Method and device for producing enhanced hollow fiber membrane

A production method and fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as blockage, inner diameter of permeable membrane filaments, etc., to improve bonding force, bond strength, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

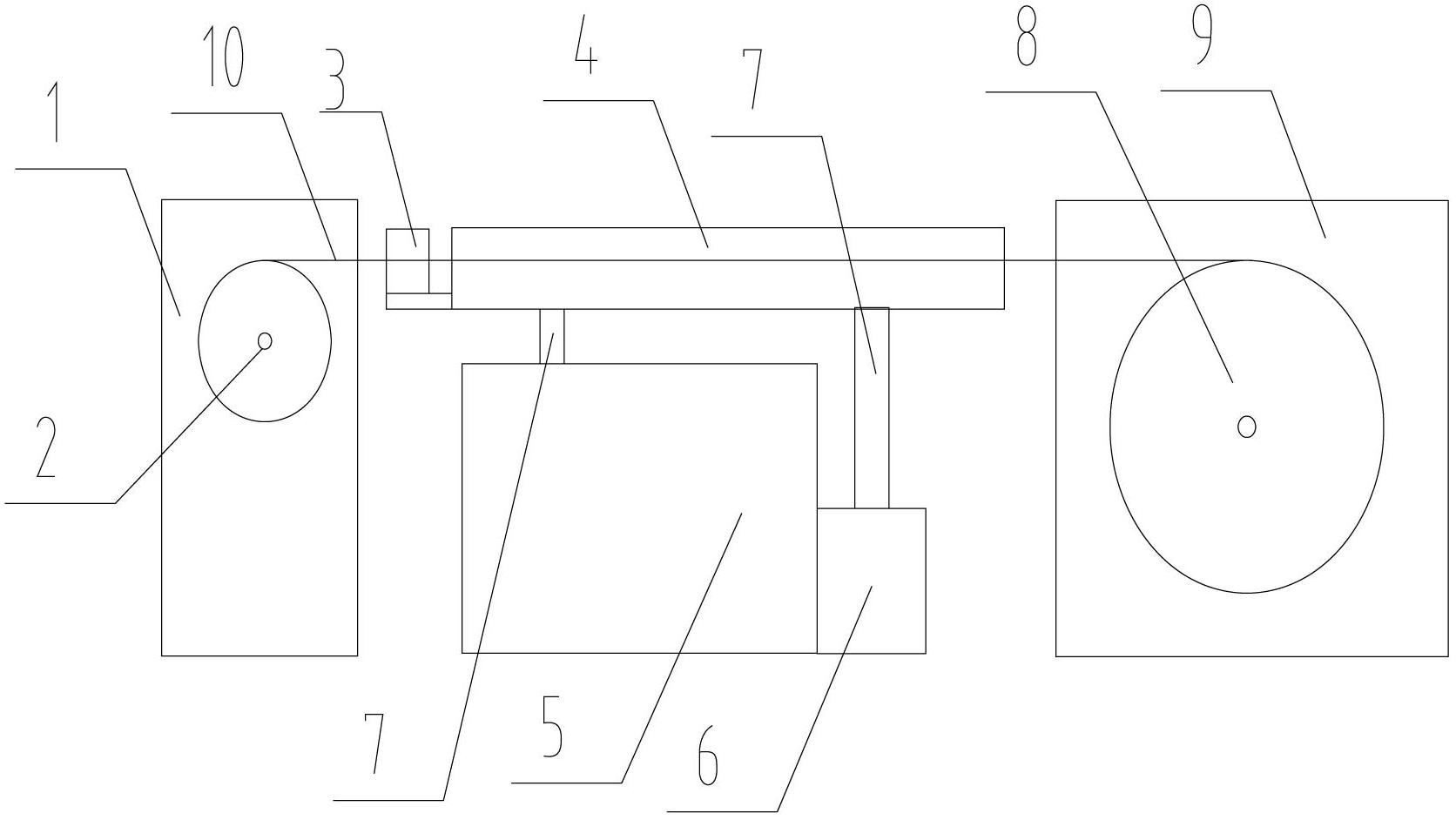

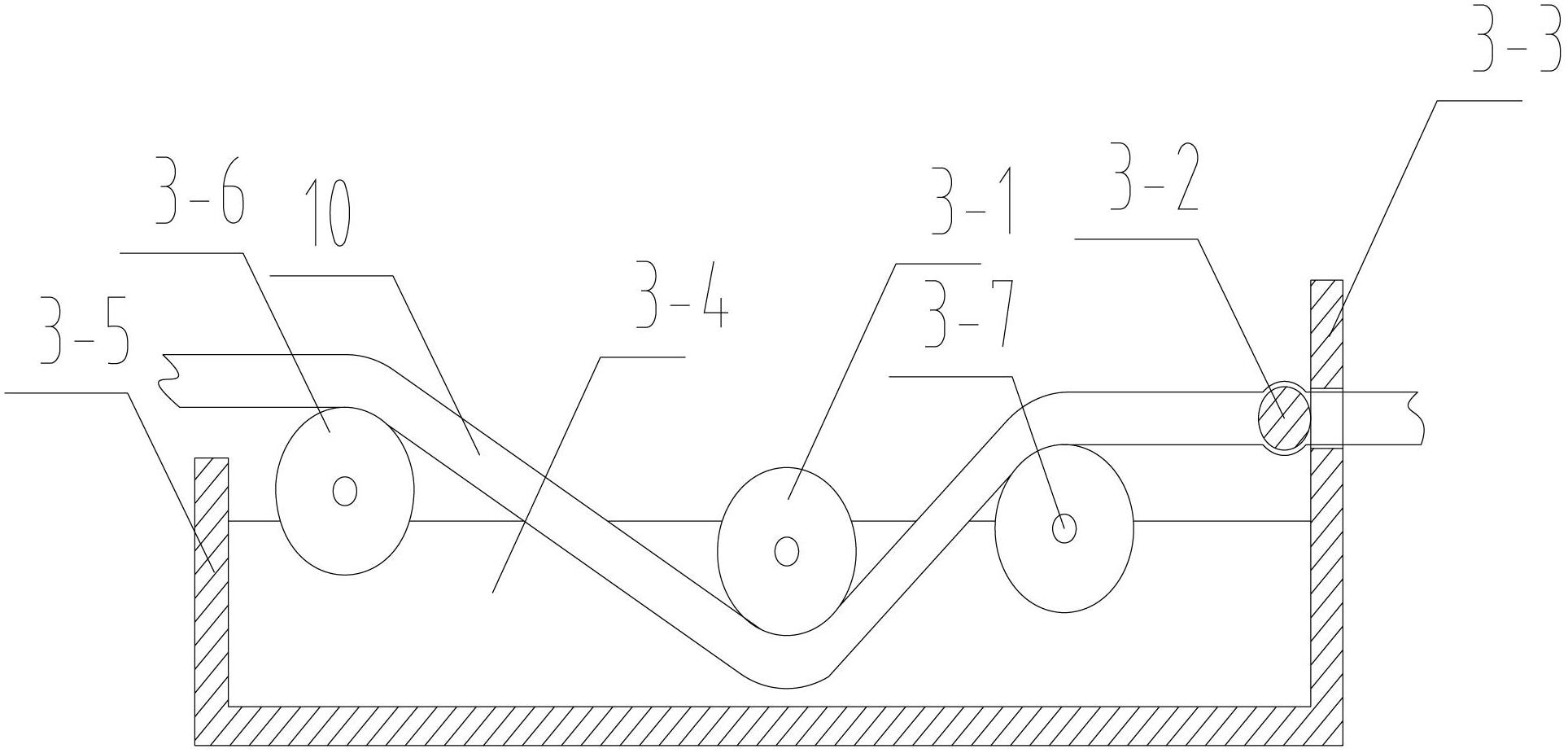

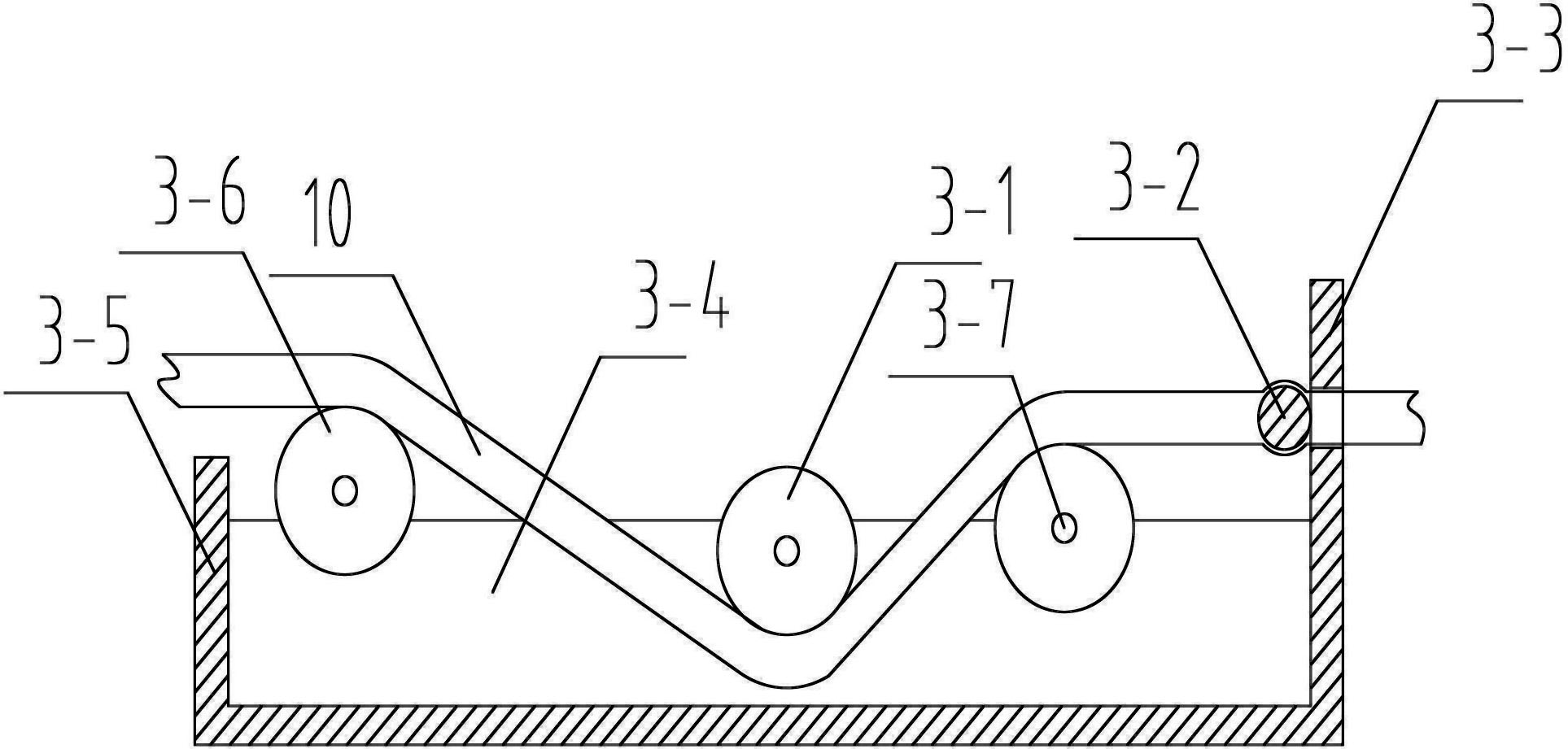

[0026] Referring to the accompanying drawings, the present invention is a set of reinforced hollow fiber membrane production device adopting forming, which is mainly used in the production stage of reinforced hollow fiber membrane, including a wire feeder 1, a horizontal water tank 4, and a wire receiving machine arranged in sequence to transport fiber ropes. 9. There is a fiber roller 2 inside the wire feeder 1, and a wire receiving wheel 8 inside the wire feeder 9. There is also a billet coating device 3 between the wire feeder 1 and the horizontal water tank 4. The billet coating device 3 includes A container 3-5 containing the casting solution 3-4, the container 3-5 is provided with a wire feeding guide wheel 3-6, a wire pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com