Oil filling device of vacuum rotating seal pump

A technology of oil injection device and vacuum rotation, which is applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids, and can solve problems such as decreased sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

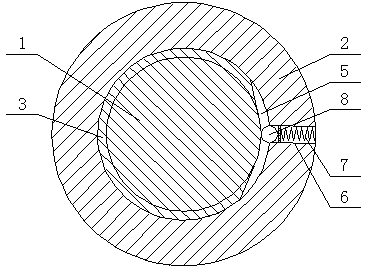

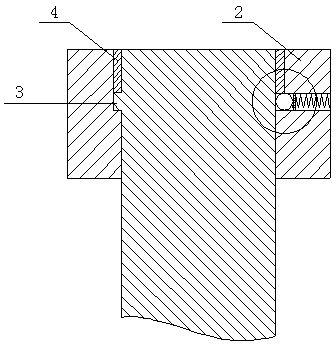

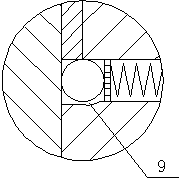

[0012] like Figure 1-3 As shown, the oil filling device of the vacuum rotary seal pump according to the embodiment of the present invention includes a rotating main shaft 1 and a shaft sleeve 2, and an annular boss 3 is provided on the surface of the rotating main shaft 1. There is a sleeve seal 4, the sleeve seal 4 is located between the rotating main shaft 1 and the shaft sleeve 2, the boss 3 is provided with a partial gap 5, corresponding to the boss 3 in the shaft sleeve 2 There is an oil inlet hole 6 on the top, and a ball 8 supported by a spring 7 is installed in the oil inlet hole 6. The diameter of the ball 8 is the same as the diameter of the oil inlet hole 6, and the oil inlet hole at the lower part of the ball 8 is opened. There is an inclined oil inlet 9.

[0013] The shaft sleeve 2 is fixed with the external fixing device, and the shaft sleeve 2 itself does not rotate.

[0014] When part of the notch of the boss is in contact with the ball, the ball will be pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com