Drop test machine of electric iron

A drop test, electric iron technology, applied in impact test, machine/structural component test, measurement device and other directions, to achieve the effects of convenient operation, simple and compact structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

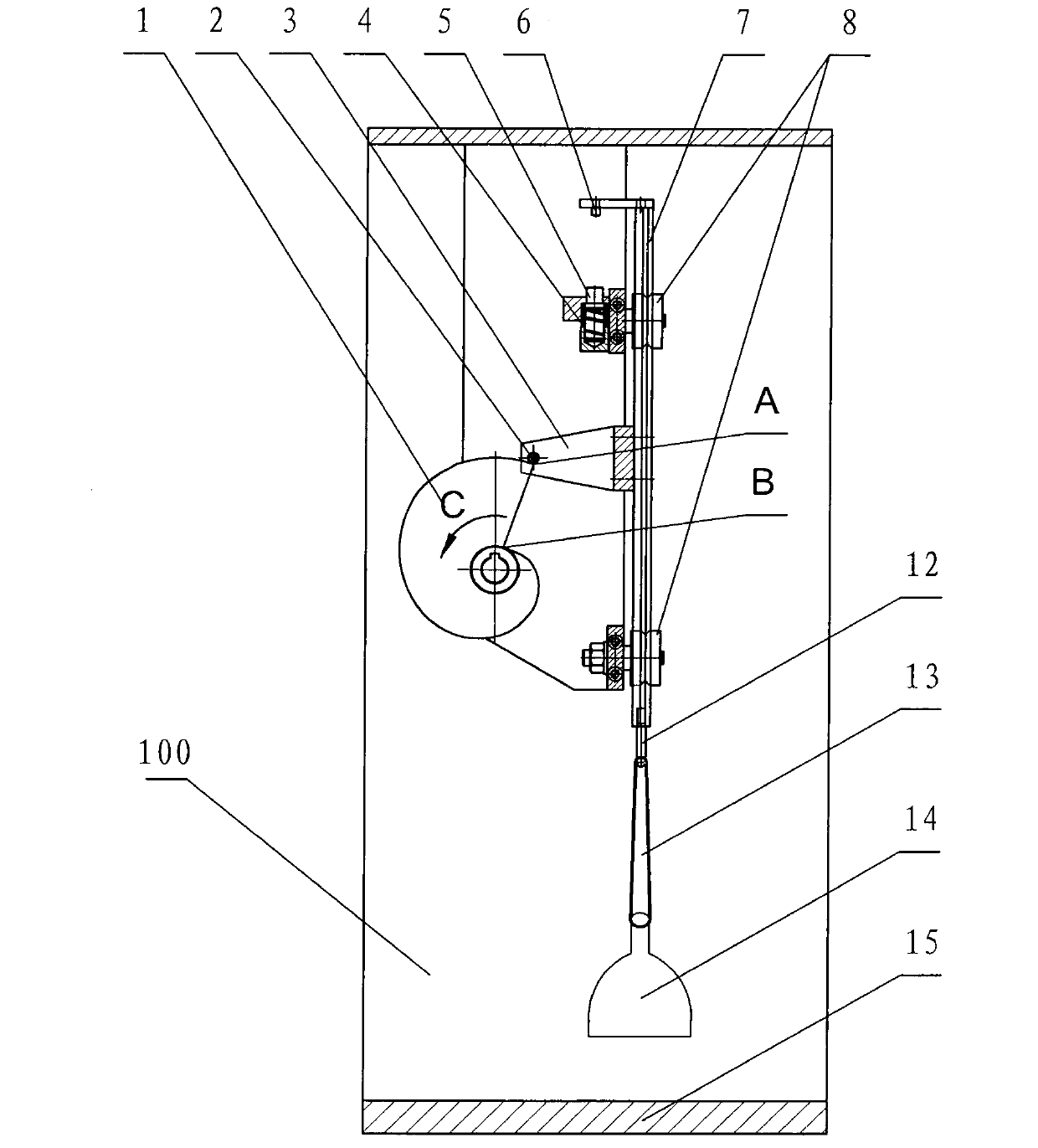

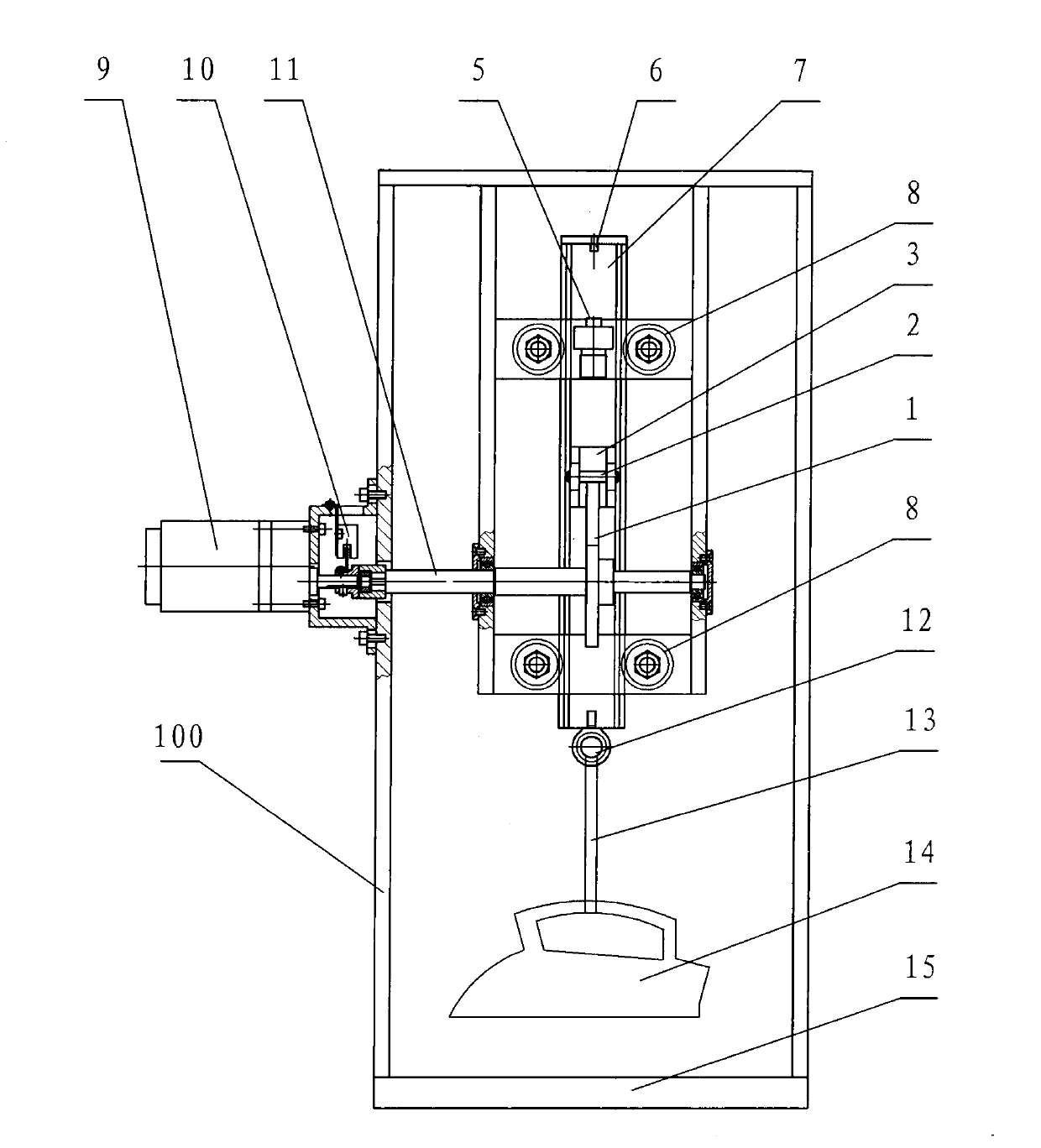

[0016] Such as figure 1 , 2 Shown, the present invention comprises frame 100, and 4 guide rollers 8 are installed on the frame 100, and the bottom of frame 100 is provided with supporting steel plate 15, and the slide block 7 that slides up and down is slidably installed between guide rollers 8. The middle part of the slide block 7 is connected with a slide arm 3, and the front end of the slide arm 3 is provided with a pin shaft 2, which is offset against the cam 1 rotatably installed on the frame 100, and between the high point A and the low point B of the cam 1 The distance should usually be greater than 40 mm. In this embodiment, the distance between the high point A and the low point B of the cam 1 is 55 mm. The cam 1 is connected to the speed regulating motor 9 through the cam shaft 11, and the output shaft of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap