Scaffold type lens collar punching die of tablet personal computer

A tablet computer bracket and lens ring technology, applied in the field of stamping dies, can solve problems such as increased production costs, low molding efficiency, waste of resources, etc., and achieve the effects of increasing yield, increasing production efficiency, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

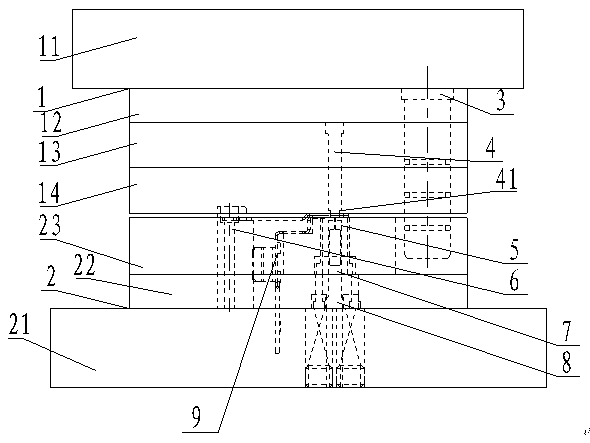

[0010] see figure 1 , the embodiment of the present invention includes:

[0011] A tablet computer support type lens ring stamping die, the tablet computer support type lens ring stamping die includes an upper die 1 and a lower die 2 positioned and engaged with each other through a guide column 3 fixed to the upper die 1; the upper die includes an upper backing plate 12. The punch fixing plate 13 and the unloading plate 14 are successively stacked and fixed on the upper template 11 through pins and screws. The punch fixing plate 13 is equipped with a punching punch 4 with a flanging forming table 41; the lower A lower die 5 with a positioning device 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com