Method and tool for lifting electrolysis cathode plate and electrolysis anode plate

A cathode and anode, anode plate technology, applied in the electrolysis process, electrolysis components, transportation and packaging, etc., can solve the problems of shallow bow of the anode plate, not suitable for lifting the plate by the conveyor belt, etc., to achieve increased adaptability, reliable lifting, Effects suitable for promotional applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

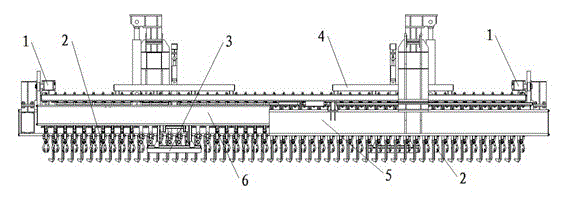

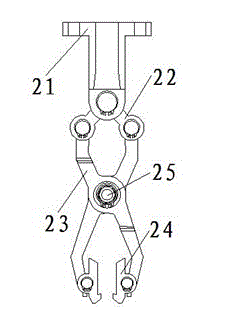

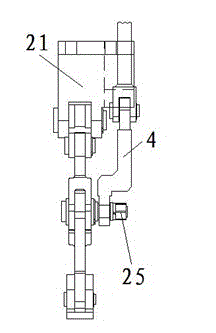

[0024] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the description of the embodiments. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention. For Those of ordinary skill in the art can also obtain other drawings based on these drawings without making creative efforts.

[0025] A method for hoisting cathode and anode plates for electrolysis, a method for hoisting cathode and anode plates for electrolysis, using a crane to lower and lift the sling, when the large and small cranes run above the pole plates at each position, the crane trolley moves to lower the entire sling ; When the whole sling is close to the working position, the cathode clamp of the sling is about 500mm away from the upper conductive rod of the cathode and anode plates, and the cathode beam frame moves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com