Closed galvanizing method for stamping two ends of steel pipe

A steel pipe and two-end technology, which is applied in the field of stamping and closed galvanizing at both ends of the steel pipe, can solve the problem of residual impurities in the pipe body, and achieve the effect of reducing the probability of corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

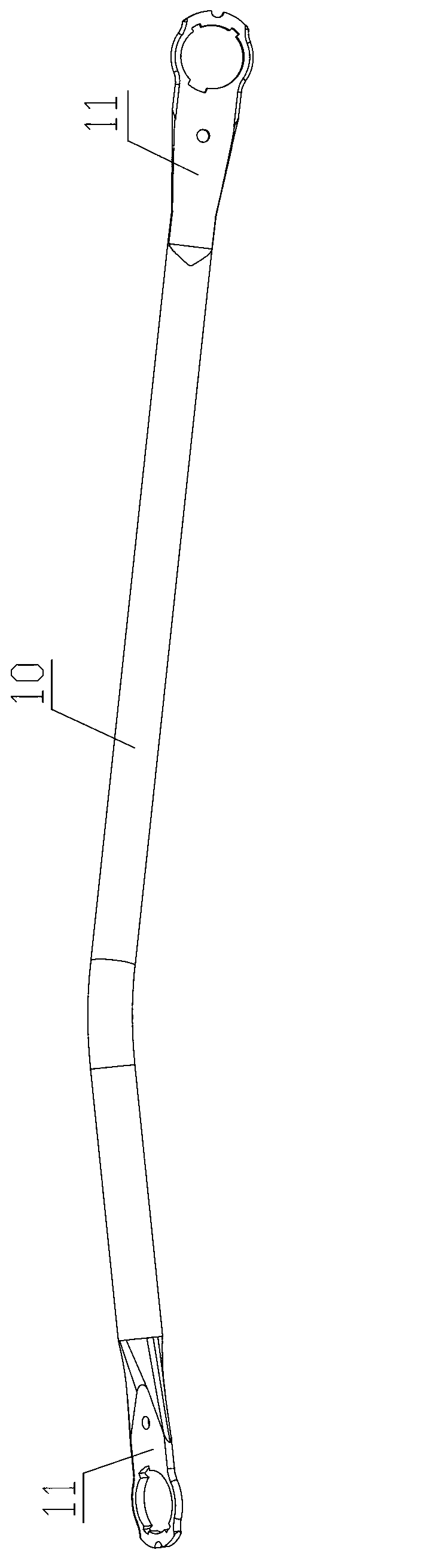

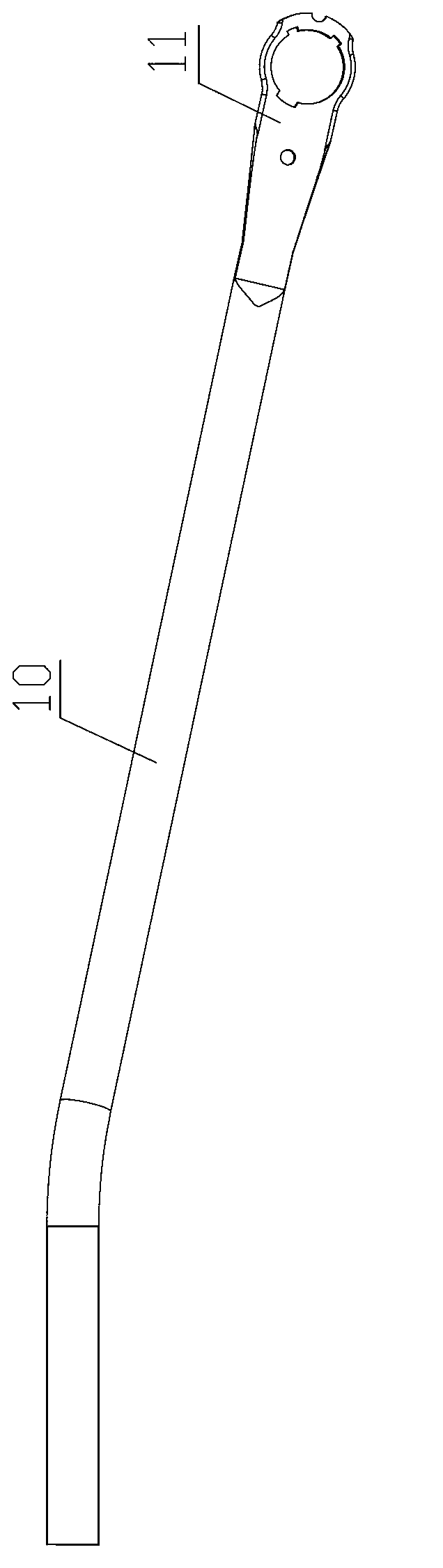

[0015] Examples, see figure 1 and figure 2 Shown: the two-end stamping and sealing galvanizing method of steel pipes is used for preparing steel pipes such as connecting rods of motor vehicles. The steel pipe includes a pipe body 10 , and after the preparation is completed, the left and right ends of the pipe body 10 are both formed with stamping ends 11 . The steel pipe two-end stamping sealing galvanizing method of the present invention comprises the following steps successively:

[0016] A) Stamping the right end of the tube body 10 to close the right end of the tube body 10 and form a stamped end 11 . That is, the left end of the tube body 10 remains as it is.

[0017] B) Place the tube body 10 into the electroplating solution for galvanizing, and pour out the electroplating solution in the tube body 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com