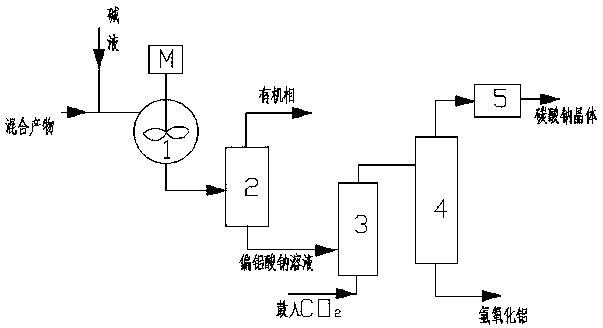

Alkali treatment method and treatment device for spent aluminum isopropoxide catalyst

A technology of aluminum isopropoxide and waste catalyst, which is applied in chemical instruments and methods, aluminum compounds, alkali metal aluminate/aluminum oxide/aluminum hydroxide preparation, etc., which can solve the loss of useful substances, large odor, and multiple Solve problems such as solid alumina residues, achieve the effect of increasing recycling benefits and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 50g of the mixed product and 200g of 5% sodium hydroxide solution, mix and stir, stir evenly and then let stand to separate layers, the quality of the upper oil phase is 40g, and the lower water phase is 208g. The lower aqueous phase was treated with CO 2 The precipitate obtained after neutralization was washed and dried to obtain 9.57 g of aluminum hydroxide powder.

Embodiment 2

[0030] Take 50g of the mixed product and 100g of 10% sodium hydroxide solution, mix and stir, stir evenly, and then stand for layering. The mass of the upper oil phase is 40g, and the lower layer of water phase is 109g. The precipitate obtained after the lower aqueous phase was neutralized by CO2 was washed and dried to obtain 9.52 g of aluminum hydroxide powder.

Embodiment 3

[0032] Take 50g of the mixed product and 50g of 20% sodium hydroxide solution, mix and stir, stir evenly and then let stand to separate layers, the mass of the upper oil phase is 39g, and the lower layer of water phase is 60g. The precipitate obtained after the lower aqueous phase was neutralized by CO2 was washed and dried to obtain 9.55 g of aluminum hydroxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com