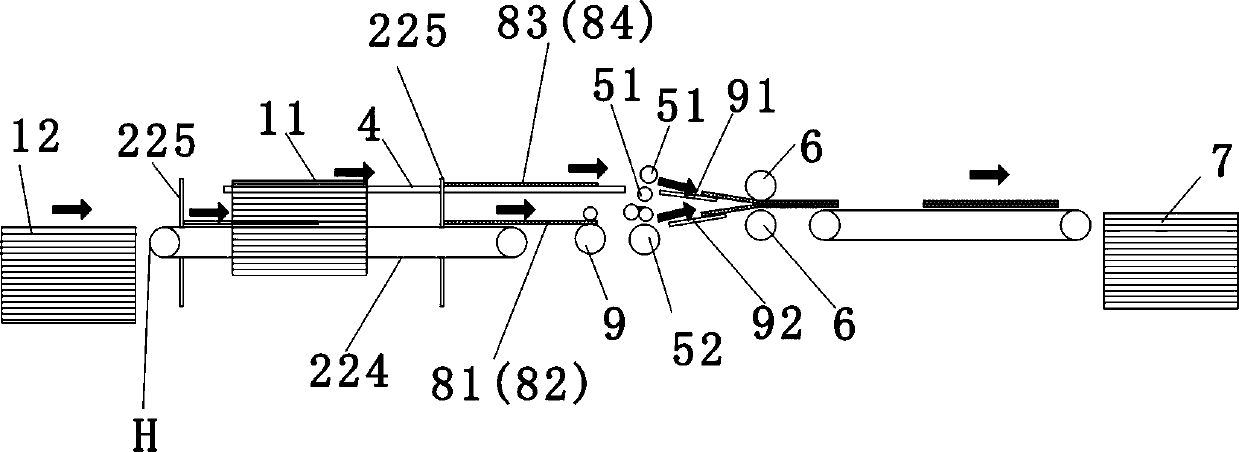

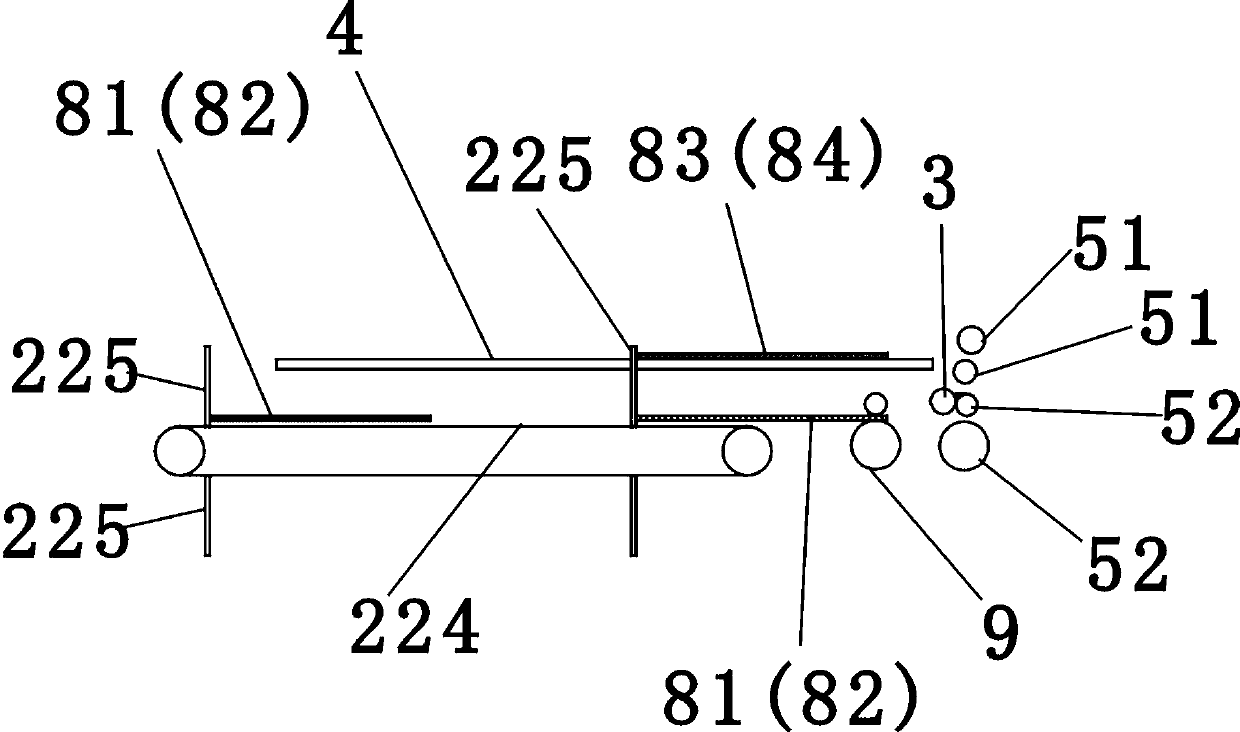

[0027] figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 As shown, the laminating machine of the four paper feeding stations includes an upper paper feeding station 11, a lower paper feeding station 12, an upper paper feeding mechanism, a lower paper feeding mechanism, an upper rubber roller 3, an upper pinch feeding mechanism, a lower layer Pinching mechanism, laminating mechanism, paper delivery mechanism 7, the pinching mechanism of the upper layer is provided with two pinch rollers 51, and the pinching mechanism of the lower layer is also provided with two nip rollers 52, and the laminating mechanism is provided with two pressure rollers 6; The paper feeding station 12 is located behind the lower paper feeding mechanism, the lower paper feeding mechanism is located behind the lower pinch mechanism, the upper rubber roller 3 is close to the lower pinch mechanism, the upper paper feeding mechanism is located behind the upper pinch mechanism, and the upper pinch Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com