Special shaped block and retaining wall

A block and special-shaped technology, applied in the field of block-stacked walls, can solve problems such as excessive material consumption, complicated construction, and long construction period, and achieve the effects of simple stacking, material saving, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

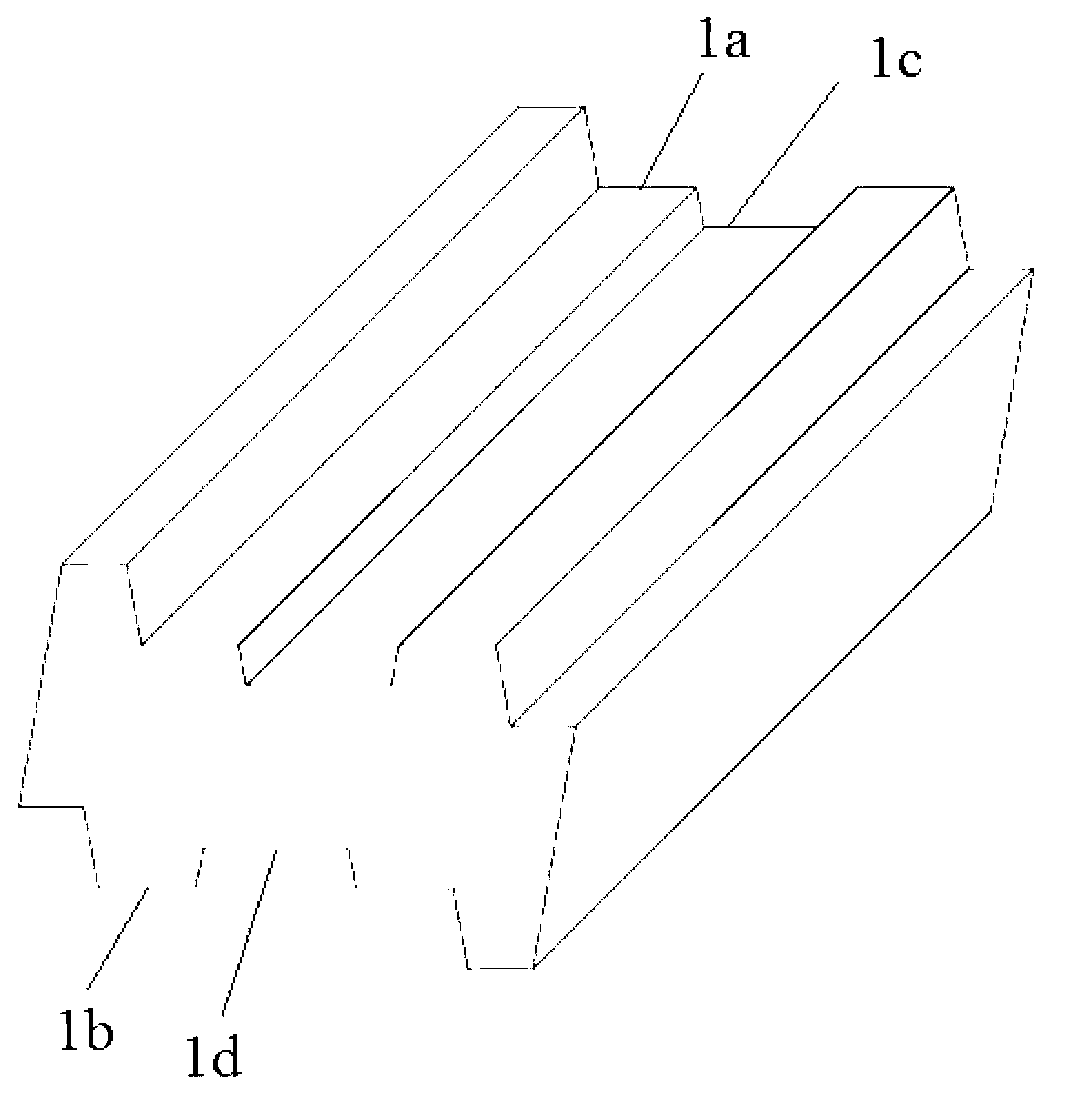

[0028] see figure 2 , the difference between this embodiment and Embodiment 1 is:

[0029] 1. In the special-shaped block in this embodiment, a central groove 1c is provided on the upper surface 1a of the main body, and a central groove 1d is provided on the lower surface 1b of the main body. Setting the central groove can reduce the weight of special-shaped blocks;

[0030] 2. In this embodiment, the bottom of the first protrusion is lower than the transverse central plane of the main body, and correspondingly, the top of the second protrusion is higher than the transverse central plane of the main body.

[0031] For the special-shaped blocks given in the above examples, in the actual implementation process, according to actual needs, different first protrusions and second protrusions can be selected. For example, the bottom of the first protrusion is lower For special-shaped blocks on the transverse central plane of the main body and the top of the second protrusion is hi...

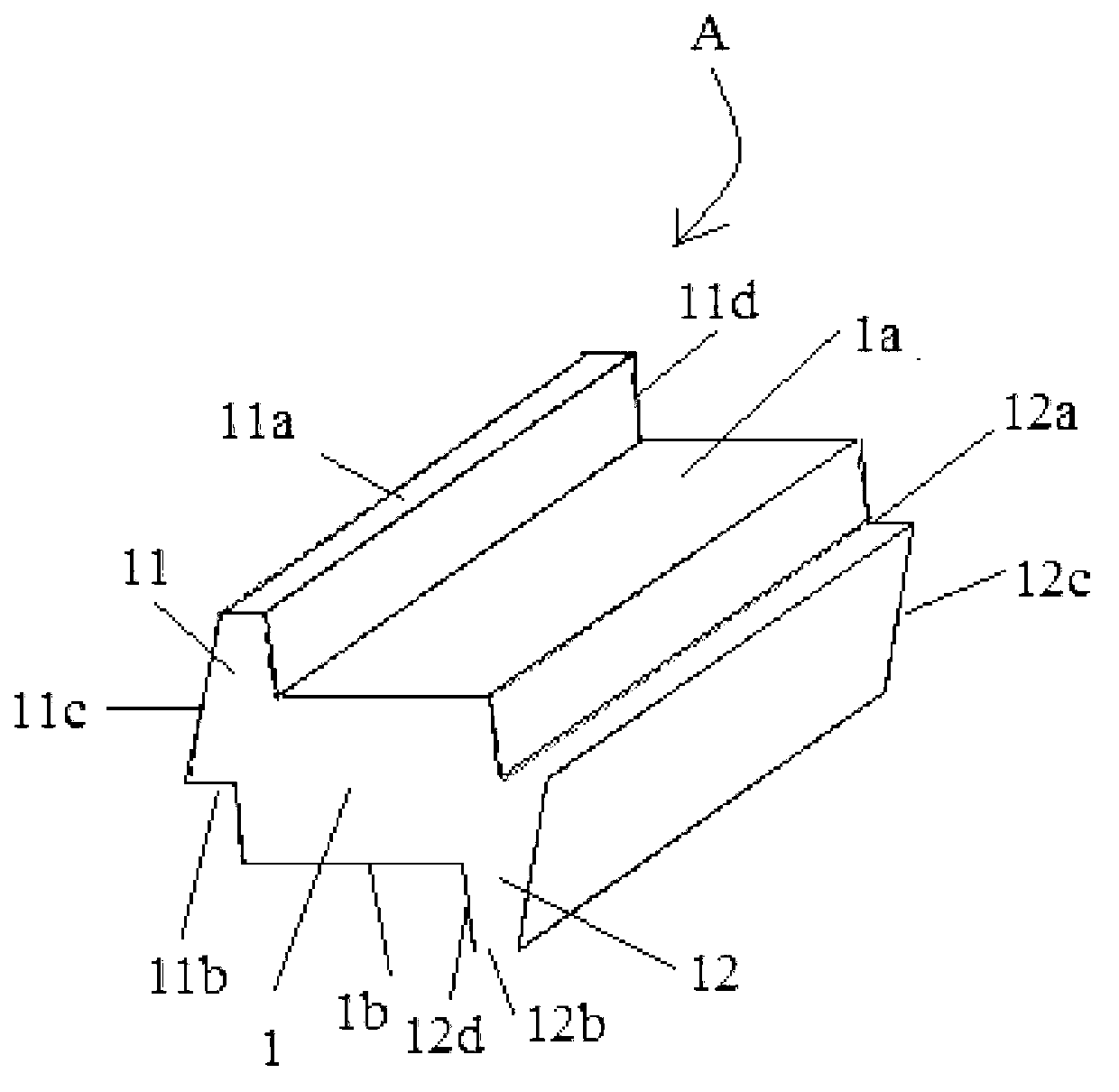

Embodiment 1

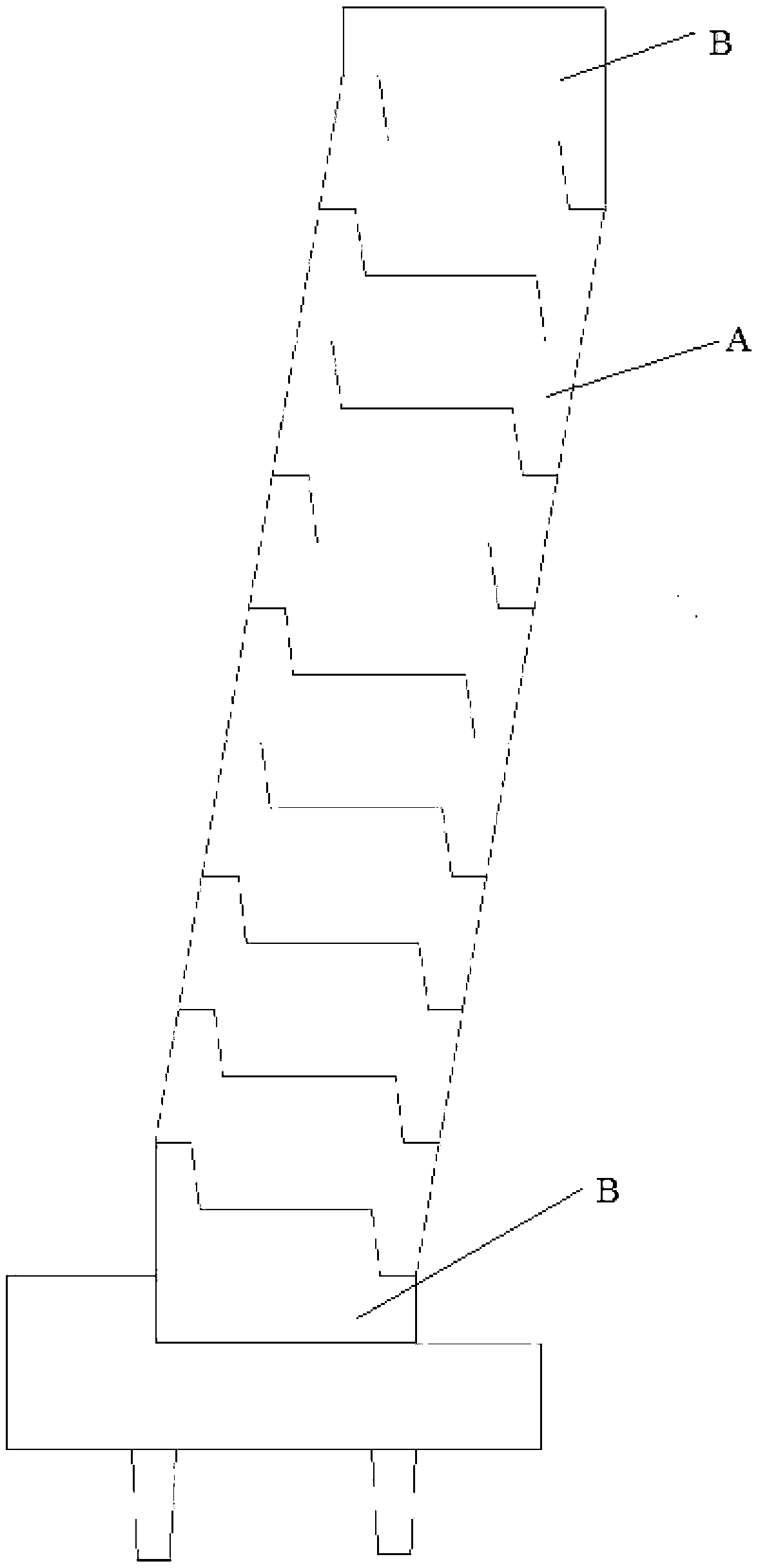

[0033] see image 3 , the retaining wall in this embodiment is composed of several special-shaped blocks to form the main body of the wall, and an end block B is respectively arranged at the top and bottom of the main body of the wall; wherein, the structure of the special-shaped block A in this embodiment The structure is the same as that of the special-shaped block in the first embodiment of the above-mentioned special-shaped block, and will not be repeated here.

[0034] The retaining wall formed by stacking the above special-shaped blocks will form a number of ecological holes when it is sparsely laid. The resulting retaining wall has the functions of self-retaining and self-draining. The retaining wall is weakened and collapsed, and sand-free concrete positioning blocks are placed behind each ecological hole as a filter.

[0035] Example 2 of the retaining wall

[0036] see Figure 4 , the retaining wall in this embodiment is composed of several special-shaped blocks A...

Embodiment 3

[0038] see Figure 5 , the retaining wall in this embodiment is composed of several special-shaped blocks A to form the main body of the wall, and an end block B is respectively arranged at the top and bottom of the main body of the wall; wherein, the first block of the special-shaped block in this embodiment The outer parts of the first protrusion and the second protrusion are slopes at an angle of 45 degrees to the horizontal plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com