Micro friction force measuring device

A measuring device and micro-friction technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems such as difficulty in achieving the accuracy of friction sensors, coupling between axes, affecting the accuracy of friction measurement results, etc. The effect of system friction, reducing the effect of coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The micro-friction measurement device provided by the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

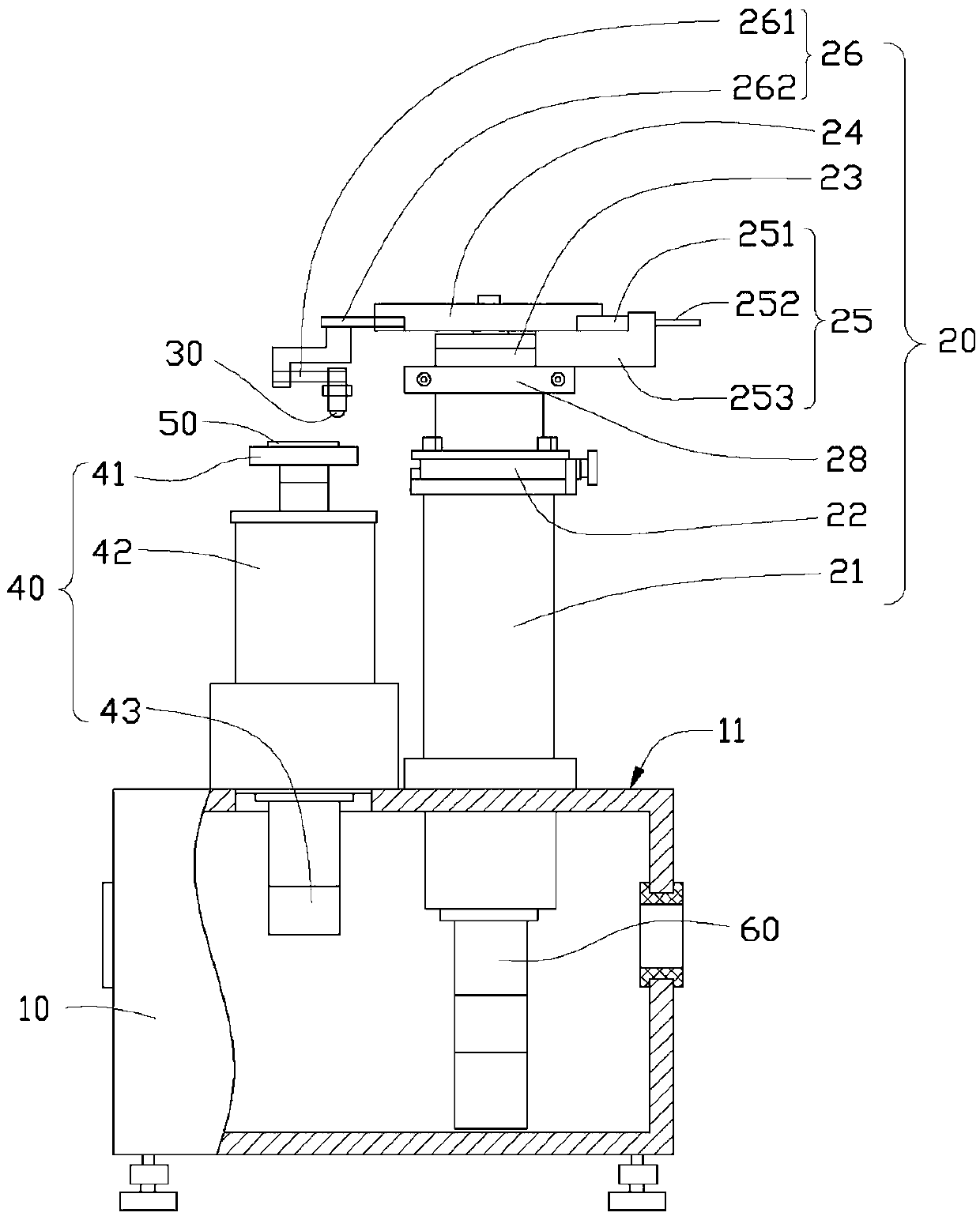

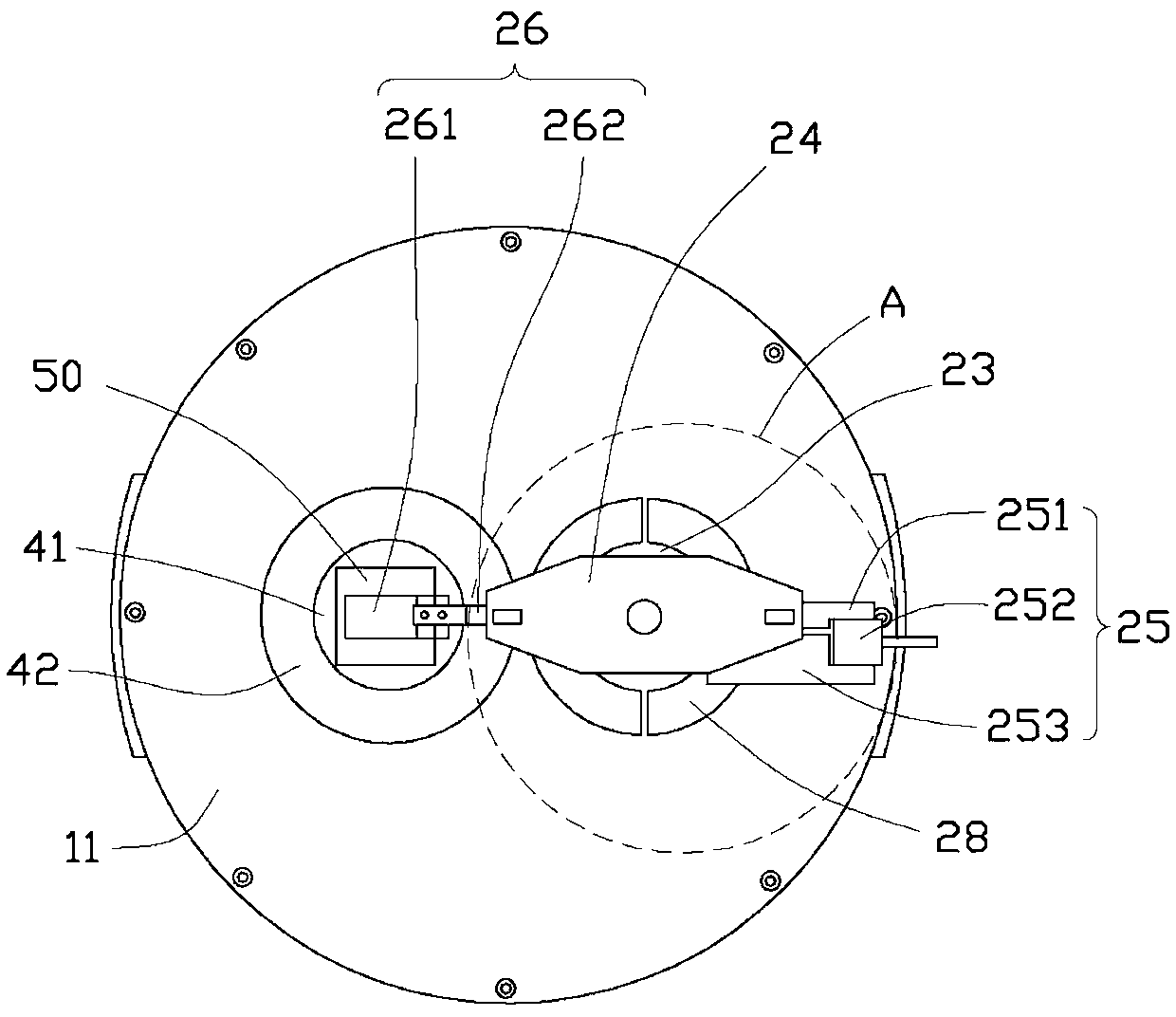

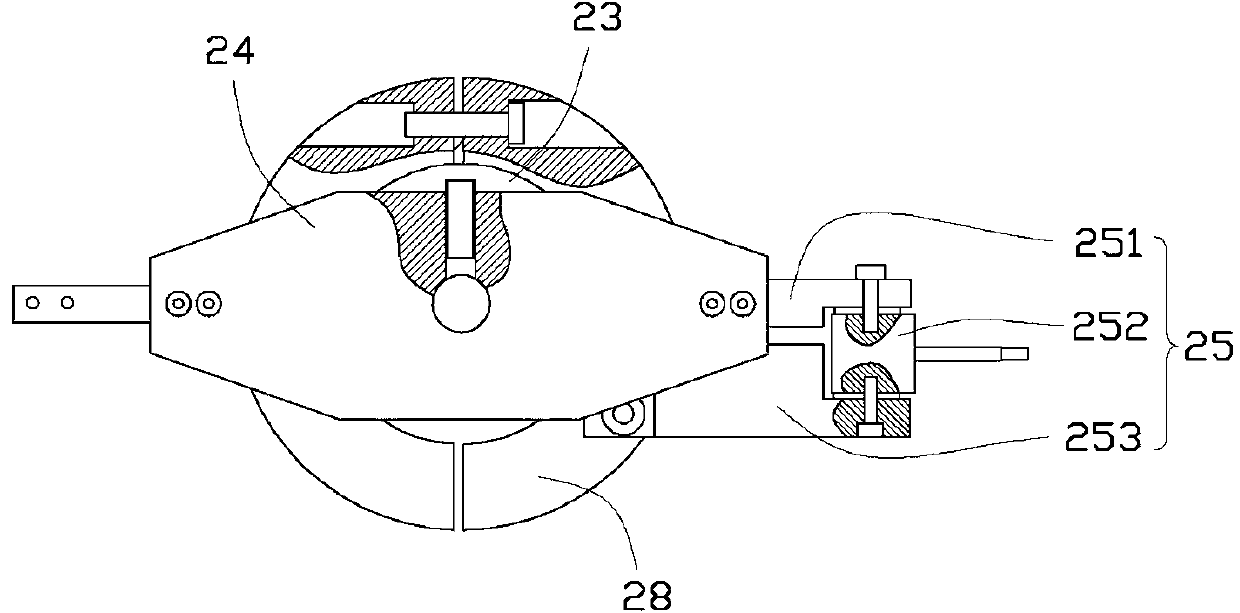

[0024] Please refer to figure 1 , the embodiment of the present invention provides a micro-friction measurement device 100, which is used to measure the micro-friction force of two samples. The micro-friction measurement device 100 includes a frame 10, and an upper The sample carrying unit 20 and the lower sample carrying unit 40 . The upper sample carrying unit 20 and the lower sample carrying unit 40 are used to contact the upper sample and the lower sample and generate relative displacement and relative rotation in the horizontal direction, so that micro-friction occurs between the two samples, and then the micro-friction is tested by the measuring unit. friction.

[0025] The frame 10 includes a table top 11, preferably, the table top 11 is a planar structure.

[0026] Such as figur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap