Special bracket for connecting rod

A technology of connecting rod and sub-frame, which is applied to suspension, elastic suspension, transportation and packaging, etc., can solve the problems of insufficient fixation and structural limitations, and achieve the effects of low cost, improved service life and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

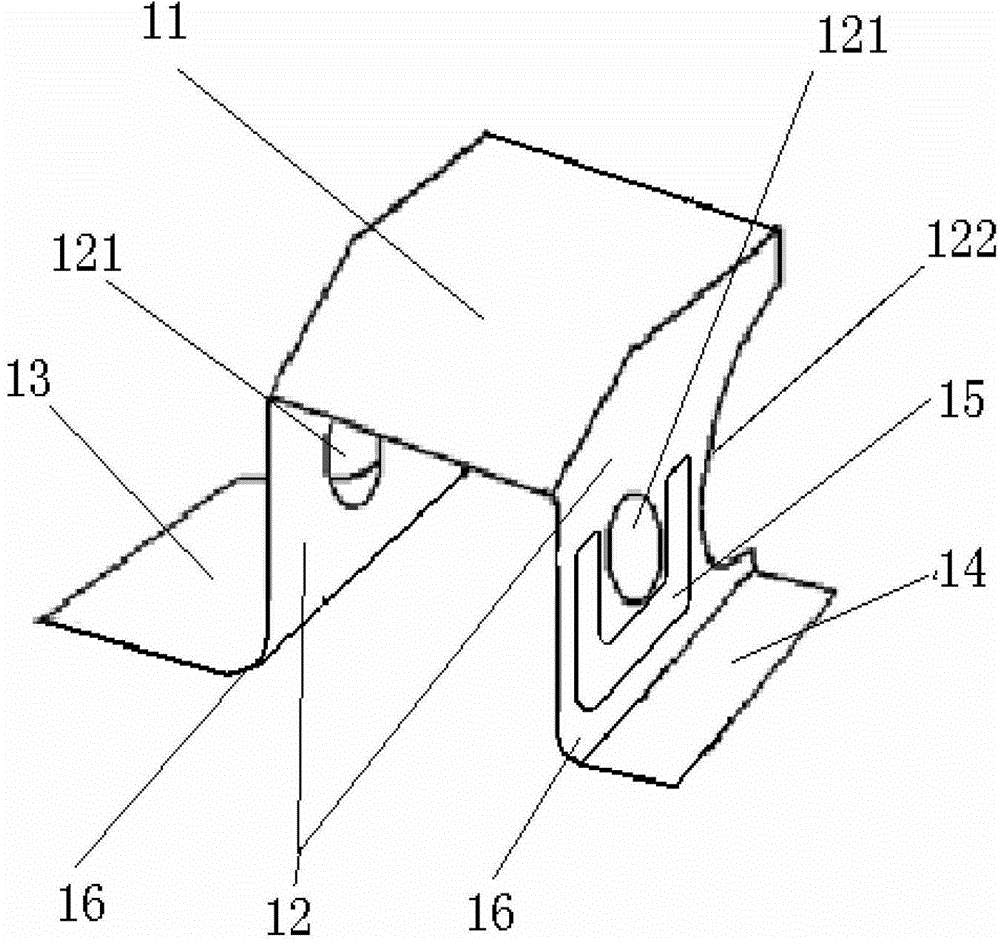

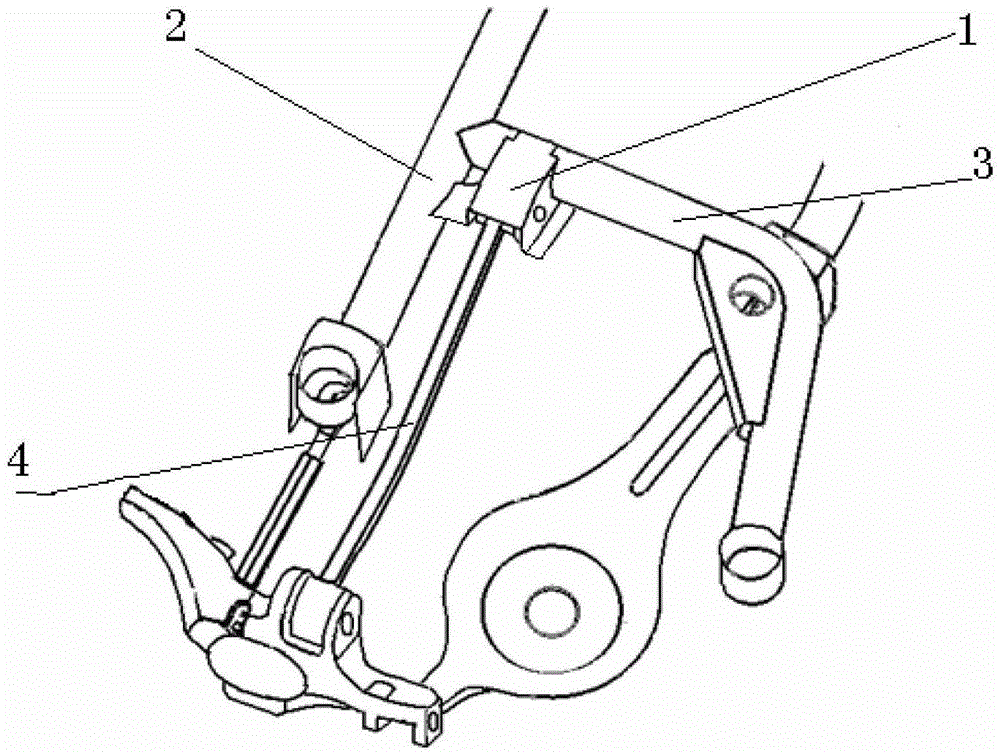

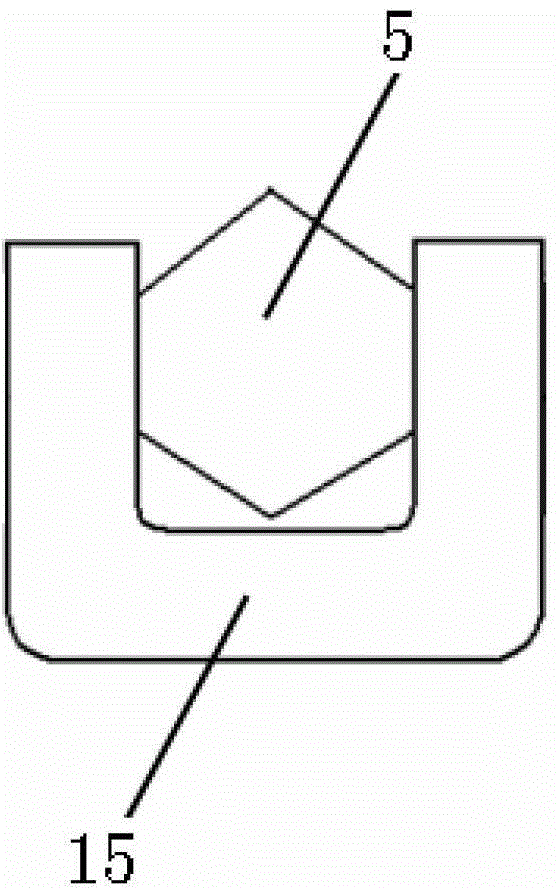

[0033] like figure 1 shown, see also figure 2 , a special bracket 1 for connecting rod 4 provided by the embodiment of the present invention is used to connect with the sub-frame of an automobile. profile, the first flanging 13 and the second flanging 14, the first flanging 13 and the second flanging 14 are respectively arranged on the two sides 12 of the inverted U-shaped part, and the first flanging 13 and the second flange 14 are respectively inclined to the outside of the inverted U-shaped piece, the first flange 13 is used for fixed connection with the beam 2, and the rear part of the top surface 11 of the inverted U-shaped piece The edges, the rear edges of the two sides 12 of the inverted U-shaped member and the rear edges of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com