Vehicle seat

A technology for vehicle seats and seats, which is applied to vehicle seats, seat frames, vehicle parts, etc., can solve problems such as flange deformation and the inability of loads to be effectively carried.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

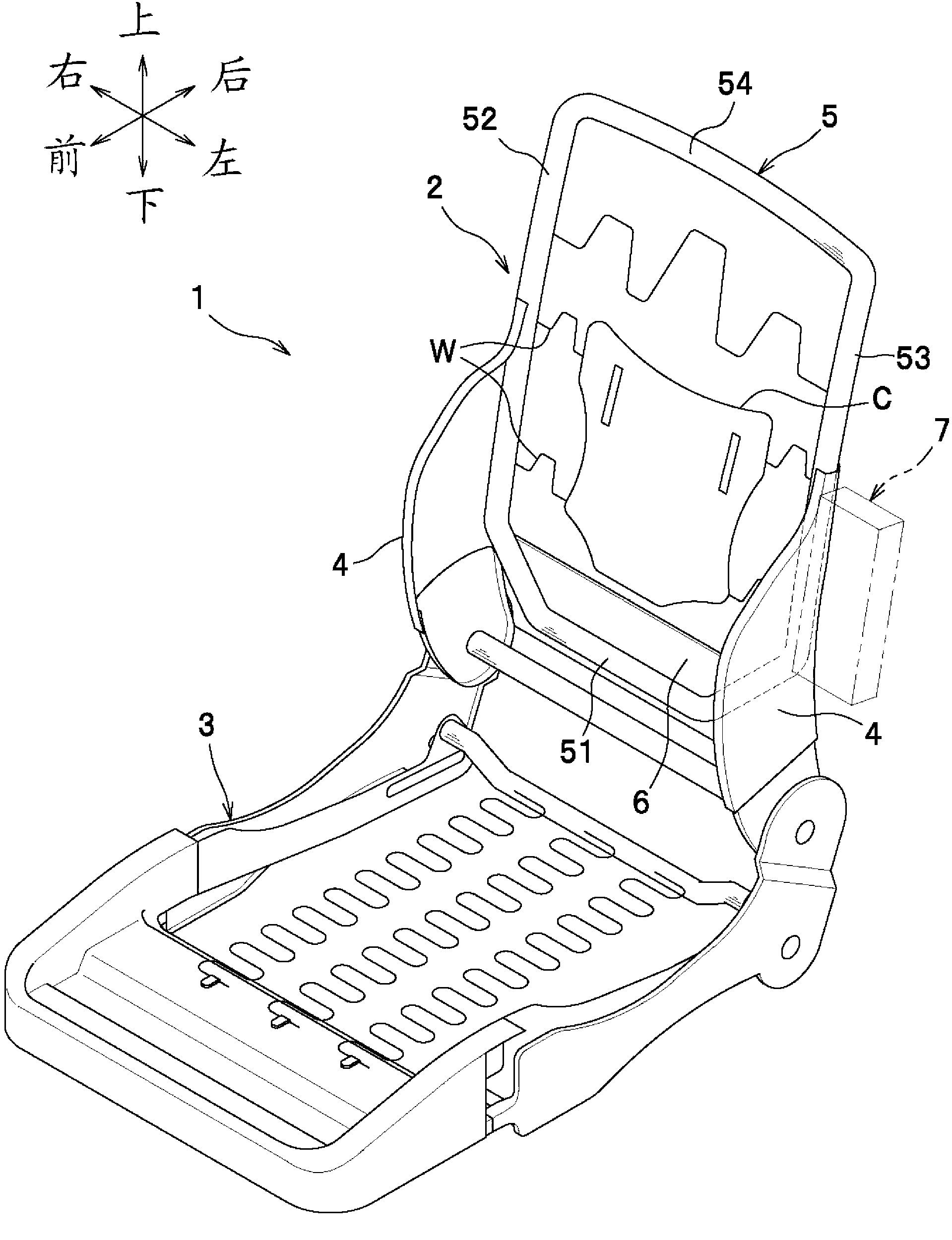

[0068] Next, a specific implementation manner (first embodiment) of the present invention will be described in detail with reference to the accompanying drawings.

[0069] According to the present embodiment, the vehicle seat is composed of such as figure 1 The shown seat frame 1 is formed of a seat frame 1 covered on the outside with a seat cushion made of polyurethane foam or similar material. The seat frame 1 includes a seat back frame 2 and a seat bottom frame 3 . It is not difficult to understand that in the description of the present invention, the front / rear, left / right and up / down directions are stipulated as taking the view angle of the occupant sitting on the seat as the criterion.

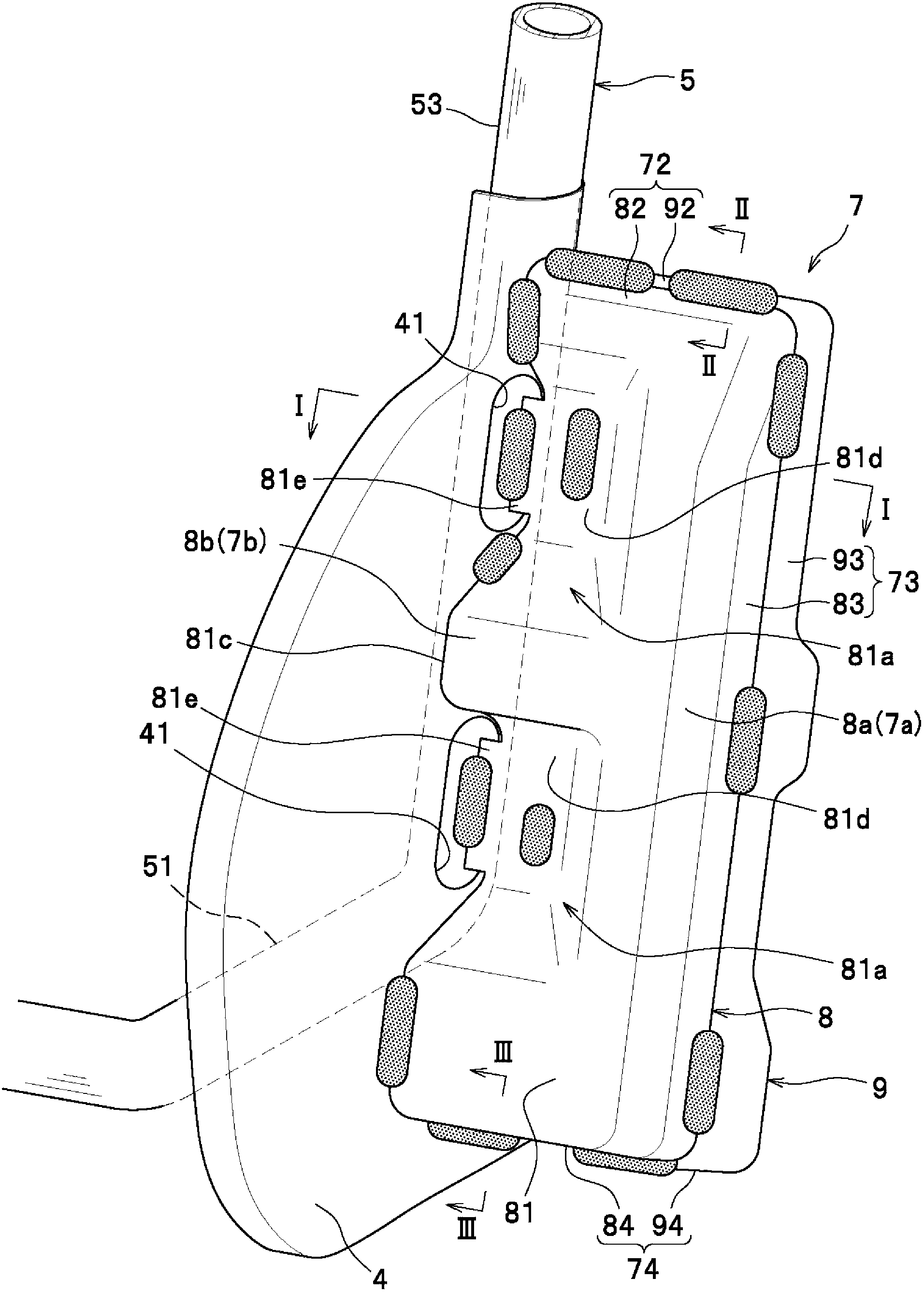

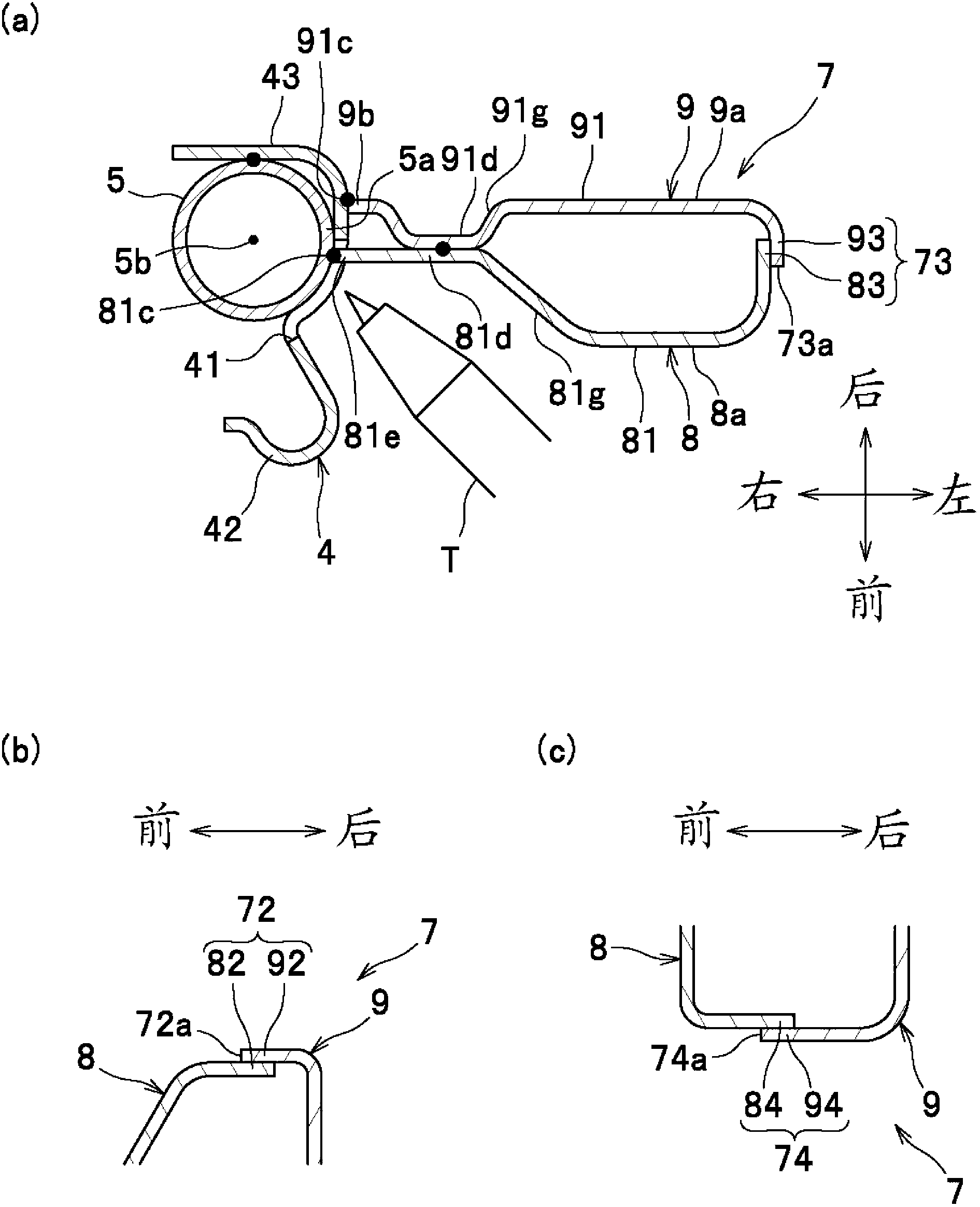

[0070] The seat back frame 2 includes a pair of side frames 4 , a pipe frame 5 as an example of a reinforcing frame (inner frame) for reinforcing the side frames 4 , a bottom frame 6 , and a bracket 7 as an example of a force receiving member.

[0071] The side frame 4 is a plate-like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com