Fiber reinforced polymer (FRP) tendon and stainless steel tube composite and preparation technology thereof

A technology of stainless steel pipe and preparation process, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of high cost and large thickness of stainless steel pipes, and achieve the effect of reducing wall thickness, material weight, and material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

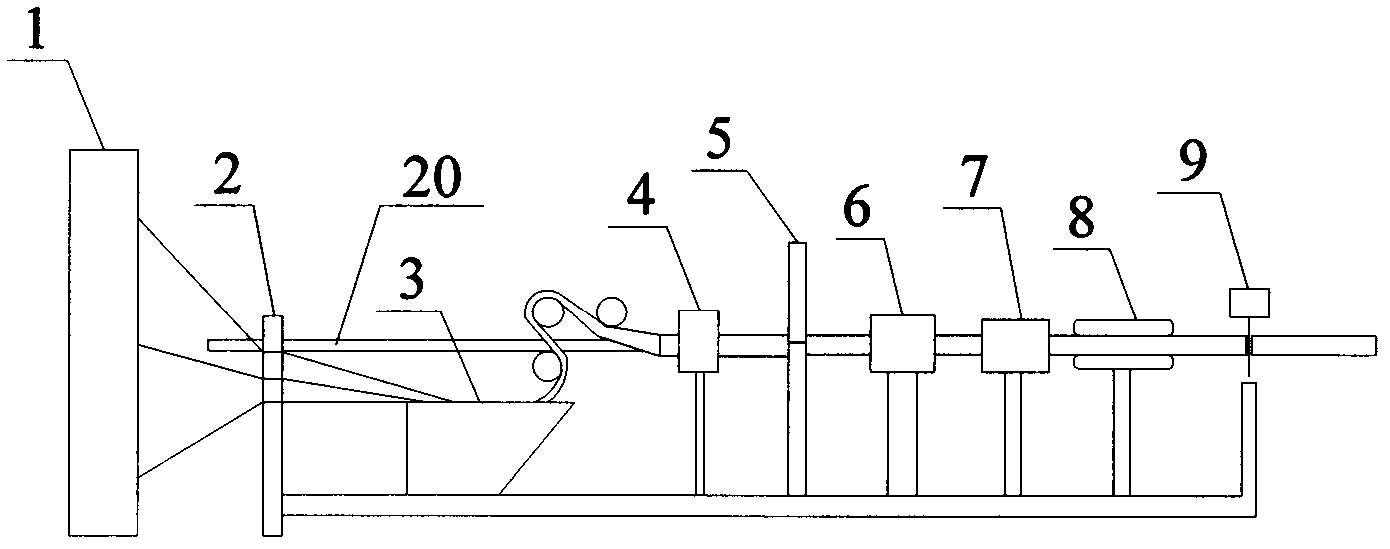

[0021] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] FRP is the abbreviation of Fiber Reinforced polymer (fiber reinforced material).

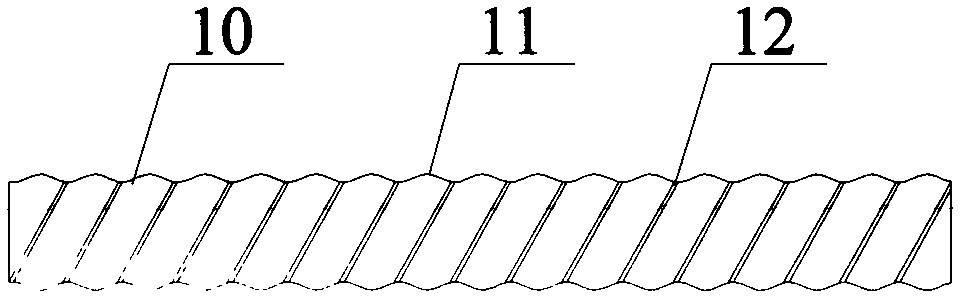

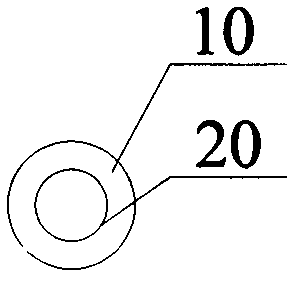

[0023] Such as figure 1 with figure 2 As shown, the present invention provides a FRP bar composite stainless steel pipe, including a stainless steel pipe 20, an FRP bar 10 fastened on the outer surface of the stainless steel tube 20, and the FRP bar 10 includes a raised portion 11 and a threaded portion 12, The threaded portion 12 is continuously distributed on the FRP rib 10 . Under the condition of ensuring various performance indexes of the FRP-reinforced composite stainless steel pipe, the wall thickness of the stainless steel pipe 20 can be effectively reduced, material cost and material weight can be reduced; and the use of the FRP rebar 10 meets the development needs of a green and resource-saving society.

[0024] The thread...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap