Magnesium-based inorganic heat insulation coating and preparation method thereof

A thermal insulation coating and inorganic technology, applied in the field of magnesium-based inorganic thermal insulation coatings and their preparation, can solve the problems of corrosion of inorganic thermal insulation coatings and limited application fields, and achieve the effects of convenient packaging and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Take 0.35 parts of activated magnesium oxide and 0.035 parts of titanium dioxide and mix them evenly to prepare component A; take 0.15 parts of magnesium sulfate and 0.0018 parts of potassium dihydrogen phosphate and dissolve them in 0.46 parts of water to prepare component B.

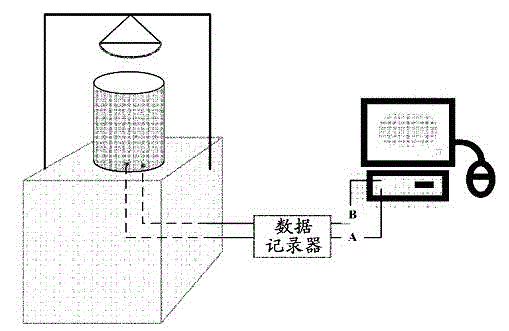

[0050] Mix component A and component B, stir evenly, and spray on a 20×20×6mm fiber cement board, the surface drying time is 35min, and the coating thickness is 0.5mm. After the coating is cured, the storage stability, scrub resistance, water resistance, alkali resistance, temperature change resistance and artificial aging resistance are all qualified according to JG / T 26-2002. according to figure 1 In the shown device, after being irradiated with infrared light for 90 minutes, the measured temperature of the lower surface of the fiber cement board is 53.0°C; under the same conditions, the temperature of the lower surface of the uncoated fiber cement board is 74.4°C.

Embodiment 2

[0052] Take 0.24 parts of activated magnesium oxide and 0.024 parts of functional materials (0.014 parts of hollow glass microspheres and 0.01 parts of lithopone), mix well, and prepare component A; take 0.14 parts of magnesium sulfate and 0.0012 parts of phosphoric acid and dissolve them in 0.60 parts of water to prepare B component.

[0053] Mix component A and component B, stir evenly, and spray on a 20×20×6mm fiber cement board, the surface drying time is 30min, and the coating thickness is 0.5mm. After the coating is cured, the storage stability, scrub resistance, water resistance, alkali resistance, temperature change resistance and artificial aging resistance are all qualified according to JG / T 26-2002. according to figure 1 In the device shown, after irradiating with infrared light for 90 minutes, the temperature of the lower surface of the fiber cement board was measured to be 56.7°C.

Embodiment 3

[0055] Take 0.19 parts of activated magnesium oxide, 0.19 parts of functional materials (0.05 parts of hollow ceramic microspheres, 0.05 parts of hollow glass microspheres, 0.05 parts of titanium dioxide, 0.048 parts of lithopone and 0.001 parts of iron oxide black pigment) and 0.0009 parts of citric acid, Mix evenly to prepare component A; dissolve 0.048 parts of magnesium sulfate in 0.57 parts of water to prepare component B.

[0056] Mix component A and component B, stir evenly, and spray on a 20×20×6mm fiber cement board, the surface drying time is 32min, and the coating thickness is 0.5mm. After the coating is cured, the storage stability, scrub resistance, water resistance, alkali resistance, temperature change resistance and artificial aging resistance are all qualified according to JG / T 26-2002. according to figure 1 In the device shown, after irradiating with infrared light for 90 minutes, the temperature of the lower surface of the fiber cement board was measured to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com