Connecting device for reinforcing steel wire rope net sheets and manufacturing method thereof

A technology of wire rope mesh and connecting device, which is applied in the direction of building reinforcements, structural elements, building components, etc., and can solve problems such as unreliable connection methods, easy slipping of fixed collars, and inability to stretch construction of the wire rope mesh system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

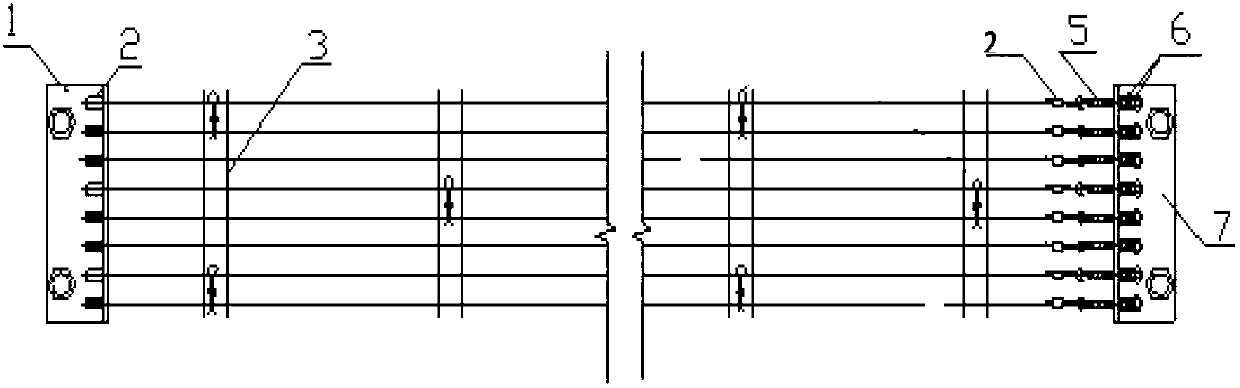

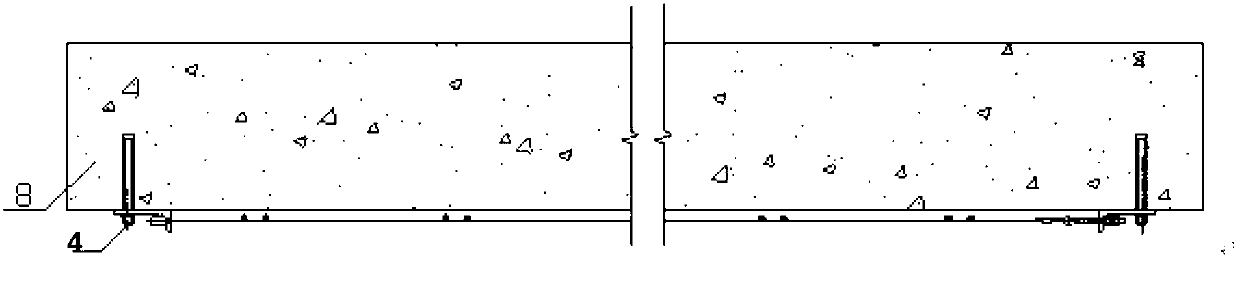

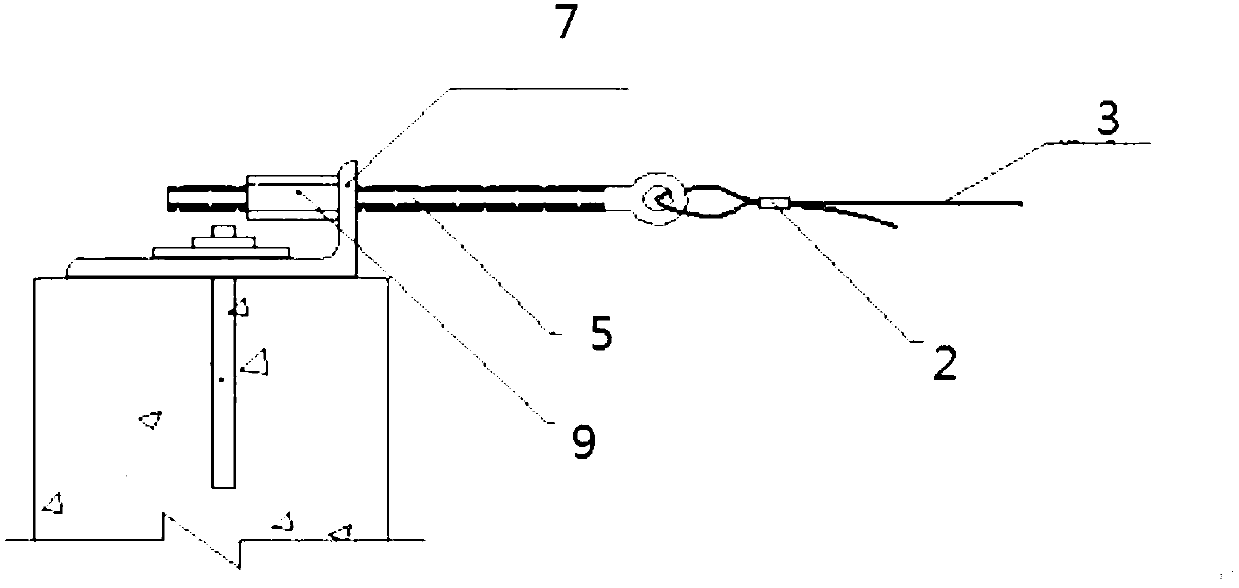

[0022] The invention provides a connection device for reinforcing steel wire rope mesh, which is mainly composed of a fixed end anchor plate 1, a tension end anchor plate 7, a steel wire rope mesh 3, a pressure ring 2 and a special pull rod 5, the fixed end anchor plate 1 and the tension end The end anchor plate 7 is fixed on the two ends of the member 8 to be reinforced, and one end of the wire rope mesh sheet 3 passes through the opening on the fixed end anchor plate 1 and is fixed by the pressure ring 2, and the other end is connected with the special pull rod 5, and the special pull rod 5 passes through the tension ring 2. Pull the end anchor plate 7 and fix it, a section of the special tie rod 5 is provided with an opening, one end of the steel wire mesh sheet 3 passes through the opening of the special tie rod 5 and is fixed by the pressure ring 2, and the other section of the special tie rod 5 is fixed on the On the anchor plate 7 of the tension end, the anchor plate 1 o...

Embodiment 2

[0024] The invention provides a method for manufacturing a connecting device for reinforcing steel wire rope mesh, comprising the following steps:

[0025] (1) Fix the fixed-end anchor plate 1 and the tension-end anchor plate 7 on both ends of the member 8 to be reinforced;

[0026] (2) A section of steel wire mesh piece 3 passes through the opening on the anchor plate 1 at the fixed end, and is fixed with the pressure ring 2;

[0027] (3) The other end of the wire rope mesh sheet 3 is connected with the special pull rod 5, and the special pull rod 5 passes through the tension end anchor plate 7 and is fixed thereon.

[0028] One section of special-purpose pull rod 5 is provided with perforation, and one end of steel wire mesh sheet 3 passes through the perforation of special-purpose pull rod 5 and is fixed by pressure ring 2, and the other section of special-purpose pull rod 5 is fixed on the tension end anchor plate 7 by adjusting nut 9.

[0029] The anchor plate 1 at the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com