Molten glass cluster shunting mechanism

A shunt mechanism and a technology for melting glass, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of glass mass hitting the edge of the shunt tank, poor working stability of the cylinder, and insufficient advance of the shunt tank, etc., to achieve simple structure and stable operation. , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

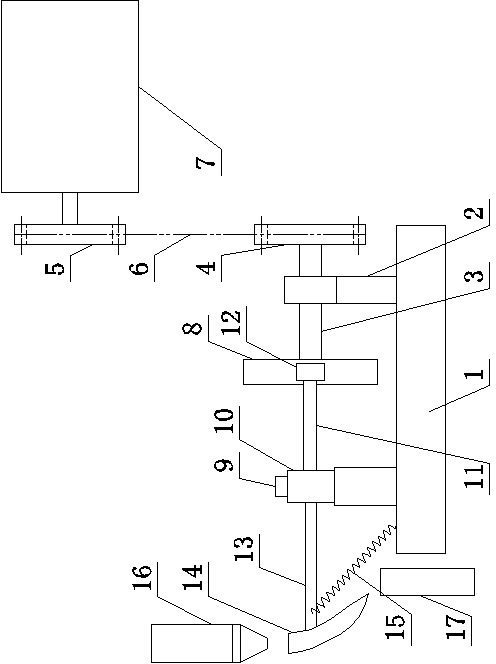

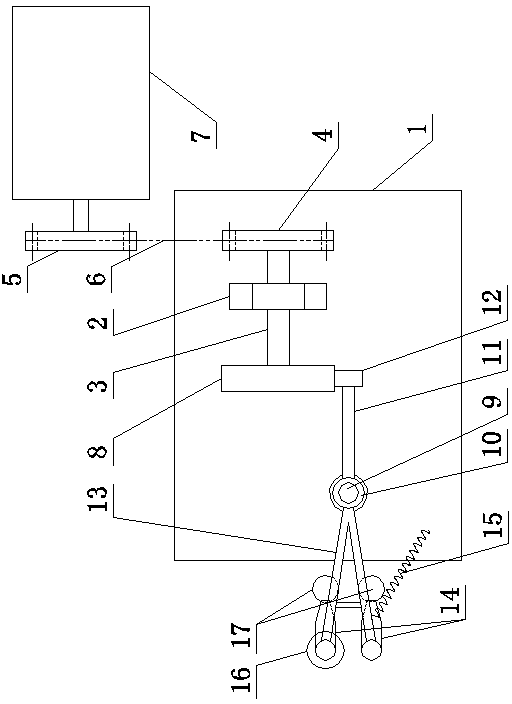

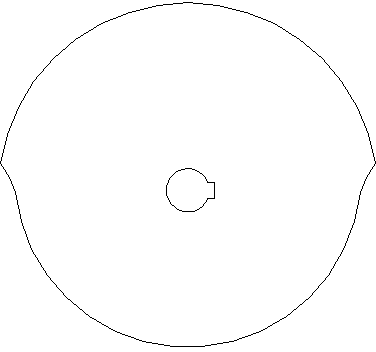

[0014] Such as figure 1 , figure 2 and image 3 The shown molten glass mass diversion mechanism includes a splitter base 1 and a vertical splitter shaft 9 on the splitter base 1, a bearing seat and a bearing 2, and a horizontally arranged transmission is installed on the bearing inner ring of the bearing seat and the bearing 2. Axis 3. One end of the transmission shaft 3 near the vertical distribution shaft 9 is provided with a diverter cam 8, and the other end of the transmission shaft 3 is connected with the driving mechanism. The driving mechanism includes a motor 7, a driving sprocket 5 and a driven sprocket 4, and the driving sprocket 5 Installed on the output end of the motor 7, the driven sprocket 4 is installed on the transmission shaft 3, and the driving sprocket 5 and the driven sprocket 4 are connected through a chain 6 transmission. A sleeve 10 is sleeved on the vertical diverter shaft 9, and a toggle rod 11 and a diverter frame 13 are arranged on the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com