Reversing valve of hydraulic piston pump

A technology of hydraulic piston and reversing valve, which is applied to pump components, variable displacement pump components, and components of pumping devices for elastic fluids, etc., can solve the problem of low efficiency and low pumping efficiency of beam pumping units. and other problems, to achieve the effect of simple processing, improving processing accuracy and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

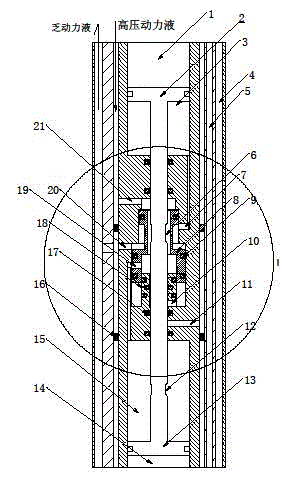

[0028] The present invention is described below in conjunction with the accompanying drawings.

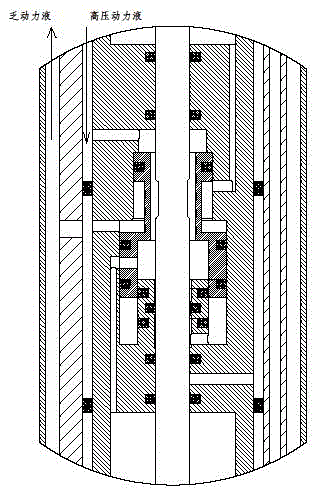

[0029] attached figure 1 It is a schematic diagram of the reversing valve structure of a commonly used hydraulic piston pump. The E-type hydraulic piston pump of the American KEBO company adopts this structure. The only domestic manufacturer of hydraulic piston pumps is the hydraulic piston pump produced by Shengli Oilfield Rodless Pump Co., Ltd. Reversing valves are of this type. In the prior art, the mutually moving parts in its structure are separated by gaps. The structure of the present invention is different from the prior art in that, figure 1 In the structure shown, there are step seals or lattice circles, that is, the parts represented by small black squares, between the parts that move with each other.

[0030] The working principle of the present invention is: when the reversing valve 8 is at the upper limit position, the high-pressure power fluid enters the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com