Diaphragm unwinding mechanism and diaphragm unwinding method

A technology of unwinding mechanism and diaphragm, which is applied in the direction of structural parts, final product manufacturing, battery pack components, etc. It can solve problems such as diaphragm damage, diaphragm tension cannot be controlled, and lamination speed cannot meet the needs of ultra-high-speed lamination, etc., to achieve Reduce the unwinding speed, meet the needs of high-speed lamination, and facilitate the effect of tension adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments and features in the embodiments of the present invention can be combined with each other.

[0026] The present invention will be described in detail below with reference to the drawings and in combination with embodiments.

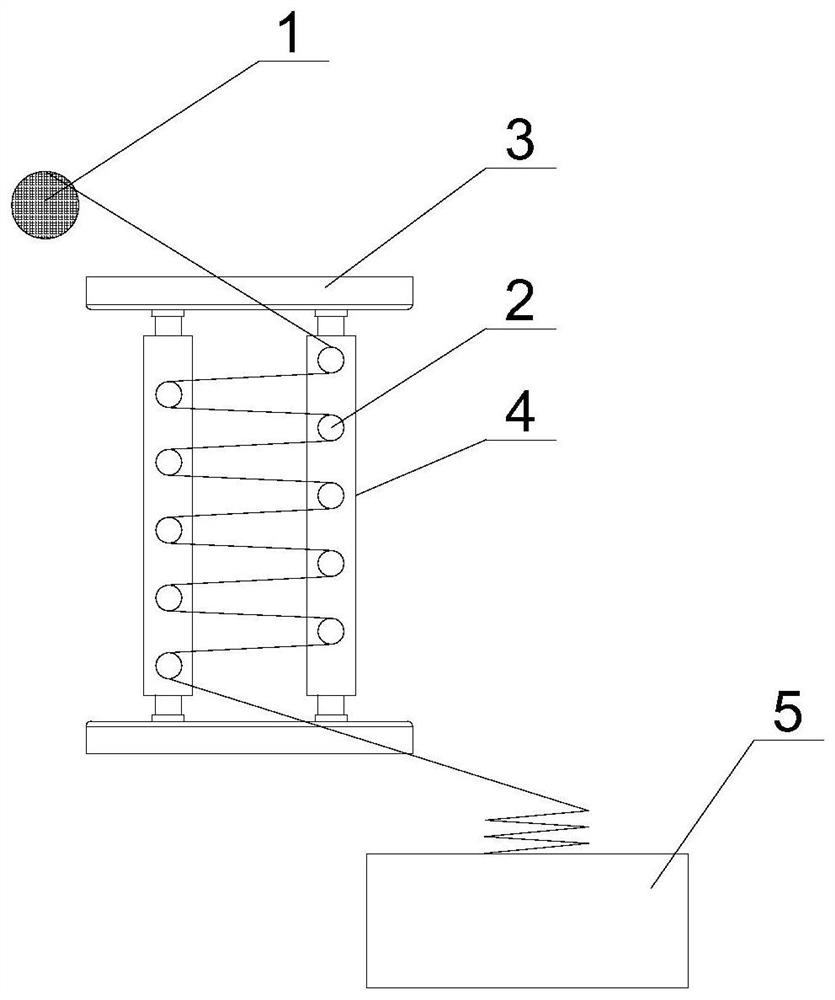

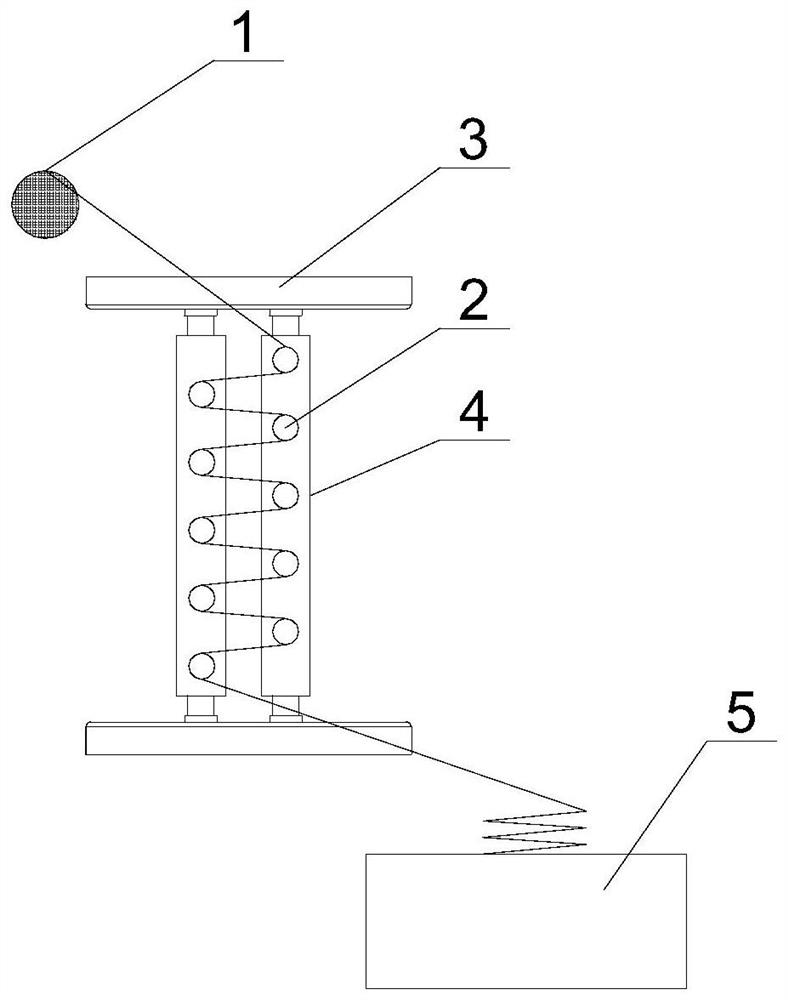

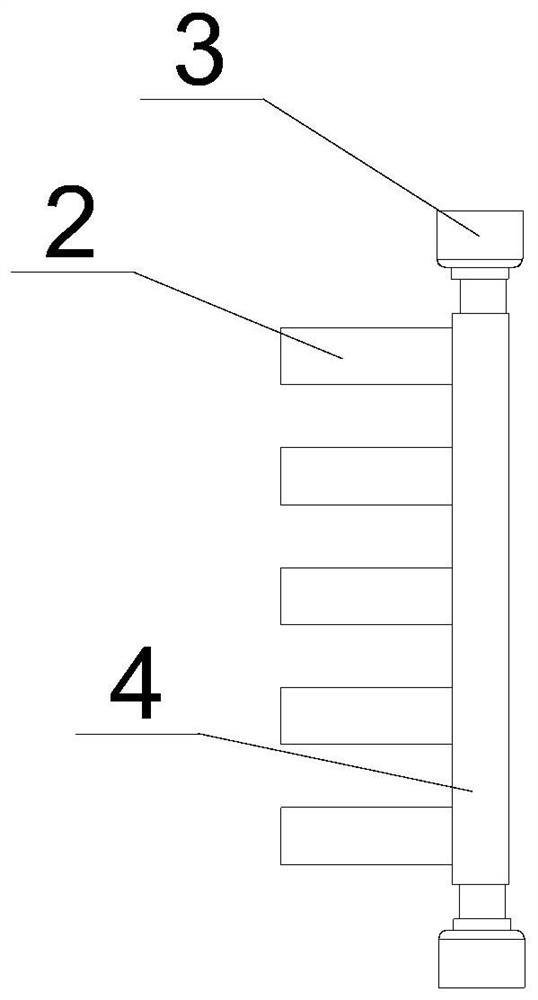

[0027] combine Figure 1-Figure 3 According to one aspect of the present invention, a diaphragm unwinding mechanism is provided, which includes a diaphragm roll 1 and two sets of rollers arranged in parallel and capable of moving toward each other, each set of rollers includes rollers 2 arranged at intervals along the vertical direction, The rollers 2 of the two groups of rollers are arranged to be continuously and alternately wound with the diaphragm released from the diaphragm roll 1 .

[0028] It should be noted that the diaphragm is wound on the rotating roller to form the diaphragm roll 1, so the diaphragm roll 1 can release the diaphragm during the rotation process, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com